Introduction

When your Cummins C Series engine—including the 6C, 6CT, and 6CTA—begins showing signs of wear, reduced power output, rising oil consumption, or recurring mechanical issues, it may be time to consider a complete engine overhaul. An overhaul goes beyond basic repairs by renewing critical internal components, restoring proper clearances, compression, and combustion efficiency. This process can return the engine to near-original performance while significantly extending its service life and reliability, especially in demanding marine, industrial, or commercial applications.

Choosing a Diesel Pro Power aftermarket overhaul kit ensures you receive high-quality, precision-engineered components designed to meet or exceed OEM specifications. These kits are built for durability under continuous-duty operation and harsh conditions, helping reduce future downtime. In addition, Diesel Pro Power overhaul kits often provide a more cost-effective solution than OEM alternatives, delivering long-term value without sacrificing performance or dependability.

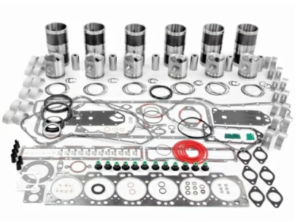

Overhaul Kit & Related Components for Cummins 6C Marine & Industrial Engines

Overhaul Kit & Related Components for Cummins 6CT Marine & Industrial Engines

Overhaul Kit & Related Components for Cummins 6CTA Marine & Industrial Engines

This guide covers:

- Deciding Between a Rebuild and Replacement

- Key Steps in Overhauling a Cummins C Series Engine

- Post-Overhaul Testing and Inspection

1. Deciding Between a Rebuild and Replacement

A. When to Choose an Overhaul (Rebuild)

An engine overhaul is the ideal solution when major wear is present but the engine block and core components remain structurally sound. It is especially appropriate when compression is low, yet inspections confirm the block, crankshaft, and main castings are still serviceable. In these cases, an overhaul can restore proper cylinder sealing and combustion efficiency without the expense of replacing the entire engine.

Overhauls are also recommended when there are clear signs of internal wear, such as rising oil consumption, declining fuel economy, hard starting, or loss of power under load. Excessive exhaust smoke—whether blue, black, or white—often points to worn piston rings, valve guides, or sealing surfaces that can be corrected during a rebuild. For many operators, an overhaul provides the opportunity to restore performance, reliability, and service life at a fraction of the cost of a full engine replacement.

Using Diesel Pro Power aftermarket overhaul kits ensures you receive premium-grade components, including pistons, piston rings, bearings, gaskets, and seals. Each component is precision-manufactured to meet or exceed OEM specifications, delivering dependable performance, proper fitment, and long-term durability in demanding marine, industrial, and commercial applications.

B. When to Consider Engine Replacement

Replacement may be the better option when engine damage goes beyond normal wear and repair limits. If the engine block or cylinder head has cracks, severe corrosion, or structural damage, rebuilding may no longer be reliable or cost-effective, as these components are critical to maintaining compression and long-term durability. Likewise, catastrophic failures such as a thrown connecting rod, spun main bearings, or extensive crankshaft damage can compromise the integrity of the entire engine, making replacement the safer choice.

Replacement is also worth considering when labor costs, machining, and parts required for an overhaul exceed the price of a new or remanufactured engine. In these cases, installing a replacement engine can reduce downtime, simplify logistics, and provide warranty-backed peace of mind.

That said, many engines initially assumed to be “beyond repair” can often be economically restored with a thorough inspection and a high-quality Diesel Pro Power overhaul kit. Issues like worn cylinders, tired bearings, or declining compression are frequently resolved during a rebuild, allowing operators to extend engine life significantly while avoiding the high upfront cost of full replacement.

2. Key Steps in Overhauling a Cummins C Series Engine

A. Preparation

Gather Tools and Parts:

Begin by sourcing a Diesel Pro Power overhaul kit engineered specifically for your Cummins 6C, 6CT, or 6CTA engine. Using a model-correct kit ensures proper fitment, correct clearances, and long-term reliability after the rebuild. In addition to the overhaul kit, assemble all required tools before disassembly to avoid delays. Essential tools include a calibrated torque wrench for accurate fastener tightening, micrometers and dial bore gauges for measuring wear, an engine hoist or stand for safe handling, seal and liner installation tools, and high-quality cleaning equipment such as parts washers, brushes, and lint-free cloths.

