Engine Performance and Diagnostics

What are the signs of a failing fuel injector?

A failing fuel injector in Cummins ISB & QSB engines may cause rough idling, engine misfires, reduced fuel efficiency, and a noticeable loss of power. You might also notice increased exhaust emissions or black smoke due to improper fuel atomization. Unusual knocking sounds and difficulty starting the engine are also common symptoms. If you observe these signs, it’s crucial to have the injectors inspected and tested.

Parts Catalog Main Page for Cummins ISB Marine Engine

Cummins ISB 4.5 & Related Components

Cummins ISB 5.9 & Related components

Cummins ISB 6.7 & Related Components

Parts Catalog Main page for Cummins QSB Marine Engine

Cummins QSB 4.5 & Related Components

Cummins QSB 5.9 & Related Components

Cummins QSB 6.7 & Related Components

Cummins QSB 7.0 & Related Components

How often should I replace the oil filter?

The oil filter in Cummins ISB & QSB engines should generally be replaced every 15,000 miles or at every oil change interval, whichever comes first. However, severe duty applications may require more frequent changes. Regular oil filter replacement ensures optimal engine lubrication and helps prevent contaminants from damaging engine components.

Can I perform basic repairs without professional help?

Yes, basic repairs such as oil changes, filter replacements, and coolant checks can often be performed without professional assistance if you have basic mechanical knowledge and the proper tools. However, for complex issues like injector replacement, turbocharger repairs, or valve adjustments, it’s advisable to consult a qualified Cummins technician or refer to the OEM service manual for detailed guidance.

What should I do if my engine overheats?

If your Cummins ISB or QSB engine overheats, immediately stop the engine to prevent damage. Check the coolant level, radiator, and hoses for leaks or blockages. Ensure the radiator fan is functioning correctly. If coolant levels are adequate and the issue persists, have the thermostat, water pump, and cooling system inspected by a professional.

How do I identify my engine model and serial number?

The engine model and serial number are typically located on the engine dataplate, which is often found on the valve cover or the side of the engine block. The serial number is essential for ordering parts and obtaining service information. You can also find engine identification details in the ECM (Electronic Control Module) dataplate.

Exhaust and Fuel System

What causes excessive smoke from the exhaust?

Excessive smoke can be caused by various issues:

- Black smoke: Often due to excess fuel, poor air intake, or faulty injectors.

- White smoke: May indicate coolant leakage into the combustion chamber, often from a blown head gasket.

- Blue smoke: Usually a sign of oil burning, possibly from worn piston rings or valve seals.

Addressing these issues promptly helps prevent further engine damage.

How do I check for coolant leaks?

To check for coolant leaks:

- Inspect hoses, radiator, and connections for visible leaks.

- Look for coolant puddles under the vehicle.

- Perform a pressure test on the cooling system to identify hidden leaks.

- Check for white residue or coolant smell around engine components.

What are common turbocharger issues?

Common turbocharger issues include:

- Loss of power or poor acceleration

- Excessive exhaust smoke

- Unusual whining noises

- Oil leaks around the turbocharger

Regular inspection of the air intake system, turbo seals, and boost pressure levels helps maintain turbocharger performance.

How do I adjust valve clearances correctly?

Valve clearances should be adjusted following the engine-specific service manual. This involves:

- Rotating the engine to the correct position.

- Using a feeler gauge to measure the gap.

- Loosening the lock nut and adjusting the screw to achieve the correct clearance.

- Re-tightening the lock nut and rechecking the clearance.

Improper adjustments can lead to poor engine performance or damage.

Maintenance and Troubleshooting

What is the recommended oil change interval?

For Cummins ISB & QSB engines, the recommended oil change interval is typically every 15,000 miles or as specified by the engine duty cycle. Engines in severe-duty conditions may require more frequent changes. Always use high-quality oil that meets Cummins specifications.

How can I prevent engine overheating?

Prevent engine overheating by:

- Regularly checking coolant levels

- Ensuring the radiator and cooling system are clean

- Inspecting hoses and belts for wear

- Maintaining the thermostat and water pump

- Ensuring the radiator fan operates correctly

What should I do if my engine won’t start?

