The Detroit Diesel Series 149 engines are robust two-cycle, V-type diesel engines designed to deliver high power and reliability across demanding applications. They feature a unique two-stroke cycle with an integrated air scavenging system, optimized for sustained, high-performance operation. This configuration provides a favorable weight-to-horsepower ratio, making them ideal for heavy-duty use in various settings.

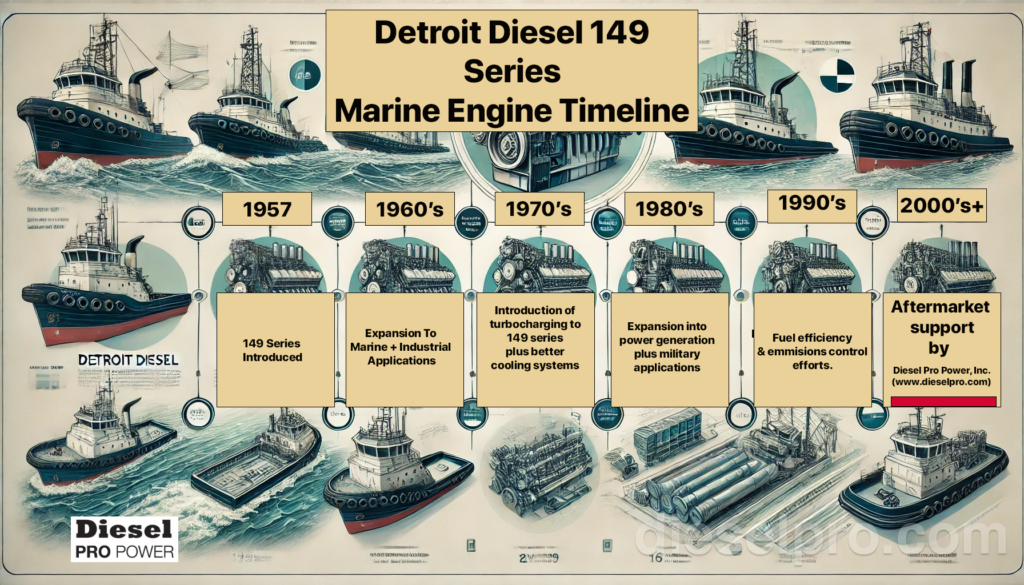

History and Development Of The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

Key Features Of Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

The Detroit Diesel 149 Series engines, available in configurations such as 8V149, 12V149, and 16V149, are engineered with features that prioritize efficiency, power, and durability. These engines were designed to handle continuous, high-load operation, making them ideal for demanding applications across various industries. With innovations focused on operational longevity, ease of maintenance, and reliable power output, the 149 Series engines are well-regarded for their ability to perform in tough conditions.

Two-Cycle Operation

The 149 Series engines operate on a two-stroke cycle, a design that sets them apart from many other diesel engines. The two-stroke process offers a range of benefits, particularly in heavy-duty applications where power density and efficiency are critical.

- Efficient Combustion Process:

Unlike four-stroke engines that require two revolutions for each power stroke, the two-stroke cycle generates a power stroke with every crankshaft revolution. This allows the engine to produce high power output with fewer parts, reducing mechanical complexity and friction, which can improve reliability and longevity.

- High Power Output with Fewer Moving Parts:

The two-stroke cycle design reduces the number of components needed for the combustion process, resulting in fewer parts that are subject to wear. This simplifies maintenance and lowers the risk of part failure, while also enabling the engine to deliver powerful performance in a compact size.

- Compact Design for Space-Constrained Applications:

Because of its simplified operation and higher power density, the two-stroke cycle allows for a smaller engine footprint. This makes the 149 Series particularly useful in applications like marine vessels and industrial equipment, where space is limited but high power is essential.

Scavenging Air System

To facilitate efficient combustion, the Detroit Diesel 149 Series engines are equipped with a scavenging air system, which includes a built-in blower. This system provides the necessary airflow for fuel combustion and is a key factor in the engine’s high power and fuel efficiency.

- Blower-Driven Air Intake:

Blower For Detroit Diesel 12V149

The scavenging air system uses a positive displacement blower to force air into the cylinders, ensuring complete expulsion of exhaust gases during each cycle. This forced airflow is crucial for maintaining combustion efficiency and enabling the two-stroke cycle to operate effectively.

- Enhanced Power and Responsiveness:

By supplying a constant flow of fresh air, the blower supports a rapid response to load changes. This feature is especially valuable in high-load scenarios, such as when marine engines operate under continuous strain or industrial engines encounter variable loads.

