Ensuring engine safety is paramount when working on Detroit Diesel 149 Series engines. These powerful, heavy-duty engines have large, complex components and electrical systems that require specific precautions to protect both the operator and the equipment. Key areas of focus include disconnecting the battery to prevent accidental starting and following proper lifting techniques to handle heavy components safely.

Proper Lifting Techniques: Securing Heavy Components Correctly

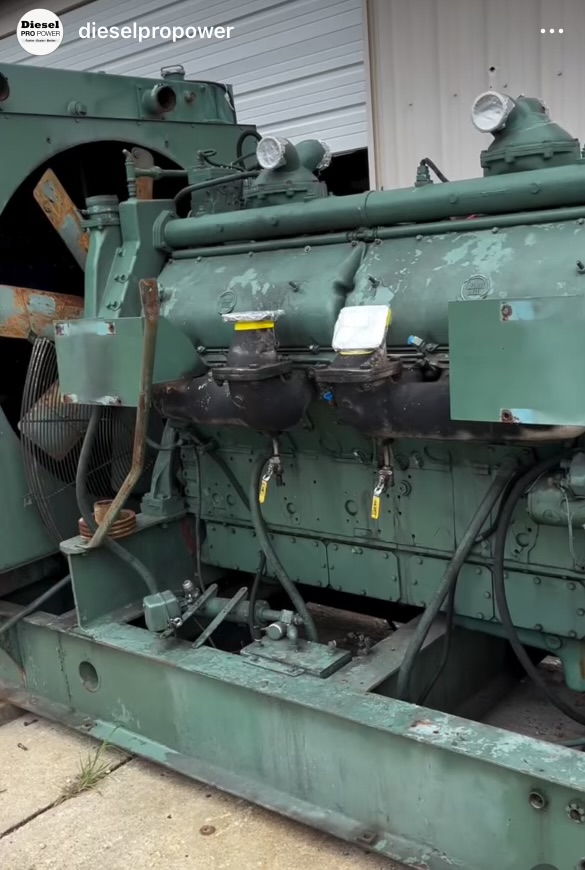

The Detroit Diesel 149 Series engines consist of large, heavy components designed to deliver exceptional power and durability. However, their weight and size make handling and moving these parts inherently risky without the right equipment and techniques. Proper lifting practices are essential for protecting technicians, avoiding workplace injuries, and ensuring the integrity of the components being serviced.

1. Using Engine Lifter Brackets as Recommended

Detroit Diesel designed the 149 Series engines with designated lifting brackets and attachment points to facilitate safe and secure handling of heavy components.

- Why Use Recommended Brackets?

- Engineered for Safety:

These brackets are designed to bear the engine’s weight, ensuring stability during lifting.

- Preventing Damage:

Non-designated lifting points can deform or crack under stress, potentially causing structural damage to the engine or failure during the lift.

- Minimizing Risk:

Improper lifting points increase the chance of components slipping, which could lead to severe injuries or damage to surrounding equipment.

- Engineered for Safety:

- Best Practices:

- Inspect lifting brackets for wear, cracks, or corrosion before use.

- Ensure bolts and attachments are securely fastened to the brackets.

- Follow Detroit Diesel’s manual for specific guidance on attaching lifting equipment to the designated points.

2. Choosing the Right Lifting Equipment

Heavy components like cylinder heads, blocks, or turbochargers require specialized lifting tools capable of supporting substantial weight.

- Essential Tools for Lifting:

- Cranes and Hoists:

Ideal for lifting entire engine assemblies or larger parts.

- Hydraulic Jacks:

Useful for precise adjustments when removing or installing heavy components.

- Slings and Chains:

Ensure these are rated for loads exceeding the weight of the components being handled.

- Cranes and Hoists:

- Inspection and Setup:

-

Check all equipment for signs of wear, damage, or defects before use.

- Ensure lifting devices are positioned to maintain balance and stability during the lift.

- Use spreader bars for wide or irregularly shaped parts to evenly distribute weight and reduce stress on lifting points.

-

3. Securing Components Before Lifting

Stabilizing heavy components before and during lifting is critical to preventing accidents.

- Pre-Lift Checks:

- Ensure that the component is free of loose or dangling parts that could shift unexpectedly.

- Verify that all bolts or fasteners securing the part to its mounting location are fully removed.

- For irregularly shaped items, use rigging techniques or additional supports to maintain stability.

- Balance and Alignment:

- Position lifting hooks or chains evenly around the component to distribute weight and avoid tilting.

- Slowly apply tension to the lifting device before fully lifting to ensure the load is balanced.

- Using Safety Accessories:

- Utilize load binders or ratchet straps to secure components during transport after lifting.

- Use blocking or cribbing to stabilize parts that need to be temporarily stored.

4. Avoiding Manual Lifting of Heavy Parts

While some smaller components may be suitable for manual handling, many parts in the Detroit Diesel 149 Series engines are far too heavy to lift without mechanical assistance.

- Risks of Manual Lifting:

- Strains and Sprains:

Attempting to lift heavy items manually can lead to musculoskeletal injuries, especially in the back, shoulders, or knees.

- Dropped Components:

Heavy parts can slip from a technician’s grasp, posing risks to personnel and the part itself.

- Strains and Sprains:

- Guidelines for Safe Handling:

- For smaller components, follow ergonomic lifting techniques: bend at the knees, keep the back straight, and lift using leg strength.

- Always assess the weight of the part before attempting to move it manually.

- For parts exceeding manual lifting limits, use mechanical aids such as dollies, hydraulic lifts, or team lifting procedures with adequate personnel.

5. Team Lifting for Medium-Weight Components

For components that fall into an intermediate weight range, team lifting can be an effective solution.

- Coordination and Communication:

- Ensure all team members understand the plan before lifting.

- Use clear signals or verbal commands to coordinate movements.

- Proper Technique:

- Distribute weight evenly among team members.

- Lift and lower in unison to prevent sudden shifts or imbalances.

6. Ensuring Workplace Safety

A well-organized and safe workspace is critical to executing proper lifting techniques.

- Clear the Area:

- Remove obstacles from the workspace to allow unobstructed movement of equipment and personnel.

- Ensure the floor is clean and free of oil, grease, or debris that could cause slips.

- Wear Appropriate Safety Gear:

- Use steel-toed boots, gloves, and protective eyewear to safeguard against accidents.

- For larger lifts, use hearing protection if noise levels exceed safety thresholds.

- Establish Safety Zones:

- Restrict access to the area around the lifting operation to prevent non-essential personnel from entering.

Conclusion

Proper lifting techniques are essential for maintaining safety and protecting the components of the Detroit Diesel 149 Series engines. By using the right equipment, following recommended procedures, and adhering to safety best practices, technicians can minimize risks while handling heavy parts. These precautions not only prevent injuries but also ensure the integrity and longevity of these powerful engines.

Conclusion Of Engine Safety For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

Following these engine safety practices—disconnecting the battery to prevent accidental starts and using proper lifting techniques for heavy components—ensures a safer working environment when maintaining or repairing Detroit Diesel 149 Series engines. These precautions help protect operators and equipment, reducing the risk of injury and ensuring that the engine remains in optimal condition throughout its service life.

Parts Catalog for 8V149 Detroit Diesel Marine Engine

Parts Catalog for 12V149 Detroit Diesel Marine Engine

Parts Catalog for 16V149 Detroit Diesel Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588