If your engine won’t start:

- Check the battery and connections.

- Ensure there’s sufficient fuel.

- Inspect the fuel filter and injection system.

- Check for fault codes using diagnostic tools.

- Verify the starter motor and solenoid are functioning.

How do I diagnose low oil pressure?

To diagnose low oil pressure:

- Check the oil level and condition

- Inspect the oil filter for clogs

- Test the oil pressure sensor

- Verify the oil pump operation

Low oil pressure can lead to severe engine damage, so address issues promptly.

Electrical System and Engine Components

How can I tell if my starter motor is failing?

Signs of a failing starter motor include a clicking sound when turning the key, the engine not cranking or cranking slowly, and intermittent starting issues. You might also notice smoke or a burning smell from the starter due to overheating. Testing the starter with a multimeter or performing a bench test can confirm its condition.

What causes engine vibrations?

Common causes of engine vibrations include worn engine mounts, unbalanced rotating components, misfiring cylinders, or issues with the drivetrain. Check for loose bolts, damaged pulleys, and imbalanced flywheels. Additionally, problems with the fuel system or ignition timing can also lead to noticeable vibrations.

How do I replace the water pump?

To replace the water pump on a Cummins ISB & QSB engine:

- Drain the coolant from the system.

- Remove the drive belts and any components blocking access.

- Unbolt and remove the old pump, noting the placement of gaskets.

- Install the new water pump with a fresh gasket, then torque bolts to specifications.

- Refill coolant and check for leaks after starting the engine.

What is the purpose of the EGR system?

The Exhaust Gas Recirculation (EGR) system reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the intake manifold. This process lowers combustion temperatures, improving emissions compliance. A properly functioning EGR system helps with fuel efficiency and reduces engine knocking.

How do I reset engine fault codes?

To reset engine fault codes:

- Use a diagnostic scan tool compatible with Cummins engines.

- Connect it to the OBD port and turn the ignition to the ON position (without starting the engine).

- Navigate to the “Clear Codes” option and follow the prompts to reset the codes.

- Restart the engine and check if the codes reappear.

If fault codes persist, it may indicate an underlying issue that needs further diagnosis.

Engine Issues and Cooling System

What causes coolant contamination in the oil?

Coolant contamination in the oil is often due to a blown head gasket, cracked engine block, or a failed oil cooler. This issue can cause the oil to appear milky or frothy and lead to engine overheating and poor lubrication. Addressing this problem quickly is crucial to prevent severe engine damage.

How do I check the turbocharger for damage?

To inspect the turbocharger:

- Remove the intake and exhaust pipes connected to the turbo.

- Check for excessive shaft play by gently moving the shaft up, down, and side to side.

- Look for oil leaks, cracked housings, or damaged compressor blades.

- Listen for whining or whistling noises during engine operation, which may indicate internal damage.

How do I inspect and clean the air filter?

To inspect and clean the air filter:

- Remove the air filter housing cover.

- Take out the air filter and inspect for dirt, debris, or oil contamination.

- If it’s reusable, use compressed air to blow debris from the inside out. For disposable filters, replace if dirty.

- Reinstall the filter and secure the housing properly.

What should I do if my engine loses power?

If your engine experiences a loss of power:

- Check for clogged fuel filters or fuel system issues.

- Inspect the turbocharger and air intake for blockages.

- Look for fault codes using a diagnostic tool to identify potential sensor failures or EGR issues.

- Ensure the fuel injectors and high-pressure fuel pump are functioning correctly.

How do I diagnose fuel injector problems?

To diagnose fuel injector issues:

- Listen for engine misfires or rough idling.

- Perform a balance test using diagnostic software to monitor cylinder performance.

- Check for fuel leaks around injector seals.

- Inspect the electrical connectors for damage and use a multimeter to verify injector pulse signals.

What is the proper coolant type for Cummins engines?