- Optimized for Turbocharging:

The scavenging air system works in tandem with turbocharging on select models, allowing the engine to achieve even greater power output. The turbocharger compresses incoming air, increasing its density and ensuring a more complete combustion process. This leads to improved fuel efficiency and enables the engine to maintain power in high-altitude or high-demand applications.

Durable Construction

Detroit Diesel engineered the 149 Series engines with a robust construction to handle the stresses of continuous operation in harsh environments. Key design features, such as individual cylinder heads and free-floating pistons, contribute to the durability and serviceability of these engines.

- Individual Cylinder Heads:

Detroit Diesel 149 Series (8V149, 12V149, 16V149) Cylinder Head

Each cylinder has its own head, which makes servicing individual cylinders easier and more cost-effective. If one cylinder requires maintenance, it can be addressed without dismantling the entire engine. This modular design minimizes downtime and simplifies repairs, making the 149 Series more economical to maintain.

- Free-Floating Pistons:

The engines utilize free-floating pistons that reduce friction and wear, enhancing the durability of the cylinder assembly. This design improves the engine’s operational longevity and reduces the need for frequent piston replacements, particularly in applications with high wear rates.

- Heat-Resistant Materials:

Built with durable materials that withstand high temperatures and pressures, the 149 Series engines are optimized for applications where engines operate under full load for extended periods. The durable construction ensures that components like cylinder heads, pistons, and exhaust valves can resist wear from heat and pressure, which is especially important for marine and industrial uses.

- Corrosion-Resistant Coatings:

Many components are treated with corrosion-resistant coatings, which are essential for engines operating in saltwater environments or areas with high humidity. This added protection prevents rust and material degradation, extending the life of parts exposed to harsh conditions.

High Power Density

The 149 Series engines are designed to provide substantial power output in a compact form factor, making them versatile for a variety of applications. Available in multiple configurations—8V, 12V, and 16V—the engines can meet diverse power requirements, with flexibility to suit different operational needs.

- Multiple Cylinder Configurations:

The 149 Series engines are available in various configurations, allowing operators to choose the setup that best matches their power needs. The 8V, 12V, and 16V configurations provide scalable power options, making the engines adaptable to a range of heavy-duty applications, from industrial equipment to marine propulsion.

- High Power-to-Weight Ratio:

Despite their compact design, the 149 Series engines offer a high power-to-weight ratio, which is crucial in applications where both power and weight are critical considerations. This feature is especially valuable for marine vessels and mobile industrial equipment, where minimizing weight can enhance performance and fuel efficiency.

- Turbocharging for Enhanced Power Output: Turbocharged models of the 149 Series engines further enhance the power density by compressing the intake air, allowing for more fuel to be burned with each cycle. Turbocharging not only increases the engine’s power output but also improves fuel efficiency, making these engines more economical to operate in fuel-demanding applications.

- Versatile Applications Across Industries: The flexible configurations and high power density make the 149 Series engines suitable for a wide array of industries, from marine and industrial to off-highway vehicles. Their ability to provide high horsepower in a compact form makes them a popular choice for applications where space is limited but power requirements are high.

Summary of Key Features

The Detroit Diesel 149 Series engines are engineered with several core features that make them stand out in heavy-duty applications:

- Two-Cycle Operation: Delivers high power output with fewer moving parts, improving reliability and reducing maintenance requirements.

- Scavenging Air System: Provides a steady airflow for efficient combustion, especially important for high-load scenarios and turbocharged models.

- Durable Construction: Built with individual cylinder heads, free-floating pistons, and corrosion-resistant materials for extended operational life and easy serviceability.

- High Power Density: Available in multiple configurations, these engines offer flexible power options in a compact design, meeting diverse power requirements for different applications.

Through these features, Detroit Diesel 149 Series engines provide reliable, powerful performance for industries that demand the most from their equipment. With an emphasis on durability, ease of maintenance, and power efficiency, the 149 Series engines continue to be a preferred choice in challenging environments.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588

Detroit Diesel 149 Series engines are often used in workboats and transport barges that operate in rough conditions or haul heavy loads. These engines provide the consistent power and reliability needed for such demanding operations, ensuring that the vessels can perform their tasks effectively.

Detroit Diesel 149 Series engines are often used in workboats and transport barges that operate in rough conditions or haul heavy loads. These engines provide the consistent power and reliability needed for such demanding operations, ensuring that the vessels can perform their tasks effectively.