Kona Hawaii fishing boat powered by Detroit Diesel 8.2 L photo provided by James David

The fuel system and governor of the Detroit Diesel 8.2L engine are integral components designed for optimal performance and efficiency. This guide provides a comprehensive examination of fuel injection components, governor adjustment, maintenance techniques, and troubleshooting approaches for common fuel system issues.

Overview of Fuel Injection Components

The Detroit Diesel 8.2L fuel system is a meticulously designed assembly to ensure precise fuel delivery and injection timing, essential for diesel engine efficiency. Below are its key components and their functions:

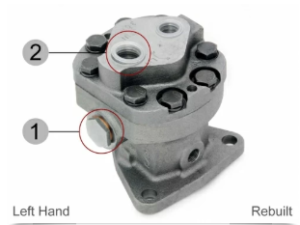

Fuel Pump

- A mechanical or gear-driven pump that draws fuel from the tank, pressurizes it, and delivers it to the injectors.

- Equipped with a filtration system to remove impurities, ensuring clean fuel delivery.

Injectors

- Each cylinder has its own injector designed to atomize fuel into a fine mist for efficient combustion.

- Injectors are precision-machined with high tolerances to ensure consistent performance.

Fuel Lines and Return System

- High-pressure lines deliver fuel from the pump to the injectors.

- A return system ensures excess fuel and air are cycled back to the fuel tank, preventing blockages and maintaining pressure consistency.

Filters

- Primary and secondary filters remove particulates and water, preventing damage to sensitive components.

Pressure Regulator

- Maintains consistent fuel pressure across the system to ensure accurate injection timing.

Adjusting and Maintaining the Governor

The governor plays a critical role in regulating engine speed under varying load conditions. Proper adjustment and maintenance are key to engine performance and longevity.

Governor Adjustment

- Preparation:

- Ensure the engine is off, and safety precautions are followed.

- Locate the governor assembly, which is typically mounted near the fuel pump.

- Adjusting Idle Speed:

- Loosen the idle speed adjustment screw.

- Adjust the screw to the manufacturer’s recommended idle speed (commonly around 600–700 RPM).

- Tighten the screw and start the engine to confirm idle speed.

- Setting High-Speed Limit:

- Locate the high-speed adjustment bolt.

- Adjust the spring tension to set the maximum RPM (as per factory specifications, typically 3000–3500 RPM for Detroit Diesel 8.2L engines).

- Ensure the engine operates smoothly at this speed without hunting or surging.

- Testing and Fine-Tuning:

- Run the engine under load conditions.

- Observe RPM fluctuations and make minor adjustments to the governor spring and buffer screw to eliminate instability.

Governor Maintenance

- Regularly inspect for wear on springs and linkage.

- Clean and lubricate moving parts to prevent sticking.

- Replace worn components to maintain reliability.

Troubleshooting Fuel System Issues

Diesel engines rely on a finely tuned fuel system for optimal performance. Common issues include poor starting, reduced power, and irregular idling.

Common Problems and Solutions

- Engine Hard to Start:

- Possible Cause: Air in the fuel lines.

- Solution: Bleed the fuel system to remove air pockets. Inspect and tighten loose fittings.

- Reduced Engine Power:

- Possible Cause: Clogged fuel filter.

- Solution: Replace both primary and secondary fuel filters. Check for contamination in the fuel tank.

- Irregular Idling or Surging:

- Possible Cause: Governor maladjustment or injector wear.

- Solution: Adjust the governor per specifications. Inspect and replace faulty injectors.

- Excessive Smoke from Exhaust:

- Possible Cause: Over-fueling or restricted air intake.

- Solution: Check injectors for leaks or clogging. Clean or replace the air filter.

- Fuel Leakage:

- Possible Cause: Damaged fuel lines or seals.

- Solution: Replace worn-out seals and inspect all connections for integrity.

Preventive Maintenance Tips

- Use high-quality diesel fuel with additives to reduce water contamination.

- Replace fuel filters at regular intervals or as recommended by the manufacturer.

- Perform routine inspections of fuel lines, fittings, and connections.

- Periodically test injectors for flow rate and spray pattern.

Conclusion

The Detroit Diesel 8.2L engine’s fuel system and governor are robust and efficient when properly maintained. By following the outlined maintenance and troubleshooting steps, operators can ensure reliable performance, minimize downtime, and extend the lifespan of their engines. For detailed specifications and advanced procedures, refer to authorized manuals or consult certified professionals.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588