Cummins ISB & QSB engines require Heavy-Duty Extended Life Coolant (ELC) with Organic Acid Technology (OAT). This coolant provides superior corrosion protection and extends service intervals. Always ensure the coolant meets Cummins specifications, such as CES14603.

How do I bleed air from the fuel system?

To bleed air from the fuel system:

- Locate the manual priming pump (if equipped) or use a diagnostic tool to prime electronically.

- Loosen the bleed screw on the fuel filter housing.

- Pump until fuel flows without air bubbles, then tighten the screw.

- Attempt to start the engine; it may take several cranks to purge all air.

What causes black smoke from the exhaust?

Black smoke indicates excess fuel in the combustion process, often due to:

- Faulty fuel injectors

- Clogged air filters

- Turbocharger issues

- Incorrect fuel injection timing

- EGR system malfunctions

Proper diagnostics are needed to identify and correct the root cause.

How do I test the fuel pump for proper operation?

To test the fuel pump:

- Use a fuel pressure gauge to measure pressure at the fuel rail.

- Compare readings with manufacturer specifications.

- Listen for the pump’s operating sound when the ignition is turned on.

- Check the electrical supply to ensure proper voltage is reaching the pump.

What is the function of the crankshaft position sensor?

The crankshaft position sensor monitors the position and speed of the crankshaft, sending data to the ECM (Engine Control Module). This information helps control fuel injection timing and ignition timing. A faulty sensor can cause starting issues, misfires, and stalling.

Engine Components and Diagnostics

How do I replace the serpentine belt?

To replace the serpentine belt on a Cummins ISB & QSB engine:

- Locate the belt tensioner and use a wrench to relieve tension.

- Slide the old belt off the pulleys while noting the belt routing.

- Place the new belt around the pulleys following the correct path.

- Reapply tension with the tensioner and ensure the belt is seated properly on all pulleys.

How do I inspect the timing belt for wear?

To inspect the timing belt:

- Remove the timing cover to access the belt.

- Check for cracks, fraying, or glazing on the belt surface.

- Inspect for missing teeth or uneven wear.

- If the belt shows signs of wear, replace it immediately to prevent engine damage.

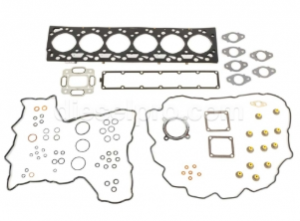

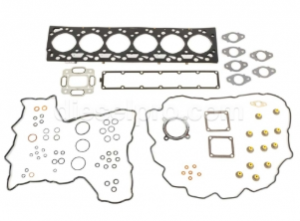

What are signs of a failing head gasket?

Common signs of a failing head gasket include:

- White smoke from the exhaust (coolant burning)

- Coolant loss without visible leaks

- Milky oil (coolant mixing with oil)

- Overheating and bubbling in the coolant reservoir

- Loss of engine power and rough idling

How do I maintain the battery and charging system?

To maintain the battery and charging system:

- Regularly check battery terminals for corrosion and ensure they are tight.

- Test the battery’s voltage with a multimeter (12.6V when off, 13.8-14.5V when running).

- Inspect the alternator belt for proper tension and wear.

- Ensure the alternator is charging the battery effectively.

What causes white smoke from the exhaust?

White smoke often indicates coolant entering the combustion chamber, which could be due to:

- A blown head gasket

- Cracked cylinder head or engine block

- Faulty EGR cooler (if equipped)

Persistent white smoke can cause severe engine damage if not addressed promptly.

How do I perform a compression test?

To perform a compression test:

- Warm up the engine slightly, then turn it off.

- Remove the glow plugs or injectors to access the cylinders.

- Insert the compression gauge into the cylinder.

- Crank the engine and record the reading.

- Compare the readings to manufacturer specifications. Low compression indicates potential valve, piston, or head gasket issues.

How do I diagnose electrical issues?

To diagnose electrical issues:

- Start by checking battery voltage and fuses.

- Inspect for loose connections, corroded terminals, or damaged wiring.

- Use a multimeter to test for continuity, voltage drops, and ground issues.

- If there are fault codes, use a diagnostic scanner to identify specific electrical problems.

