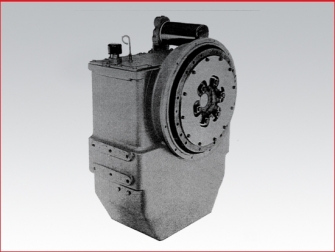

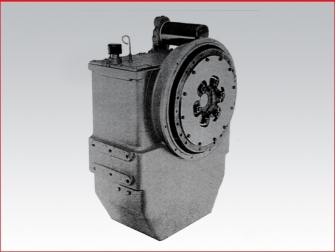

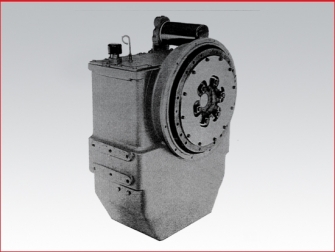

Twin Disc MG 516 Marine Transmission Parts - Rebuilt MG516 Gear Section

Loading...

Loading... Twin Disc MG516 Marine Transmission Parts — Rebuilt MG516 Gear Section

The Twin Disc MG516 is a proven workhorse marine transmission for operators who need dependable torque multiplication, smooth clutch engagement, and a ratio range that covers everything from fast planing hulls to heavy commercial workboats. This rebuilt MG516 gear section listing is designed to help you identify the right reduction ratio for your vessel, understand how the MG516 fits into typical propulsion layouts, and see exactly what you can expect when you order a professionally rebuilt, spin-tested unit from Diesel Pro Power. Below you’ll find detailed guidance on MG516 ratios from 3.00:1 up through 6.00:1, plus selection tips, service notes, and compatibility insights that reflect how these legacy Twin Disc gears are used in the real world.

Every rebuilt MG516 transmission we offer is spin tested prior to shipment to validate clutch operation, pressure, and shift response. That means you receive a transmission that has been function-checked dynamically for proper engagement and noise characteristics, so re-installation is straightforward and confidence-inspiring.

MG516 Ratio Options — What Each Reduction Really Does For You

MG516, 3.00:1 Reduction — Versatility For Mixed-Use Vessels

A 3:1 reduction is a highly versatile middle ground for operators who need a balance of thrust and propeller speed. With this setup, your propeller turns once for every three turns of the engine. In practical terms, that lets you swing a prop in the mid-diameter range without overloading while still keeping tip speed under control. It’s a favorite in multi-role boats that split their time between harbor transits, coastal runs, and occasional towing or gear hauling. Expect solid low-speed maneuverability with the MG516’s smooth clutch take-up and a comfortable cruise RPM range when properly matched to hull and prop.

Ideal use cases: small to mid-size commercial fishing vessels, crew boats, parasail and tour craft that need reliable acceleration with moderate bollard pull. If your vessel sees mixed duty cycles and spends time in both displacement and semi-planing regimes, 3.00:1 is often the right starting point for propeller sizing.

MG516, 3.50:1 Reduction — Added Thrust Without Sacrificing Control

Stepping up to 3.5:1 gives a meaningful bump in thrust potential for vessels that regularly push heavier loads or operate in stronger currents. The lower output shaft speed compared to engine RPM allows a larger-diameter or higher-pitch propeller, improving bite and reducing cavitation risk during hard maneuvers. On vessels with sizable gear aboard, this ratio can tame docking, improve station-keeping feel, and enhance overall throttle response at low speed.

Ideal use cases: trap and gillnet boats, pilot boats in high-current ports, patrol craft that alternate between long idle/loiter periods and quick bursts to cruise. If you’ve found a 3:1 marginal for holding power at the dock or during net retrieval, 3.5:1 can unlock the prop area you need.

MG516, 4.00:1 Reduction — Workboat-Oriented Pulling Power

At 4.00:1 the MG516 is clearly in the commercial-duty zone. The additional reduction supports larger, slower-turning wheels that deliver authoritative bollard pull and confident backing power—attributes that matter in towing, pushing, and frequent gear handling. Throttle modulation feels refined because the prop shaft is turning slower for a given engine RPM, which extends your controllable range during docking and line handling.

