Proper disassembly of Cummins ISM, ISMe, and QSM11 engines is essential for effective maintenance, troubleshooting, and complete overhauls. Whether performing a minor repair or a full rebuild, following a structured disassembly process ensures components are removed safely, labeled correctly, and stored properly to prevent damage.

This guide provides a step-by-step approach for disassembling a Cummins ISM, ISMe, or QSM11 engine, covering necessary tools, safety precautions, sequential teardown procedures, and best practices for handling engine components.

For exact torque values, wear limits, and reassembly specifications, refer to an OEM service manual or consult Diesel Pro Power for expert guidance.

Parts Catalog for ISM Cummins Marine and Industrial Engines

Parts Catalog for QSM11 Cummins Marine and Industrial Engines

Safety Precautions Before Engine Disassembly

Disassembling a heavy-duty diesel engine involves handling large, heavy, and high-precision components. Observing proper safety procedures is essential to prevent injuries and avoid damage to engine parts.

Personal Protective Equipment (PPE)

✔ Safety glasses – Protect eyes from debris, pressurized fluids, and small particles.

✔ Mechanic gloves – Prevent cuts, burns, and exposure to hazardous chemicals.

✔ Steel-toe boots – Protect against heavy falling components.

✔ Hearing protection – Recommended when working in a high-noise environment.

Work Area Preparation

- Ensure a clean, well-lit, and organized workspace.

- Drain engine fluids (oil, coolant, and fuel) completely before beginning disassembly.

- Label and store fasteners in separate trays or magnetic parts holders to prevent loss.

- Use an engine stand or hoist to safely support the engine during disassembly.

Essential Tools for Engine Disassembly

✔ Torque wrench – For loosening fasteners with correct force.

✔ Breaker bars and impact tools – For high-torque bolts.

✔ Pry bars and pullers – For separating tightly fitted components.

✔ Oil catch pans – To prevent fluid spills.

✔ Plastic bags and markers – For labeling and storing small parts.

✔ Engine hoist and lifting chains – For handling heavy parts such as the crankshaft and cylinder head.

Step-by-Step Engine Disassembly Procedures

The Cummins ISM, ISMe, and QSM11 engines should be disassembled in a logical sequence, ensuring components are removed in the correct order to prevent damage.

Step 1: Preparation and Engine Removal from Chassis

- Disconnect the Battery:

- Prevents accidental electrical engagement.

- Prevents accidental electrical engagement.

- Drain Fluids Completely:

- Drain engine oil, coolant, and fuel from the system.

- Dispose of fluids properly according to environmental regulations.

- Remove External Accessories:

- Alternator, starter motor, and accessory brackets.

- Power steering pump (if applicable).

- Disconnect Fuel and Air Intake System:

- Remove fuel lines carefully and cap openings to prevent contamination.

- Disconnect turbocharger piping and intake manifold.

- Unbolt Engine from Mounts and Hoist Out:

- Use an engine hoist and proper lifting points to remove the engine safely.

- Use an engine hoist and proper lifting points to remove the engine safely.

Step 2: Cylinder Head Disassembly

The cylinder head contains the valves, camshaft, injectors, and rocker arms. Careful removal is required to avoid damage to delicate components.

- Remove Valve Cover and Rocker Arms:

- Unbolt and remove the valve cover to access the rocker arms and pushrods.

- Label and store pushrods and rockers to ensure correct reinstallation.

- Remove Injectors:

- Loosen injector hold-down bolts evenly to avoid damage.

- Carefully remove injectors without bending or damaging fuel lines.

- Detach the Cylinder Head:

- Loosen head bolts in a crisscross pattern to prevent warping.

- Lift the cylinder head using an engine hoist and place it on a clean workbench.

- Inspect Head Gasket and Combustion Chambers:

- Check for cracks, leaks, or excessive wear in the head gasket area.

- Check for cracks, leaks, or excessive wear in the head gasket area.