What causes poor fuel economy?

Common causes of poor fuel economy in Cummins engines include:

- Clogged air filters restricting airflow

- Faulty fuel injectors causing inefficient combustion

- Incorrect tire pressure or dragging brakes (in vehicles)

- Dirty EGR valve or malfunctioning sensors (MAP, MAF, O2 sensors)

- Excessive idling or poor driving habits

How do I clean the EGR valve?

To clean the EGR valve:

- Remove the valve from the engine.

- Use an EGR valve cleaner or carburetor cleaner to dissolve carbon deposits.

- Gently scrub with a soft brush to avoid damaging the valve.

- Ensure the valve moves freely before reinstalling.

How do I replace glow plugs?

To replace glow plugs:

- Disconnect the battery to prevent electrical shorts.

- Remove the wiring harness connected to the glow plugs.

- Unscrew the old glow plugs with a deep socket.

- Install new glow plugs and torque them to manufacturer specifications.

- Reconnect the wiring harness and the battery.

Cooling System, Fuel System, and Engine Components

How do I test for coolant system leaks?

To test for coolant system leaks:

- Perform a visual inspection for any visible leaks around hoses, the radiator, and the water pump.

- Use a coolant pressure tester to pressurize the system and identify hidden leaks.

- Check for puddles under the vehicle and white residue around fittings, which may indicate dried coolant.

- Look for bubbles in the coolant reservoir while the engine is running, which may suggest a blown head gasket.

What causes high oil consumption?

High oil consumption can be caused by:

- Worn piston rings or valve seals, allowing oil to enter the combustion chamber.

- Turbocharger seal leaks, especially if oil is found in the intake or exhaust system.

- Oil leaks from gaskets, seals, or the oil pan.

- Running the engine with poor-quality oil or beyond recommended change intervals.

How do I identify a faulty MAP sensor?

A faulty Manifold Absolute Pressure (MAP) sensor may cause:

- Poor fuel economy and loss of power

- Rough idling and stalling

- Check engine light activation

To diagnose, use a diagnostic scanner to monitor live data. Test the sensor with a multimeter for proper voltage output as specified by the manufacturer.

How do I check and adjust the throttle position sensor?

To check and adjust the Throttle Position Sensor (TPS):

- Connect a diagnostic tool to read TPS voltage.

- The voltage should typically range from 0.5V (closed throttle) to around 4.5V (wide open throttle).

- If adjustment is needed, loosen the TPS mounting screws and rotate the sensor slightly to achieve the correct voltage.

- Retighten screws and verify the adjustment with the diagnostic tool.

What causes engine knocking sounds?

Engine knocking can result from:

- Pre-ignition or detonation due to low-quality fuel or incorrect ignition timing

- Worn rod bearings or piston slap

- Carbon buildup in the combustion chamber

- Faulty knock sensors failing to adjust timing properly

Addressing knocking sounds early can prevent serious engine damage.

How do I replace the fuel filter?

To replace the fuel filter:

- Relieve fuel system pressure by turning off the engine and disconnecting the battery.

- Locate the fuel filter, disconnect the fuel lines, and remove the old filter.

- Install the new filter, ensuring the flow direction arrow points correctly.

- Reconnect the fuel lines, prime the system (if necessary), and start the engine to check for leaks.

How do I test the camshaft position sensor?

To test the camshaft position sensor:

- Use a multimeter to check for proper voltage supply (usually around 5V).

- Measure the signal output while cranking the engine; the voltage should fluctuate if the sensor is functioning correctly.

- If no signal is detected, inspect the wiring harness and connector for damage.

- Replace the sensor if it fails the tests.

What is the purpose of the intercooler?

The intercooler cools the compressed air from the turbocharger before it enters the engine’s intake manifold. This process increases air density, leading to improved combustion efficiency, more power output, and lower exhaust temperatures. A properly functioning intercooler also helps reduce engine knock and boosts fuel economy.

How do I flush the cooling system?

To flush the cooling system:

- Drain the old coolant by opening the radiator drain valve.