Prepare the Work Area:

A clean, well-organized workspace is critical to a successful engine overhaul. Dirt, debris, or metal particles can quickly damage new components. Ensure the area is well lit, free of dust, and has ample bench space for laying out parts in order. Label components during removal, keep fasteners grouped by location, and cover exposed engine surfaces to prevent contamination throughout the rebuild process.

B. Engine Disassembly

Drain Fluids

Begin the overhaul by completely draining all engine fluids. Remove the engine oil and dispose of it properly, then drain the coolant from the radiator, block, and any auxiliary cooling components. Fully draining these fluids prevents spills during disassembly and reduces the risk of contamination inside the engine. Take this opportunity to inspect drained fluids for metal particles, coolant contamination, or sludge, as these can provide early clues about internal wear or failure points.

Remove External Components

Carefully detach all external components, including the turbocharger, intake and exhaust manifolds, fuel lines, injectors, sensors, and electrical wiring harnesses. Label hoses, connectors, and fittings to ensure correct reinstallation later. Removing these components methodically prevents damage and simplifies access to the core engine assemblies.

Cylinder Head Removal

Unbolt the cylinder head following the proper loosening sequence to avoid warping. Use appropriate lifting equipment to carefully raise and remove the head, then inspect it for cracks, valve wear, or gasket failure.

Piston and Crankshaft Disassembly

Remove the oil pan to access the bottom end. Extract the pistons, connecting rods, and crankshaft, keeping components organized and marked for inspection or replacement during the rebuild.

C. Cleaning and Inspection

Clean Components

Thoroughly clean all reusable engine components before inspection and reassembly. Use a solvent tank, parts washer, or approved degreasing solution along with stiff and soft brushes to remove oil residue, carbon buildup, gasket material, and debris. Pay special attention to oil passages, coolant passages, and threaded holes, as trapped contaminants can cause premature failure after the rebuild. Once cleaned, dry all components completely and protect machined surfaces with a light coat of clean engine oil to prevent corrosion.

Inspect for Damage

Carefully inspect each component for signs of wear, fatigue, or damage. Examine the cylinder walls for scoring, glazing, or taper that could affect ring sealing. Inspect crankshaft journals for scratches, discoloration from heat, or out-of-round wear. Use micrometers, bore gauges, and plastigage as needed to measure critical dimensions and confirm they are within Cummins service limits. Check connecting rods, pistons, and bearings for cracks or abnormal wear patterns.

If any components are worn beyond repair, Diesel Pro Power overhaul kits include high-quality replacement pistons, bearings, seals, and gaskets to restore the engine to reliable operating condition.

D. Reassembly with Diesel Pro Power Overhaul Kits

Install New Components

Begin reassembly by installing the new pistons, liners, piston rings, bearings, seals, and gaskets included in your Diesel Pro Power overhaul kit. Each component is engineered for precise fitment with Cummins 6C, 6CT, and 6CTA engines, helping ensure proper clearances and long-term reliability. Use proper installation tools for liners, rings, and seals to prevent damage during assembly, and lubricate all moving parts with clean engine oil or approved assembly lube.

Torque Specifications

Strictly follow Cummins factory torque specifications for all fasteners, including main bearing caps, connecting rods, cylinder head bolts, and ancillary components. Correct torque sequencing and values are critical to prevent distortion, leaks, and premature component failure. Always use a calibrated torque wrench and follow the recommended tightening patterns.

Gasket Installation

Before installing new gaskets, ensure all mating surfaces are clean, flat, and free of oil or debris. Proper surface preparation ensures correct sealing and prevents coolant, oil, or compression leaks after startup.

Timing and Valve Adjustment

Set injection timing and valve lash precisely according to Cummins specifications. Accurate timing and valve adjustment are essential for proper combustion, fuel efficiency, and smooth engine operation.

Using Diesel Pro Power overhaul kits ensures component compatibility and consistency, significantly reducing the risk of post-overhaul issues and extending engine service life.

