Cummins QSM Parts - Crankshaft Section

Loading...

Loading... Cummins QSM11 Crankshaft Components & Rebuild Solutions

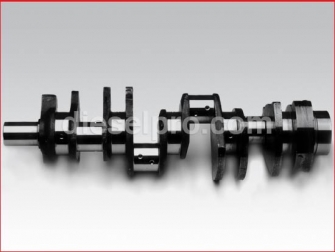

The crankshaft is the heart of the Cummins QSM11 engine’s bottom end. It transforms linear piston motion into the rotary power that drives marine propellers, industrial pumps, compressors, and generator sets. Subjected to continuous torsional forces, combustion shock, and high RPM stress, the crankshaft must remain perfectly balanced, aligned, and supported to preserve engine performance and longevity.

At Diesel Pro Power, we provide new crankshafts, precision-matched bearing shell sets, rear and front crank seals, and gasket kits engineered specifically for the Cummins QSM11. Whether you're rebuilding an engine in a commercial vessel or maintaining a standby generator, our inventory includes all the parts you need to restore full crankshaft reliability.

New Crankshaft for Cummins QSM11

Premium OEM-Spec Crankshaft

We supply brand-new crankshafts manufactured to Cummins OEM specifications. Each crankshaft undergoes rigorous inspection and finishing processes to ensure:

-

Exact Journal Dimensions: For proper bearing fit and oil film formation

-

Balanced Rotational Mass: To prevent vibration and bearing stress

-

Hardened Surfaces: On rod and main journals for long service life

-

Gear Drive Compatibility: With QSM11 front timing assemblies

This crankshaft is a direct-fit solution for QSM11 marine and industrial engines. It is ready to install with no need for regrinding or modification, making it ideal for time-sensitive overhauls where downtime must be minimized.

Crankshaft Bearing Shell Sets

Standard Size Crankshaft Bearings

The standard bearing shell set includes upper and lower halves for all main bearing journals. These shells:

-

Maintain the oil clearance needed for proper lubrication

-

Provide low-friction support for crankshaft rotation

-

Embed microscopic debris to prevent crankshaft scoring

Standard-size bearings are used when the crankshaft journals mic within original factory specifications. They are recommended for engines being rebuilt with minimal crankshaft wear.

Oversize Crankshaft Bearings (0.010”)

Oversize bearing shell sets are used when the crankshaft has been machined or polished due to scoring, taper, or journal wear. The 0.010” oversize version:

-

Provides increased thickness to accommodate undercut journals

-

Restores oil clearance to Cummins specifications

-

Allows continued use of an otherwise salvageable crankshaft

These bearings are commonly used in high-hour engines that have undergone at least one previous overhaul. Proper machining and journal inspection are essential before installation.

Rear Crankshaft Seal Kit

The rear main seal is a critical oil barrier located at the rear of the crankshaft where it exits the engine block to mate with the flywheel or transmission.

Key Features:

-

Double-lip sealing surface to retain oil at high RPM

-

Optional installation sleeve for later-model QSM11 engines

-

High-temperature elastomer to resist breakdown under load and heat

A failed rear crank seal can lead to:

-

Oil leakage at the flywheel housing

-

Premature clutch or transmission damage (in certain applications)

-

Contaminated engine compartments in marine engines

Always replace the rear seal during an engine rebuild or crankshaft replacement. Doing so protects the investment and ensures long-term oil control.

Front Cover Seal Ring

The front crankshaft seal ring sits at the gear housing and seals the crankshaft nose where it drives the camshaft and accessory gears.

-

Prevents oil leakage at the front cover

-

Maintains crankcase pressure integrity

-

Reduces risk of contaminating the gear train

Replacing the front seal is standard practice during any crankshaft or timing gear service. Given the rotational demands of the QSM11 front gear system, even minor seal wear can lead to leaks or long-term component degradation.

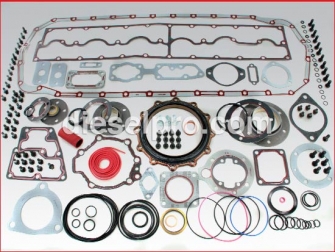

Lower Gasket Set

The lower gasket set includes the crankshaft-related gaskets needed during bottom-end service or full engine overhaul. This typically includes:

-

Oil pan gasket

-

Rear and front main seals

-

Gear housing seals

-

Inspection port gaskets

-

Accessory drive cover gaskets

These components are essential to reseal the engine after the crankshaft is removed or replaced. They help ensure that oil retention, pressure control, and vibration damping are restored to factory levels.

Crankshaft Rebuild Best Practices for Cummins QSM11

When to Replace or Recondition the Crankshaft

Crankshaft replacement or machining is typically required when:

-

Main or rod journal surfaces show scoring or discoloration

-

Journal taper or out-of-round exceeds manufacturer tolerances

-

Engine has experienced bearing failure or oil starvation

-

Vibration or imbalance is detected during operation

If your crankshaft journals mic within spec and show minimal wear, standard-size bearings may be used. If the journals are damaged, regrinding to an undersize is acceptable—as long as appropriate oversize bearings are installed.

Measuring Crankshaft Journal Wear

Always use a calibrated micrometer to measure:

-

Journal diameter

-

Taper across width

-

Out-of-round deviation

For Cummins QSM11, bearing clearances must meet tight tolerances to avoid:

-

Oil pressure loss

-

Vibration

-

Excess bearing wear

-

Engine knock or crankshaft fatigue

If you are unsure whether to reuse your existing crankshaft, Diesel Pro Power can assist you in selecting the appropriate size bearing set or complete replacement crank.

Preventing Crankshaft Damage

To protect the crankshaft and ensure long-term performance:

-

Use high-quality oil and change it at recommended intervals

-

Maintain proper oil pressure with a functioning oil pump

-

Inspect and replace main and rod bearings during each overhaul

-

Replace front and rear seals any time the crankshaft is serviced

-

Balance the crankshaft and rotating assembly if new components are installed

Common Symptoms of Crankshaft-Related Issues

-

Low oil pressure at idle or under load

-

Knocking sound deep in the engine, particularly under acceleration

-

Metal shavings in oil pan or filter

-

Oil leakage at front or rear seal

-

Excessive engine vibration or flywheel misalignment

If any of these symptoms are present, it’s essential to inspect the crankshaft and bearings immediately. Continued operation can result in a thrown rod, spun bearing, or complete engine failure.

Other Components Often Replaced With the Crankshaft

During bottom-end service or crankshaft replacement, it's recommended to also inspect or replace:

-

Connecting rods and bearings

-

Oil pump

-

Main bearing caps and fasteners

-

Crankshaft damper or pulley

-

Lower main seals and gaskets

-

Oil cooler and cooler seals

This approach minimizes the risk of future downtime and ensures the QSM11 engine operates at peak mechanical efficiency.

Why Choose Diesel Pro Power for Crankshaft Components?

-

Over 40,000 Customers Worldwide

-

Dedicated Expertise in QSM11 Applications

-

OEM-Quality Components Backed by Technical Support

-

Same-Day Shipping Available on Most Items

-

Spanish-Speaking Assistance (Hablamos Español)

We stock what you need, ship fast, and stand behind every crankshaft, bearing, and seal kit we sell.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588