- Fill the system with a coolant flush solution and distilled water.

- Run the engine until it reaches operating temperature, then turn it off and drain the solution.

- Rinse with clean distilled water until clear.

- Refill with fresh coolant and bleed the system of air pockets.

What are common issues with the fuel injection system?

Common fuel injection system issues include:

- Clogged fuel injectors causing poor spray patterns

- Faulty high-pressure fuel pumps leading to inconsistent fuel delivery

- Leaking injector seals causing loss of fuel pressure

- Electrical issues such as faulty wiring or injector driver modules

- Contaminated fuel affecting injector performance

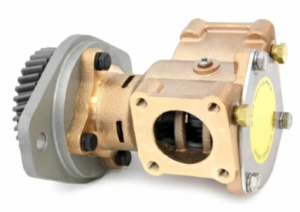

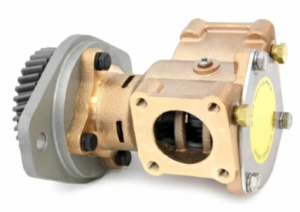

How do I replace the oil pump?

To replace the oil pump on a Cummins ISB & QSB engine:

- Drain the engine oil completely.

- Remove the oil pan to access the pump.

- Disconnect the oil pickup tube and unbolt the oil pump.

- Install the new oil pump, ensuring it is properly aligned.

- Reattach the oil pan, refill with oil, and check for leaks after starting the engine.

What causes engine surging?

Engine surging can result from:

- Vacuum leaks causing inconsistent air intake

- Faulty fuel injectors or fuel pressure regulator issues

- Dirty throttle body or malfunctioning EGR valve

- Problems with sensors such as the MAF, MAP, or TPS

Surging is often accompanied by fluctuating RPMs, especially at idle or under load.

How do I adjust the idle speed?

To adjust the idle speed:

- Connect a diagnostic tool to the ECM (Electronic Control Module).

- Access the idle speed settings within the software.

- Adjust to the recommended RPM range (usually 600-800 RPM for Cummins ISB & QSB).

- Save the settings and verify stability after adjustment.

How do I diagnose turbo lag issues?

To diagnose turbo lag:

- Check for boost leaks in the intercooler piping and connections.

- Inspect the wastegate actuator and vacuum lines for proper operation.

- Verify the turbocharger’s condition for signs of wear or damage.

- Ensure the air filter isn’t clogged, restricting airflow.

How do I inspect the exhaust manifold for leaks?

To inspect for exhaust manifold leaks:

- Visually check for cracks, carbon deposits, or burn marks around the manifold and gaskets.

- Listen for ticking sounds during engine operation, indicating escaping exhaust gases.

- Use a smoke machine to detect leaks or spray soapy water on the manifold while the engine runs and look for bubbles.

What causes engine misfires?

Common causes of engine misfires include:

- Faulty Fuel Injectors (for spark-ignition engines).

- Low compression due to valve or piston issues

- Faulty sensors, such as the camshaft or crankshaft position sensor

- Fuel delivery problems like clogged filters or failing pumps

How do I replace the thermostat?

To replace the thermostat:

- Drain the coolant to prevent spills.

- Locate the thermostat housing, usually near the upper radiator hose.

- Remove the housing, take out the old thermostat, and clean the gasket surface.

- Install the new thermostat with a fresh gasket, reassemble, and refill coolant.

- Start the engine and check for leaks.

How do I check fuel line pressure?

To check fuel line pressure:

- Attach a fuel pressure gauge to the fuel rail’s test port.

- Turn the ignition to the ON position (without starting) to prime the pump.

- Compare the reading to the manufacturer’s specifications (typically between 20-30 psi for low-pressure systems and 3000+ psi for high-pressure common-rail systems).

- Start the engine and monitor pressure for fluctuations or drops.

What are signs of a clogged air intake?

Signs of a clogged air intake include:

- Reduced engine power and poor acceleration

- Black smoke from the exhaust due to rich fuel mixture

- Hissing noises from restricted airflow

- Increased fuel consumption and rough idling

How do I replace the crankshaft seal?

