Introduction

The hydraulic system inside the Twin Disc MG516 and MG5161 marine transmissions is the core of its operational integrity. It powers the engagement and disengagement of clutches, provides pressure for gear selection, and ensures smooth transitions between forward and reverse. If oil pressure drops, becomes erratic, or the hydraulic seals degrade, performance issues quickly follow—resulting in slipping gears, harsh engagement, or total failure of propulsion.

Rebuilt Twin Disc MG516 Marine Transmissions

Plate Kit For Twin Disc MG516 Marine Transmission

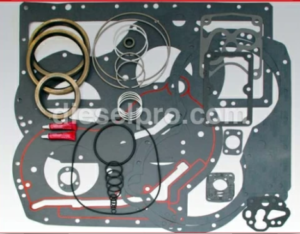

Gasket Kits For Twin Disc MG516 Marine Transmission

In this comprehensive guide, we will explore the complete hydraulic system servicing procedures including:

- How to check operating pressure

- What PSI ranges are acceptable for the MG516

- Where to inspect and how to replace critical hydraulic seals

- Tools and safety measures

- Signs of failure and preventative strategies

Disclaimer: Always refer to the OEM Twin Disc service manual for torque specs, hydraulic schematics, and model-specific service tolerances. This guide provides practical knowledge and is optimized for real-world commercial service environments.

Overview of the Hydraulic System in MG516 Marine Gear

Unlike simple mechanical transmissions, the Twin Disc MG516 uses a hydraulically actuated wet clutch system to engage forward and reverse gears. An engine-driven internal gear pump pressurizes oil and routes it through control valves to engage clutch packs. That oil is also responsible for lubrication and cooling.

Key hydraulic system components include:

- Hydraulic oil pump (driven off the input shaft)

- Forward clutch piston and reverse clutch piston

- Valve body or selector spool

- Oil cooler and return lines

- Filters and pressure ports

- Hydraulic seals, O-rings, and gaskets

If any component fails or pressure is out of spec, your MG516 can begin to exhibit gear slippage, delayed engagement, or overheating.

Checking Operating Pressure for Twin Disc MG516 Marine Gear

Routine pressure testing is one of the most important preventative maintenance tasks for the MG516. It allows you to monitor clutch performance, seal condition, and pump efficiency before symptoms arise.

When to Perform a Pressure Test

- Every 250 hours as part of a full inspection

- Any time shifting performance degrades

- After oil or filter change

- Post-seal replacement

- During gear slippage or delayed engagement

- Before and after major service

Tools Needed

- Hydraulic pressure test gauge (0–500 PSI range)

- Gauge hose and quick-connect fitting (compatible with MG516 port)

- Thread sealant or Teflon tape

- Flashlight and rags

- PPE: gloves, goggles, ear protection

Step-by-Step Procedure to Check Hydraulic Pressure

1. Warm Up the Transmission

- Run the engine for 10–15 minutes in neutral

- Oil temperature should reach at least 160°F (71°C) for accurate pressure reading

2. Locate the Test Port

- The MG516 features a built-in pressure test port—usually on the side or top of the control valve body

- If unsure, consult the OEM diagram or data plate

3. Install the Pressure Gauge

- Remove the plug from the port carefully using the correct hex or socket

- Thread in the gauge fitting using sealant to prevent leakage

- Do not overtighten—these are precision ports

4. Start the Engine and Observe Neutral Pressure

- With engine running and gear in neutral, observe pressure

- Acceptable range: 15–50 PSI (low pressure used for lubrication)

5. Engage Forward Gear

- Shift into forward while observing the gauge

- Pressure should jump to 250–310 PSI almost instantly

- Stabilize within 2 seconds

Slow engagement = worn clutch piston seals or pressure leak

6. Engage Reverse Gear

- Repeat the same check for reverse

- Pressure should match forward: 250–310 PSI

7. Ramp Up Engine Speed

- Increase RPM to 1,800

- Pressure should remain within spec

- Fluctuations may indicate pump or valve issues

8. Record and Compare

- Document all readings: RPM, temp, gear state, PSI

- If readings are out of range, proceed with diagnostics

What Pressure Deviations Mean

| Pressure Reading | Possible Issue |

| <15 PSI neutral | Low oil level, clogged filter, worn pump |

| <250 PSI engaged | Seal leak, worn clutches, faulty valve |

| >310 PSI engaged | Bypass valve stuck, wrong oil viscosity |

| Fluctuating | Air in system, cavitation, cracked suction line |

| Delayed pressure | Internal leakage, weak pump |

After Testing

- Shift back to neutral

- Turn off engine

- Carefully remove the pressure gauge

- Reinstall plug with fresh thread sealant

- Check for leaks

- Clean up spilled oil and log your results

Replacing Hydraulic Seals for Twin Disc MG516 Marine Gear

Hydraulic seals are responsible for containing pressure inside the clutch pistons and valve body. Over time, these seals degrade due to heat, wear, or chemical breakdown—leading to pressure loss, engagement delays, and oil leakage.

Common Hydraulic Seals in the MG516

- Forward Clutch Piston Seals

- Reverse Clutch Piston Seals

- Valve Body O-Rings

- Input Shaft Seal

- Output Shaft Seal

- Filter Base O-Ring

- Drain Plug Washer

- Cooler Line Seals and Adapters

Diesel Pro Power stocks complete aftermarket hydraulic seal kits compatible with MG516 and MG5161 models for full-service jobs.

