Cummins 6C Engine Parts - Rebuild Kit Section

Loading...

Loading... -

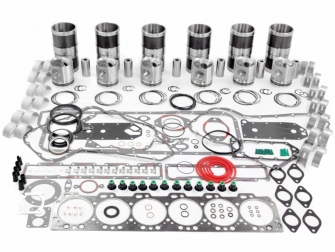

Cummins Rebuild Kit for 6C, 6CT, 6CTA - 1 piece piston

IFK2397-6C

For engines with CPL #s 602, 603, 753, 819, 828, 829, 942, 955, 985, 1248, 1274, 1275, 1281, 1356, 1464, 1603, 1616, 1661, 1988, 2035, 2161, 2162, 2182, 2183, 2284, 2285, 2343, 2344, 2406, 2407, 2408, 2409, 2410, 2411, 2413, 2544, 2545, 2620

Price: $ 1,384.73 -

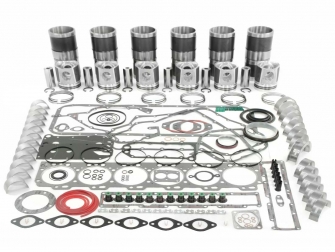

Cummins Rebuild Kit for 6C, 6CT, 6CTA - 1 piece piston

IFK2398-6C

For engines with CPL #s 604, 605, 754, 755, 830, 831, 890, 892, 893, 959, 982, 984, 1212, 1222, 1269, 1270, 1273, 1321, 1377, 1419, 1539, 1547, 1604, 1612, 1633, 1639, 1804, 1826, 1903, 2058, 2380, 8930

Price: $ 1,439.68 -

Cummins Rebuild kit 6C, 6CT, 6CTA - 1 piece piston

IFK0059-6C

For engines with CPL #s 1216, 1217, 1221, 1282, 1366, 2172, 2960, 8089

Price: $ 1,811.94 -

Cummins Rebuild Kit 6C, 6CT, 6CTA - 1 piece piston

IFK2657-6C

For engines with CPL #s 1845, 1846, 1943, 2007, 2054, 2055, 2056, 2057, 2060, 2061, 2062, 2082, 2118, 2120, 2185, 2216, 2217, 2218, 2219, 2250, 2549, 2556, 2642, 2833, 2873, 2874, 2894, 2951, 3332, 8000, 8222, 8289, 8290, 8388, 8509, 8759

Price: $ 1,621.62 -

Cummins Rebuild Kit for 6C, 6CT, 6CTA - 1 piece piston

IFK0318-6CTA

For engines with CPL #s 2241 ,2299, 2964, 8578

Price: $ 1,679.62 -

Nozzle to cool pistons Cummins 6C, 6CT, ISC, QSC, L10, ISL, QSL

3928031

Size 1.22" long. Engine requires 6 per engine, for articulated pistons

Price: $ 0.90 -

Nozzle to cool pistons for Cummins 6C, ISC, QSC, L, ISL, QSL

3905928

Size 1.73". 6 per engine required

Price: $ 1.48 -

-

Cummins Crankshaft Seal Kit - Front

3925343

Includes the seal and sleeve, for non-automotive applicationsPrice: $ 46.52 -

-

Cummins Crankshaft Seal Kit - Rear

4955372

Includes the seal (double lip) and sleeve, for engines with wet clutch housingPrice: $ 37.77 -

-

-

-

-

Cummins Fuel Filter

3890017

3.7" diameter, 5.46" height, thread: + 13/16- 18" - 14 UNF-28Price: $ 32.59 -

-

-

Cummins Fuel Filter & Water Separator

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INTPrice: $ 44.78 -

-

-

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

Cummins 6C Engine Rebuild Kits and Components Catalog

The Cummins 6C engine platform—including the 6C, 6CT, and 6CTA variants—is a cornerstone of mid-range diesel performance. Found in applications ranging from marine propulsion to heavy equipment and industrial generators, the 6C8.3L engine is known for its reliability, power density, and long service life.

When the time comes to overhaul your Cummins 6C engine, choosing the right rebuild kit is critical to regaining compression, restoring oil control, and ensuring long-term performance. At Diesel Pro, we carry complete in-frame overhaul kits and essential support components for nearly every major CPL (Control Parts List) configuration of the 6C, 6CT, and 6CTA engines.

Complete Overhaul Kits for Cummins 6C by CPL

Each rebuild kit includes:

-

One-piece pistons

-

Piston rings

-

Cylinder liners

-

Rod bearings

-

Main bearings

-

Thrust washers

-

Full gasket set (upper and lower)

-

Optional seals, depending on CPL and configuration

All components are designed to meet or exceed OEM specifications. Kits are matched to specific CPLs to ensure exact fitment across combustion chambers, liner bore sizes, and piston types.

Overhaul Kit for Cummins 6C / 6CT / 6CTA – CPLs:

602, 603, 753, 819, 828, 829, 942, 955, 985, 1248, 1274, 1275, 1281, 1356, 1464, 1603, 1616, 1661, 1988, 2035, 2161, 2162, 2182, 2183, 2284, 2285, 2343, 2344, 2406, 2407, 2408, 2409, 2410, 2411, 2413, 2544, 2545, 2620

This overhaul kit is compatible with some of the most widely used variants of the 6CTA platform, common in industrial pumps, stationary power units, and off-road vehicles. One-piece pistons included in this kit offer superior structural strength compared to articulated designs.