To replace the crankshaft seal:

- Remove components obstructing access, such as the harmonic balancer or timing cover.

- Carefully pry out the old seal using a seal puller.

- Clean the sealing surface thoroughly.

- Install the new seal, ensuring it is seated evenly.

- Reassemble components and check for oil leaks after starting the engine.

How do I inspect the flywheel for damage?

To inspect the flywheel for damage:

- Remove the transmission to access the flywheel.

- Check for cracks, scoring, or burn marks that indicate overheating.

- Inspect the ring gear teeth for wear or missing teeth.

- Verify that the flywheel is not warped by checking for runout with a dial indicator.

- If any damage is found, the flywheel should be resurfaced or replaced.

What causes low coolant levels?

Low coolant levels can result from:

- Leaks in hoses, the radiator, or the water pump

- A blown head gasket causing coolant to enter the combustion chamber

- Cracked engine components, such as the cylinder head or block

- An improperly sealed radiator cap causing coolant evaporation

Regular inspections can help identify and address the cause early.

How do I test the glow plug relay?

To test the glow plug relay:

- Locate the relay and disconnect it from the wiring harness.

- Use a multimeter to check for continuity between the relay’s terminals.

- Apply 12 volts to the control side of the relay and listen for a click indicating activation.

- If there’s no click or continuity, the relay is likely faulty and should be replaced.

What are the symptoms of a failing fuel pressure regulator?

Symptoms of a failing fuel pressure regulator include:

- Hard starting or stalling

- Poor fuel economy due to excessive fuel delivery

- Black smoke from the exhaust, indicating a rich fuel mixture

- Fuel leaks near the regulator

- Engine misfires or rough idling caused by inconsistent fuel pressure

How do I check the intake manifold for leaks?

To check for intake manifold leaks:

- Perform a visual inspection for cracks or damaged gaskets.

- Spray soapy water around the manifold joints while the engine runs; bubbles indicate a leak.

- Use a smoke machine to introduce smoke into the intake system and look for escaping smoke.

- Listen for a hissing sound, which often accompanies air leaks.

How do I replace the timing chain?

To replace the timing chain:

- Disconnect the battery and remove components obstructing the timing cover.

- Remove the timing cover and inspect the chain, gears, and tensioners.

- Align the timing marks on the crankshaft and camshaft before removing the chain.

- Install the new chain, ensuring the timing marks remain aligned.

- Reassemble the engine, start it, and verify proper timing.

How do I diagnose exhaust backpressure issues?

To diagnose exhaust backpressure issues:

- Install an exhaust backpressure gauge in place of the oxygen sensor or at the EGR port.

- Start the engine and record the pressure at idle and under load; excessive pressure indicates a restriction.

- Check for clogged catalytic converters, blocked mufflers, or damaged exhaust pipes.

- Resolve the issue by clearing or replacing the obstructed components.

How do I test the vacuum pump?

To test the vacuum pump:

- Connect a vacuum gauge to the pump’s output line.

- Start the engine and observe the vacuum reading; it should be within the manufacturer’s specified range, typically 18-22 inHg.

- If the vacuum is low, inspect for leaks in the hoses or a worn pump diaphragm.

- Replace the pump if it cannot maintain adequate vacuum pressure.

How do I identify signs of a worn-out camshaft?

Signs of a worn-out camshaft include:

- Tapping or ticking noises from the valve train

- Loss of power and poor acceleration

- Misfires due to improper valve timing

- Metal shavings in the oil, indicating wear

- Uneven wear patterns on cam lobes during a visual inspection

How do I replace the oil cooler?

To replace the oil cooler:

- Drain the engine oil and coolant.

- Remove the oil lines and any components obstructing the cooler.

- Unbolt the oil cooler and remove it from the engine.

- Install the new cooler with fresh gaskets and torque bolts to specifications.

- Refill with oil and coolant, then check for leaks after running the engine.

What causes engine hesitation during acceleration?