Symptoms of Failing Hydraulic Seals

- Low or fluctuating pressure during operation

- Delay or soft engagement of gears

- Oil leak at mating surfaces or shaft housing

- Overheating from slipping clutches

- Pressure holds only at high RPM

- Foaming or contamination of hydraulic oil

Tools and Supplies for Seal Replacement

- Complete seal kit with OEM-matching O-rings, lip seals, and gaskets

- Torque wrench (0–250 ft-lbs)

- Hydraulic press or piston removal tools

- Seal puller and installer kit

- Snap ring pliers

- Non-chlorinated brake cleaner

- Seal lubricant (compatible with transmission oil)

- Soft mallet

- Clean workbench or cart

- Clean rags and nitrile gloves

General Replacement Procedure (Clutch Piston Seals)

This is a simplified overview. Always refer to OEM disassembly and reassembly procedures.

1. Drain the Transmission

- Fully drain oil and remove oil filter

- Remove external hoses and cooler lines as needed

2. Remove the Gear Housing Cover

- Unbolt the access cover (rear or side-mounted)

- Inspect gasket and clean mating surfaces

3. Disassemble the Clutch Assembly

- Remove snap rings holding clutch piston in place

- Carefully slide out the clutch piston

- Keep track of all clutch plates and steels in order

- Label or photograph sequence

4. Inspect and Replace Seals

- Remove old O-rings, quad-rings, or lip seals

- Clean seal grooves with a lint-free cloth

- Lubricate new seals lightly with transmission oil

- Press into place carefully to avoid twisting or pinching

- Inspect seal lips for full contact and alignment

5. Reassemble Clutch Packs

- Stack steel and friction discs in correct order

- Check wear tolerances (OEM specifies clutch clearance in mm or inches)

- Reinstall piston, compress evenly, and secure with snap rings

- Torque all bolts per specification using cross-pattern tightening

6. Replace Shaft Seals if Needed

- Use seal puller to remove input/output shaft seals

- Inspect shaft surface for grooves—polish or replace as necessary

- Press new seal with proper driver tool, lip facing inward

7. Replace Valve Body Seals

- Remove valve cover

- Inspect spool seals and replace any O-rings

- Clean thoroughly and re-torque evenly

8. Reinstall All Components

- New gaskets and washers at all openings

- Reinstall filter, fill with new oil, and purge air

9. Run Pressure Test

- After warm-up, confirm pressure stability

- Check for leaks at housing seams and ports

Preventative Tips for Extending Seal Life

- Use only correct oil type and viscosity

- Avoid pressure spikes from sudden gear shifts

- Keep oil clean with regular filter changes

- Inspect breather for clogging (pressure buildup)

- Avoid excessive idle operation without oil flow

- Store seal kits in dry, cool areas away from UV light

Advanced Troubleshooting and Diagnostics For Twin Disc MG516 Marine Gears

If you’ve replaced seals and still see pressure issues:

- Check oil cooler for restriction: Low flow reduces system pressure

- Verify pump shaft coupling: Slippage or shear causes low flow

- Test relief valve in valve body: May be stuck open

- Inspect clutch pack clearance: Over-clearance means weak engagement

- Check for air ingress in suction side (listen for cavitation)

You can also send an oil sample for lab testing to detect seal material, friction material, and wear metals.

Real-World Scenarios

Example 1: Tugboat with Delayed Reverse Engagement

Symptoms:

- 3–5 second delay into reverse

- Clunk sound and low RPM under load

Fix:

- Found degraded reverse piston O-ring

- Replaced with Diesel Pro seal kit

- Retested: pressure restored to 275 PSI

Example 2: Crew Boat Overheating in Forward Gear

Symptoms:

- Overheating at cruise speed

- Foamy oil on dipstick

Fix:

- Shaft seal leaking air into suction side

- Installed new seal and clamps

- Oil replaced, pressure normal, foaming resolved

Final Checklist After Servicing Hydraulic System

✅ All seals replaced with fresh components

✅ Oil level confirmed and topped off

✅ No leaks present at ports or shafts

✅ Neutral, forward, and reverse pressure within range

✅ Breather clear and clean

✅ Shift engagement tested under load

✅ Maintenance log updated with service date and technician info

Summary: Servicing the Hydraulic System in MG516 Marine Gear

The hydraulic system in the Twin Disc MG516 marine transmission is a precision-engineered network of pumps, valves, and seals working under pressure to ensure seamless operation. Routine inspection of pressure levels and proactive seal replacement are the foundation of reliable marine gear operation.

By following the correct procedures to:

- Test operating pressure

- Interpret pressure readings

- Replace critical hydraulic seals

- Verify component integrity

You prevent:

- Gear slippage

- Clutch wear

- Overheating

- Costly transmission failure

Parts Catalog for Twin Disc MG516 Marine Transmissions

Rebuilt Twin Disc MG516 Marine Transmissions

Plate Kit For Twin Disc MG516 Marine Transmission

Gasket Kits For Twin Disc MG516 Marine Transmission

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588