Ideal use cases: light tugs, pushboats, seine and trawl vessels, utility barges with frequent start-stop operations, and sightseeing boats that emphasize comfortable low-speed handling. Operators looking to improve bite in aerated water or reduce prop ventilation during crosswinds often settle on 4:1 when hull and aperture allow the prop diameter.

MG516, 4.50:1 Reduction — Heavy Lift In A Compact Footprint

If your primary requirement is torque at the wheel and you operate in confined waterways where control beats outright speed, 4.5:1 can be the sweet spot. It lets you swing even larger props at lower RPM, which reduces tip cavitation and noise while increasing thrust in forward and reverse. The MG516’s clutch characteristics make frequent shifting predictable—important for vessels that “work the gear” all day.

Ideal use cases: workboats with frequent towing evolutions, dive support vessels, research platforms, and harbor support craft that need assertive slow-speed maneuvering and holding power. If your current drivetrain struggles with prop slippage under load, 4.5:1 opens up a broader set of propeller solutions.

MG516, 5.00:1 Reduction — Maximum Thrust For Demanding Duty Cycles

A 5:1 MG516 is built for boats that live in high-load, low-speed environments: steady tow operations, river currents, and heavy sea states where thrust authority is non-negotiable. The large propellers enabled by this ratio deliver tremendous low-end push and backing control. Many operators moving to 5:1 report noticeably calmer throttle behavior in tight quarters because tiny engine RPM changes translate to even finer prop RPM adjustments.

Ideal use cases: dedicated towing vessels, heavier displacement hulls carrying deck equipment, and near-shore construction boats. If your missions rarely demand high transit speeds but always demand control and pull, 5:1 is engineered for that reality.

MG516, 6.00:1 Reduction — Slow-Turning Wheel, Serious Bite

At 6:1 you are firmly optimizing for thrust and precise low-speed control with the slowest prop shaft speeds in the MG516 lineup. This is a configuration for operators who routinely manage heavy gear or station-keep in challenging conditions. The ability to drive a significantly larger prop reduces cavitation, enhances reverse authority, and delivers consistent thrust in aerated or choppy water.

Ideal use cases: shallow-draft pushers, small assist tugs, specialty utility craft, and boats that must start, stop, and back frequently under load. If you’ve maximized propeller diameter within your aperture and still need more bite, 6:1 is often the decisive step that stabilizes handling.

How To Choose Your MG516 Ratio: Practical Selection Guide

Match Ratio To Mission, Not Just Horsepower

The MG516 will accommodate a range of engine outputs (legacy and modern) commonly found in commercial platforms. Rather than starting with engine HP alone, begin with your duty profile: how often you tow, how frequently you shift, typical sea state, and whether you value top-end speed or low-speed control. From there, pick the lowest ratio that provides the thrust you need without over-propping or inducing overload at cruise.

Propeller Aperture And Diameter Constraints

Your hull’s aperture, skeg, and rudder geometry usually dictate the maximum prop diameter. Each step up in reduction ratio allows a larger, slower-turning prop—great for thrust, but only if you have the physical clearance. Measure twice and consult your prop shop to ensure you can realize the ratio’s benefits.

Cavitation And Noise Considerations

Higher reductions keep tip speed down, reducing cavitation noise and improving crew comfort. If your current setup howls at backing power or ventilates in quartering seas, moving from 3:1/3.5:1 into the 4:1–6:1 range can cure that behavior—provided diameter and pitch are matched intelligently.

Reverse Authority And Station-Keeping

If docking, anchoring assistance, or gear retrieval are central to your operations, prioritize reverse bite and throttle granularity. The MG516’s clutch is well-suited to frequent shifts, and higher reductions magnify the benefit by slowing the wheel for precise control.