Engine hesitation during acceleration can be caused by:

- Clogged fuel injectors leading to poor fuel delivery

- A faulty throttle position sensor (TPS) affecting air-fuel mixture

- Vacuum leaks disrupting engine air intake

- Dirty mass airflow (MAF) sensor or bad ignition coils

Addressing these issues can restore smooth acceleration and performance.

How do I troubleshoot engine stalling issues?

To troubleshoot engine stalling:

- Check for fuel delivery issues, including clogged filters or weak fuel pumps.

- Inspect the idle air control valve (IAC) and throttle body for buildup.

- Test sensors like the crankshaft position sensor and camshaft sensor.

- Use a diagnostic scanner to read error codes for additional clues.

How do I check the voltage of the alternator?

To check alternator voltage:

- Set a multimeter to DC voltage.

- Place the positive lead on the battery’s positive terminal and the negative lead on the negative terminal.

- With the engine running, the voltage should be between 13.8 to 14.5 volts.

- If below this range, the alternator may be failing; if above, it may be overcharging.

What causes fuel dilution in the oil?

Fuel dilution in engine oil can be caused by:

- Leaking fuel injectors allowing fuel to seep into the crankcase

- Frequent short trips where the engine doesn’t reach operating temperature

- Worn piston rings allowing fuel to bypass into the oil

- Faulty high-pressure fuel pump seals

Excessive dilution can reduce oil’s lubricating properties, leading to engine wear.

How do I replace the harmonic balancer?

To replace the harmonic balancer:

- Remove the serpentine belt and any accessories blocking access.

- Use a harmonic balancer puller to remove the old balancer.

- Clean the crankshaft snout and align the keyway with the new balancer.

- Install the new balancer, torque the bolt to specifications, and reinstall the belt.

How do I test the coolant temperature sensor?

To test the coolant temperature sensor:

- Disconnect the sensor and use a multimeter to measure resistance.

- Compare the resistance to temperature values in the service manual.

- If resistance doesn’t change with temperature, the sensor may be faulty.

- Replace if necessary, as incorrect readings can affect engine performance.

What are signs of a failing turbo actuator?

Signs of a failing turbo actuator include:

- Loss of power and poor acceleration

- Check engine light with boost-related codes

- Overboost or underboost conditions

- Erratic turbocharger behavior or noisy operation

Use a diagnostic tool to test actuator movement and confirm functionality.

How do I replace the PCV valve?

To replace the Positive Crankcase Ventilation (PCV) valve:

- Locate the PCV valve on the valve cover or intake manifold.

- Remove the hose connected to the valve.

- Twist or pull the valve out, depending on the design.

- Install the new valve and reconnect the hose, ensuring a secure fit.

How do I identify and fix fuel leaks?

To identify and fix fuel leaks:

- Visually inspect fuel lines, injectors, and fittings for wet spots or fuel odors.

- Use a fuel pressure gauge to detect pressure drops.

- Tighten loose fittings or replace cracked hoses and worn seals.

- After repairs, run the engine to ensure no leaks remain.

What causes rough engine idling?

Common causes of rough idling include:

- Dirty fuel injectors or clogged air filters

- Vacuum leaks disrupting the air-fuel mixture

- Faulty spark plugs or ignition coils (for spark-ignition engines)

- Malfunctioning sensors, such as the MAP or IAC sensor

A diagnostic scan can help pinpoint the exact cause.

How do I diagnose injector timing issues?

To diagnose injector timing issues:

- Use a diagnostic scanner to monitor injector timing data.

- Check for misfires or rough running under load.

- Inspect the crankshaft and camshaft sensors that influence injector timing.

- If mechanical timing is off, verify the timing chain/belt alignment.

How do I check the differential pressure sensor?

To check the differential pressure sensor:

- Use a multimeter to test for proper voltage and continuity.

- Apply pressure to both ports and observe if the sensor responds accurately.

- Compare readings to manufacturer specifications.

- Replace if it shows inconsistent or no response.

How do I replace the engine mounts?

To replace engine mounts:

- Support the engine with a jack and block of wood to prevent damage.

- Remove the bolts securing the old mounts to the frame and engine.

- Install new mounts, ensuring proper alignment.

