Cummins QSB 6.7 Parts - Marine Water Pump Section

Loading...

Loading... -

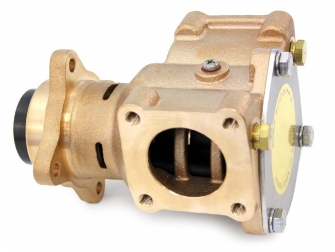

Marine Water Pump for Cummins B, C, QSB and QSL Engines

P1730C

NEW, Bronze seawater pump with 11° off-center shaft mounting holes; Port type: flange, 1 3/4" inlet/outlet; for Cummins B, C, QSB and QSL marine engines.

Price: $ 1,066.25 -

Marine Water Pump for Cummins B, QSB and C Series Marine Engines

S7608

NEW, Bronze high-flow seawater pump; Port type: flange, 1 3/4" inlet/outlet; for Cummins B, QSB and C Series marine engines.

Price: $ 1,139.67 -

-

Cummins Impeller for Splined Shaft

27000K

12 blades, 2 7/8" depth, 3 5/12" diameter, 3/4" shaft diameterPrice: $ 138.53 -

-

Impeller Puller for Marine Water Pumps

50070

Fit range: 2 9/16" to 4 5/8" diameter impeller puller for marine water pumps.

Price: $ 345.12 -

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 20.77 -

Zinc for Marine Engine - for Marine Water Pumps

E2C

For Detroit heat exchanger For Cummins heat exchanger and aftercooler For Brass plug NPT 1/2", zinc length 2"Price: $ 27.53 -

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a cooland and fuel Hose

5104592

Effective Diameter Range:

Minimum 1", Maximum 1.5"

Price: $ 4.52 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 16.50 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 16.68 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 17.19 -

-

Controls Cables & More...

-

Marine Control

-

Industrial Cable

-

Marine Cables 1/16 thread

-

Marine Cables 1/4 thread

-

Marine Steering

-

Rubber Bearing

-

Searchlight

-

Marine Bulb

-

Navigation Light

Cummins QSB 6.7 Marine Water Pump & Cooling System Components

The Cummins QSB 6.7 engine is one of the most trusted powerplants for marine applications around the world. Known for its high-efficiency combustion, clean emissions profile, and compact footprint, the QSB 6.7 is frequently used in commercial boats, patrol craft, fishing vessels, and auxiliary power systems.

Central to the engine’s thermal management is the marine water pump system—also known as the raw water or sea water cooling circuit. This system draws seawater through a strainer, pushes it through a heat exchanger, and discharges it with the engine's exhaust. On this page, you'll find all essential components related to the QSB 6.7's marine water pump system, including the raw water pump, impeller, gaskets, hoses, strainers, clamps, anodes, and servicing tools.

Marine Water Pumps for Cummins QSB 6.7 Engines

Raw Water Pump for Cummins B, C, QSB, and QSL Marine Engines

Our featured marine water pump is compatible with Cummins QSB 6.7 as well as other B, C, and QSL series engines. This pump is ideal for marine installations where robust cooling performance and bidirectional operation are critical.

Key Features:

-

Bidirectional Operation: This water pump rotates either clockwise or counterclockwise, making it suitable for both port and starboard engine configurations or generator sets.

-

Mounting Hole Offset: 11° offset from the center of the drive gear shaft for optimal alignment on Cummins marine engine front plates.

-

Port Type: 1¾” flange connections ensure secure hose integration with minimal risk of vibration-induced leaks.

This pump is widely used on marine engines that operate in continuous-duty or variable-load conditions. It provides the necessary seawater flow to cool high-output engines, even during extended full-throttle operation.

Sea Water Pump for Cummins QSB 5.9 and QSB 6.7 (S7608 Series)

This variation of the marine water pump is also fully compatible with the QSB 6.7 and offers a rugged design optimized for marine environments. Built from corrosion-resistant materials, this model provides high volume flow and long service life.

Design Specifications:

-

Bidirectional Pumping: Supports both right-hand and left-hand shaft rotation

-

Marine-grade Bronze Housing: Withstands saltwater corrosion

-

1¾” Flanged Ports: Consistent across QSB cooling configurations

These pumps are especially favored for commercial operators who demand long service intervals and high resistance to salt-induced wear.

Impellers for Cummins QSB 6.7 Water Pumps

12-Blade Impeller for Splined Shaft Pumps

Impellers are among the most frequently serviced components in the marine cooling system. This splined shaft impeller is specifically engineered for Cummins QSB 6.7 water pumps:

-

Blade Count: 12 rubberized blades provide balanced seawater flow

-

Depth: 2⅞"

-

Diameter: 3-5/12"

-

Shaft Diameter: Fits ¾” splined pump shafts

Regular inspection of the impeller ensures your raw water pump maintains proper suction and flow. Replace any impeller showing signs of cracking, chipping, or hardening due to heat exposure.

Gaskets and Seals for Marine Pump Installations

Marine Water Pump Mounting Gasket

A proper seal between the water pump and the engine block is critical. This gasket is engineered for the vibration, thermal cycling, and exposure to saltwater typical in marine environments. Replace it whenever the pump is removed or serviced.

Marine Water Pump O-Rings

Each QSB 6.7 pump includes O-rings on both the inlet and outlet ports. These provide a watertight seal and prevent saltwater from seeping into the engine compartment.

-

Set Includes: Two O-rings per engine (one inlet, one outlet)

-

Materials: Marine-rated rubber compounds for durability

Failing to replace these during service can lead to leaks and cooling loss over time.