3. Post-Overhaul Testing and Inspection

A. Initial Testing

Pre-Lube the Engine

Before the initial startup, it is critical to pre-lubricate the engine to prevent a dry start, which can cause immediate bearing and camshaft damage. Prime the oil system by spinning the oil pump or cranking the engine with the fuel system disabled until proper oil pressure is achieved. This step ensures that oil is fully circulated to all bearings, journals, and internal components before combustion begins.

Initial Start

Once pre-lubed, perform the first engine start while closely monitoring oil pressure, coolant temperature, and engine RPM. Oil pressure should build almost immediately. Allow the engine to idle at a moderate speed while listening carefully for abnormal noises such as knocking, ticking, or grinding that could indicate improper assembly or clearance issues. Avoid high RPMs during this initial run-in period.

Leak Check

As the engine warms up, thoroughly inspect all gasketed surfaces, seals, hoses, and fittings for signs of oil, coolant, or fuel leaks. Pay close attention to the oil pan, cylinder head gasket area, fuel lines, and coolant connections. Addressing leaks immediately helps prevent contamination, overheating, and potential damage during the break-in process.

B. Break-In Procedure

Follow a proper break-in process to ensure piston rings seat correctly against the cylinder walls and bearings establish proper wear patterns. During the initial hours of operation, run the engine at varying RPMs rather than holding a constant speed. This helps promote even ring seating, proper oil distribution, and stable combustion across all cylinders. Avoid heavy loads or full-throttle operation during the early break-in period, as excessive cylinder pressure can damage new components before they have had time to seat properly.

Avoid prolonged idling, especially during the first several hours of operation. Extended idling can prevent rings from seating correctly, lead to cylinder glazing, and reduce overall engine efficiency. Instead, operate the engine under light to moderate load while gradually varying engine speed. Monitor oil pressure, coolant temperature, and exhaust conditions throughout the break-in process, and perform an initial oil and filter change after the recommended break-in interval to remove any residual assembly debris.

C. Post-Overhaul Inspection

Recheck Bolt Torques

After the first 10–20 hours of operation, recheck critical fasteners such as cylinder head bolts, exhaust manifold bolts, and accessory mounting hardware. Heat cycles during early operation can cause components to settle, and verifying proper torque helps prevent leaks, gasket failures, and long-term reliability issues.

Oil and Filter Change

Replace the engine oil and oil filter after the first 50 hours of operation to remove metal particles, assembly residue, and contaminants created as new components wear in. Using fresh oil at this stage protects bearings, pistons, and cylinder walls, and establishes a clean lubrication baseline for continued service.

Performance Monitoring

During the early operating period, closely monitor fuel efficiency, exhaust smoke color, oil consumption, and overall engine response. Any changes in starting behavior, power output, or operating temperature should be addressed promptly to prevent further issues.

Using Diesel Pro Power aftermarket overhaul kits provides more than just replacement parts—it delivers confidence. Each kit is built to meet or exceed OEM specifications, offering enhanced durability, precise fitment, and dependable performance. Designed for efficient installation, Diesel Pro Power kits help minimize downtime and ensure your Cummins C Series engine returns to reliable, like-new operation.

Conclusion

An engine overhaul is a significant investment of both time and resources, but when done correctly it represents a smart, long-term strategy for protecting your equipment. With a careful rebuild and high-quality components from Diesel Pro Power, an overhaul becomes an opportunity to extend engine service life, restore lost horsepower, improve fuel efficiency, and enhance overall reliability. Replacing worn internal components allows the engine to return to near-original operating condition, often delivering performance comparable to a new engine at a fraction of the cost.

In many cases, choosing an overhaul over full engine replacement is the most cost-effective solution—especially when the engine block and major castings remain structurally sound. Diesel Pro Power aftermarket overhaul kits are engineered to meet or exceed OEM specifications, ensuring proper fitment, durability, and long-term performance. These kits simplify the rebuild process by providing all critical components in one package, reducing downtime and installation errors. For Cummins engine owners focused on maximizing value, uptime, and reliability, a properly executed overhaul with Diesel Pro Power components is a proven path to dependable performance.

Overhaul Kit & Related Components for Cummins 6C Marine & Industrial Engines

Overhaul Kit & Related Components for Cummins 6CT Marine & Industrial Engines

Overhaul Kit & Related Components for Cummins 6CTA Marine & Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588