Compression Ratio: 17.0:1

Explanation: This standard diesel compression ratio is engineered for consistent combustion, even under heavy load. It strikes a balance between power, fuel economy, and cold-start reliability.

Overhaul Kit for Cummins 6C / 6CT / 6CTA – CPLs:

604, 605, 754, 755, 830, 831, 890, 892, 893, 959, 982, 984, 1212, 1222, 1269, 1270, 1273, 1321, 1377, 1419, 1539, 1547, 1604, 1612, 1633, 1639, 1804, 1826, 1903, 2058, 2380, 8930

Designed for variants that see diverse applications—from agriculture to transit—this kit includes the same forged, one-piece pistons and hardened steel rings for extended durability in variable duty cycles.

Compression Ratio: 16.5–17.0:1

Explanation: Lower compression ratios are often selected for engines with higher turbo boost levels or tighter emissions requirements. These ratios help reduce peak cylinder pressure and temperature, which enhances turbo life and reduces NOx formation.

Overhaul Kit for Cummins 6C / 6CT / 6CTA – CPLs:

1216, 1217, 1221, 1282, 1366, 2172, 2960, 8089

This kit supports a specialized group of high-load industrial engines used in material handling, forestry equipment, and power generation. Piston crowns are anodized for heat resistance in applications with extended run times.

Compression Ratio: 17.3:1

Explanation: A slightly higher compression ratio boosts torque and aids cold starting, especially useful in colder climates or when engines operate at low RPM under continuous load.

Overhaul Kit for Cummins 6C / 6CT / 6CTA – CPLs:

1845, 1846, 1943, 2007, 2054, 2055, 2056, 2057, 2060, 2061, 2062, 2082, 2118, 2120, 2185, 2216, 2217, 2218, 2219, 2250, 2549, 2556, 2642, 2833, 2873, 2874, 2894, 2951, 3332, 8000, 8222, 8289, 8290, 8388, 8509, 8759

Engineered for a wide range of industrial and marine setups, this kit includes hardened steel top rings for enhanced wear resistance under high-combustion conditions.

Compression Ratio: 17.5:1

Explanation: This high compression supports optimal atomization and combustion efficiency, ideal for engines that are not EGR-equipped or use traditional fuel mapping.

Overhaul Kit for Cummins 6C / 6CT / 6CTA – CPLs:

2241, 2299, 2964, 8578

This kit fits the newest generation of 6CTA variants, many of which serve as genset power units and marine propulsion systems. Its matched gaskets and bearings are designed for long-run-hour intervals.

Compression Ratio: 17.5:1

Explanation: A high compression ratio increases combustion speed and thermal efficiency, ensuring strong performance in high-load, steady-state applications such as continuous-duty generators.

Related Components and Tools for Cummins 6C Rebuilds

In addition to overhaul kits, Diesel Pro offers all the necessary supporting components to complete your rebuild right the first time.

Piston Cooling Nozzles

Oil nozzles are vital to prevent piston overheating during combustion. We offer two sizes for the Cummins 6C platform:

-

1.22" long nozzles – For articulated piston setups

-

1.73" long nozzles – For longer stroke or one-piece piston configurations

Each engine requires six piston cooling nozzles.

Crankshaft Seal Kits

Available with integrated sleeves and dust shields to ensure leak-free operation during crank rotation. Choose between standard and non-automotive configurations depending on CPL.

Offered for both dry and wet clutch housing engines. Always replace rear main seals during rebuilds to avoid crankcase leaks post-installation.

Expansion Plug Kits

The expansion plug kit (also known as the freeze plug kit) includes all necessary press-fit plugs for the coolant passages in your 6C block. Replacing these during a rebuild helps avoid pressure leaks or cooling system failures down the line.

Fuel Filters & Water Separators

Restore clean fuel delivery with high-quality spin-on filters compatible with 6C8.3, 6CT, ISC, and QSC engines. Options include:

-

Standard spin-on filters

-

Large capacity filters

-

Fuel-water separators with integrated drain valves

Essential Tools for a Successful Rebuild

-

Feeler Gauge Set: .002” to .025” range to properly set valve lash on reassembled heads.

-

Piston Ring Installation Tool: Ensures safe, uniform ring placement during piston assembly.

-

Fuel & Oil Filter Removal Wrenches: Avoid damaging filter housing threads during service.

Additional Components for Long-Term Performance

-

Turbo Mounting Gaskets: For water-cooled turbo configurations

-

Exhaust Outlet Gaskets: Ensures tight sealing at the manifold flange

-

Vibration Isolators: Available in 4-piece sets for block-to-frame mounting

-

Temperature Switches: Compatible with Cummins, Detroit Diesel, and Caterpillar systems

-

Mechanical and Electrical Gauges: Available in 12V and 24V for monitoring oil pressure, coolant temp, and engine RPM

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588