- Tighten bolts to the recommended torque and remove the support jack.

How do I clean the fuel tank?

To clean the fuel tank:

- Drain all fuel from the tank.

- Remove the tank if necessary for better access.

- Use a fuel system cleaner and rinse with clean fuel.

- Ensure the tank is completely dry before refilling with fresh fuel.

How do I inspect the belt tensioner for wear?

To inspect the belt tensioner:

- Check for cracks, bent parts, or worn pulleys.

- Manually move the tensioner to ensure it has smooth operation and proper tension.

- Listen for squeaking or rattling sounds when the engine is running.

- Replace if the tensioner feels loose or shows signs of damage.

What causes coolant boiling over?

Coolant boiling over can result from:

- A faulty radiator cap failing to maintain pressure

- Low coolant levels causing hot spots in the system

- Thermostat failure preventing proper coolant flow

- A clogged radiator or failing water pump reducing cooling efficiency

How do I check the glow plug resistance?

To check glow plug resistance:

- Set a multimeter to the ohms setting.

- Place one probe on the glow plug terminal and the other on the ground.

- A reading between 0.5 to 2 ohms typically indicates a good glow plug.

- Higher resistance or an open circuit means the glow plug is faulty.

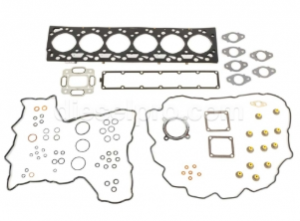

How do I replace the valve cover gasket?

To replace the valve cover gasket:

- Remove the valve cover bolts and lift off the cover.

- Remove the old gasket and clean the mating surfaces.

- Install the new gasket, ensuring proper alignment.

- Reinstall the valve cover and torque bolts to specifications.

What causes engine backfiring?

Engine backfiring can be caused by:

- Incorrect ignition timing leading to premature combustion

- A rich air-fuel mixture due to faulty sensors or injectors

- Exhaust leaks allowing unburnt fuel to ignite

- Damaged spark plugs or ignition components

How do I test the boost pressure sensor?

To test the boost pressure sensor:

- Disconnect the sensor and use a multimeter to check for proper voltage supply (typically around 5 volts).

- Measure the output voltage with the engine running; it should vary with throttle input.

- Use a diagnostic tool to compare sensor readings with actual boost pressure.

- Replace the sensor if it shows erratic or no response.

How do I reset the ECM after repairs?

To reset the Engine Control Module (ECM):

- Disconnect the battery cables and wait for about 15 minutes to clear residual power.

- Reconnect the battery and turn the ignition to the ON position without starting the engine.

- Use a diagnostic scanner to clear any trouble codes and initiate the ECM reset procedure if applicable.

- Start the engine and allow it to idle, so the ECM can relearn parameters.

How do I diagnose injector timing issues?

To diagnose injector timing issues:

- Use a diagnostic scanner to monitor injector timing data in real-time.

- Check for misfire codes or irregular engine performance.

- Inspect the crankshaft and camshaft position sensors, as they influence injector timing.

- If mechanical timing is suspected, verify timing chain/belt alignment.

How do I check the differential pressure sensor?

To check the differential pressure sensor:

- Use a multimeter to measure voltage and continuity across the sensor terminals.

- Apply controlled pressure to both ports of the sensor and observe if the voltage changes accordingly.

- Compare readings to manufacturer specifications; replace if inconsistent or unresponsive.

How do I replace the engine mounts?

To replace engine mounts:

- Support the engine with a jack and a block of wood to prevent damage.

- Remove the mounting bolts from the frame and engine.

- Remove the old mount and position the new one correctly.

- Tighten bolts to the recommended torque and remove the jack.

Parts Catalog Main Page for Cummins ISB Marine Engine

Cummins ISB 4.5 & Related Components

Cummins ISB 5.9 & Related components

Cummins ISB 6.7 & Related Components

Parts Catalog Main page for Cummins QSB Marine Engine

Cummins QSB 4.5 & Related Components

Cummins QSB 5.9 & Related Components

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588