Impeller Puller Tool for QSB Water Pumps

Servicing marine impellers without damaging them or the pump housing requires the right tool. The marine impeller puller is a staple for onboard maintenance and professional repair facilities.

Tool Benefits:

-

Non-Destructive Removal: Eliminates prying or blade tearing

-

Stainless Steel Construction: Marine-safe and corrosion resistant

-

Universal Compatibility: Works with most impellers used in Cummins QSB and Detroit Diesel water pumps

Carry this tool onboard as part of your essential marine maintenance kit.

Zinc Anodes for Corrosion Protection

Zinc for Heat Exchangers and Aftercoolers

Galvanic corrosion is a major threat to any saltwater-cooled system. Sacrificial zinc anodes are essential for protecting your QSB 6.7’s heat exchanger, aftercooler, and fuel/oil cooling components.

-

Heat Exchanger Zinc: For brass plugs with NPT ½” threads, 2" length

-

Fuel/Oil Cooler Zinc: For smaller NPT ⅜” brass plugs, 1" length

Replace zincs regularly. When more than 50% of the material has eroded, performance is compromised, and system corrosion may follow.

Intake Water Strainers for Marine Cooling

Strainers act as the first line of defense in the seawater cooling circuit. They prevent debris such as sand, kelp, and shells from entering the water pump or heat exchanger.

Available Sizes:

Each strainer includes:

-

Corrosion-resistant housing

-

Transparent inspection cover

-

Fine mesh filter screen

-

Removable basket for easy cleaning

Install the correct size strainer based on your sea water pump inlet size to prevent flow restriction.

Silicone Marine Coolant Hoses

Coolant hoses deliver seawater from the pump through the heat exchanger and back to the exhaust or discharge. Silicone hoses are the preferred option in marine applications due to their flexibility, pressure resistance, and thermal stability.

All hoses are 1-foot in length and available in the following inside diameters:

-

1”

-

1¾”

-

1⅞”

-

2”

-

2⅛”

-

2¼”

-

2⅜”

-

2½”

-

2¾”

-

3”

-

3½”

-

4”

These hoses are reinforced to resist collapse under suction and high engine bay temperatures. Periodic inspection is recommended—especially near bends or clamp points.

Hose Clamps for QSB 6.7 Marine Hoses

Each coolant hose must be secured with marine-grade clamps to prevent leaks and ensure long-term integrity of the system.

Stainless Clamp Sizes:

-

Clamp 3412320: 11/16" to 1¼"

-

Clamp 4920417: 13/16" to 1¾"

-

Clamp 5104592: 1" to 1.5"

-

Clamp 3922846: 1-5/16" to 2¼"

-

Clamp 3922847: 1-9/16" to 2½"

-

Clamp 3922847 (Large): 2-5/16" to 3"

All clamps feature:

-

Worm-gear tightening

-

Rounded band edges to protect hose integrity

-

100% stainless steel for rust prevention

Replace clamps any time you observe corrosion or weakening, particularly near heat sources.

QSB 6.7 Cooling System Operation Overview

How the Raw Water System Works

-

Seawater Intake: Water is drawn from the sea through a through-hull fitting and intake strainer.

-

Raw Water Pump: The pump pushes seawater through the system using an impeller-driven mechanism.

-

Heat Exchanger: The seawater absorbs heat from the engine coolant through metal plates or tubes.

-

Exhaust Mixing Elbow: After cooling the engine, the seawater is injected into the exhaust system to cool and discharge it overboard.

If any part of this system is compromised—impeller wear, hose cracks, or zinc corrosion—engine overheating or seawater leaks may result.

Preventative Maintenance Schedule

To maximize uptime and extend the life of your Cummins QSB 6.7, follow these marine cooling system maintenance best practices:

|

Component |

Interval |

Maintenance Action |

|

Raw Water Pump |

500 Hours or Annually |

Inspect housing, bearings, and seals |

|

Impeller |

200-300 Hours |

Replace if worn or hardened |

|

O-Rings and Gaskets |

At Every Service |

Replace to ensure leak-proof operation |

|

Zinc Anodes |

Every 3 Months |

Replace if 50% worn |

|

Coolant Hoses |

Annually |

Check for softness, swelling, or cracks |

|

Hose Clamps |

Annually |

Inspect for rust, replace if pitted |

|

Strainer Basket |

Monthly |

Remove and clean debris |

Failure to follow this schedule can lead to reduced cooling capacity, overheating, or complete system failure.

Real-World Applications of Cummins QSB 6.7 with Marine Cooling Systems

This cooling system layout and component set is used in:

-

Harbor Pilot Boats: Requiring dependable low-RPM cooling and silent operation

-

Commercial Fishing Vessels: Where long idle periods alternate with high-output runs

-

Passenger Ferries: With long daily duty cycles and strict emissions compliance

-

Tugboats & Towboats: Operating under high torque loads in tight marine channels

-

Offshore Generator Sets: Requiring uninterrupted cooling for 24/7 operation

Why Marine Professionals Choose Diesel Pro Power

With over 40,000 customers worldwide, Diesel Pro Power is the trusted source for Cummins marine engine parts—including the QSB 6.7 series. We specialize in:

-

Genuine and aftermarket-compatible marine components

-

Fast global shipping

-

Multilingual customer support

-

Technical expertise in marine-specific installations

Every item in this catalog is backed by our commitment to reliability and marine-grade quality.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588