Cylinder Head & Related Components for Cummins ISM engine

Cylinder Head & Related Components for Cummins QSM11 engine

Step 3: Timing and Camshaft Disassembly

The camshaft and timing components must be removed carefully to preserve precise engine timing.

- Remove the Timing Cover:

- Unbolt and gently pry open the front timing cover to expose the camshaft gear.

- Unbolt and gently pry open the front timing cover to expose the camshaft gear.

- Extract the Camshaft:

- Rotate the engine to relieve valve spring tension before removing the camshaft.

- Slide out the camshaft carefully to avoid damaging cam bearings.

- Inspect Cam Lobes and Bearings:

- Look for pitting, wear, or cracks in the camshaft lobes and journals.

- Look for pitting, wear, or cracks in the camshaft lobes and journals.

Camshaft & Related Components for Cummins ISM engine

Camshaft & Related Components for Cummins QSM11 engine

Step 4: Cylinder Block and Piston Disassembly

The cylinder block contains the crankshaft, pistons, and bearings, which require precise removal and inspection.

- Remove Oil Pan and Oil Pump:

- Drain remaining oil and unbolt the oil pan.

- Unfasten and remove the oil pump and pickup tube.

- Remove the Piston and Connecting Rod Assemblies:

- Turn the crankshaft to bottom dead center (BDC) for each piston.

- Unbolt connecting rod caps and carefully push pistons out from the top.

- Check Pistons and Cylinder Liners:

- Inspect pistons for scoring, cracks, or excessive wear.

- Check cylinder liners for pitting, wear marks, or overheating damage.

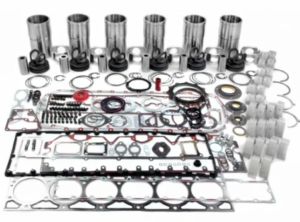

Piston Kit & Related Components for Cummins ISM engine

Piston Kit & Related Components for Cummins QSM11 engine

Step 5: Crankshaft and Main Bearing Disassembly

The crankshaft is one of the heaviest and most critical components in the engine.

- Remove the Crankshaft Bolts and Rear Main Seal:

- Loosen main bearing bolts in sequential order to prevent crankshaft distortion.

- Remove the rear main seal carefully to avoid damaging the crankshaft journal.

- Lift Out the Crankshaft:

- Support the crankshaft with a hoist or additional hands to prevent damage.

- Support the crankshaft with a hoist or additional hands to prevent damage.

- Inspect Bearings and Journals:

- Check bearings for excessive wear, scoring, or misalignment.

- Check bearings for excessive wear, scoring, or misalignment.

Crankshaft & Related Components for Cummins ISM engine

Crankshaft & Related Components for Cummins QSM11 engine

Proper Storage and Cleaning of Components

After disassembling the Cummins ISM, ISMe, or QSM11 engine, it is crucial to store components properly to prevent contamination and damage.

✔ Organize fasteners and small parts in labeled containers for easy reassembly.

✔ Use plastic covers to protect machined surfaces from dust and debris.

✔ Clean all metal components thoroughly using solvent, steam cleaning, or ultrasonic cleaners.

✔ Lubricate crankshaft journals, camshaft bearings, and pistons with engine oil to prevent rust.

Final Notes on Cummins ISM, ISMe, and QSM11 Engine Disassembly

✔ Follow a structured approach to prevent damage and misplacement of parts.

✔ Use proper lifting techniques and support heavy components with an engine stand or hoist.

✔ Label and store all fasteners, bolts, and small components correctly for smooth reassembly.

✔ Inspect components for excessive wear, cracks, or warping before reassembly.

✔ Consult an OEM manual or Diesel Pro Power for reassembly torque values and procedures.

By following these best practices for disassembly, you can ensure a successful engine rebuild or repair, minimizing downtime and optimizing the performance of your Cummins ISM, ISMe, and QSM11 engine.

Parts Catalog for ISM Cummins Marine and Industrial Engines

Parts Catalog for QSM11 Cummins Marine and Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588