Fuel Efficiency And Engine Happiness

A properly matched reduction lets the engine operate in its most efficient band at your typical cruise speed. Under-reduction (prop too fast) forces compromised pitch and higher engine RPM at cruise, which burns more fuel. Over-reduction (wheel too slow/large) risks overload at mid-range. The right MG516 ratio is the one that keeps your engine squarely in its happiest torque window where it sips fuel and runs cool.

What “Rebuilt & Spin Tested” Means For The MG516

Spin-Tested Confidence

Each MG516 rebuilt gear section undergoes a spin test to confirm forward and reverse clutch engagement, hydraulic pressure stability, shift response, and noise characteristics. This dynamic validation helps ensure predictable installation and sea-trial results.

Core Return, Straightforward

Rebuilt MG516 units are sold with a refundable core deposit. You return a like-for-like MG516 core for evaluation; once received and accepted, your deposit is refunded per the stated core policy. Returning the core promptly keeps legacy MG516 units circulating for the fleets that rely on them.

Installation-Ready Details You’ll Appreciate

-

Cleaned and prepared housings and ports

-

Checked shafts and bearing fits for proper endplay

-

Fresh wear items and seals as part of the rebuild scope

-

Clutch performance validated under rotation during spin testing

(Exact component replacement can vary by core condition; the headline guarantee is a professionally rebuilt, spin-tested MG516 transmission configured to the ratio you select.)

MG516 In The Real World: Typical Applications & Operating Profiles

Commercial Fishing & Near-Shore Work

Long days at idle with frequent clutching are normal here. The MG516’s smooth engagement and consistent hydraulic behavior make it a favorite. Ratios around 3.5:1 to 4.5:1 are common for net handling and low-speed control, while 3:1 can be ideal for mixed-use boats that need to make time between grounds.

Towing, Pushing, And Harbor Assist

When bollard pull and reverse authority are the mission, 4:1–6:1 is where operators land. The slower prop shaft speeds allow big, heavily-loaded wheels to do their work without cavitating, and the MG516’s shifting smoothness provides confidence in tight quarters.

Tour, Pilot, And Patrol Boats

These vessels need crisp response and predictable handling at a range of speeds. The 3:1 to 3.5:1 ratios deliver a pleasing blend of acceleration and control. If you often fight current at low speed, you may prefer 3.5:1 for the extra bite.

Research, Survey, And Specialty Craft

Station-keeping, DP-lite maneuvers, and low-noise operation are easier with larger, slower-turning props. The MG516 with 4:1 or higher reductions helps maintain position with subtle throttle moves and less cavitation noise that can interfere with instruments.

Fitment Notes, Cases, And Interfaces

Case Styles & Mounting

MG516 gear sections are found in both “shallow” and “deep” case executions depending on ratio and application. Mounting footprints are consistent with the MG516 family, but verify your current stringer mounts and output flange spacing so the rebuilt unit drops in cleanly. When switching ratios, check shaft alignment and prop clearance because your optimal wheel spec may change.

Cooling & Lubrication

Like other Twin Disc gears in this class, the MG516 relies on clean oil and proper cooler flow. When replacing a gear or changing ratios, assess the health and capacity of your existing oil cooler and lines. Many chronic shifting complaints stem from heat or contaminated oil. A fresh start with clean lines and the correct cooler capacity pays off.

Controls & Cables

Hydraulic and mechanical control linkages should be inspected and adjusted during installation. The MG516’s smooth clutch operation is best realized when control throws and detents are set to spec and cable runs are low-friction with gentle bends.

Ordering A Rebuilt MG516 From Diesel Pro Power: What To Expect

Simple Ratio Selection

Choose from the available MG516 reductions—3.00:1, 3.50:1, 4.00:1, 4.50:1, 5.00:1, or 6.00:1—based on your vessel’s profile. If you’re undecided, we can talk through your typical load, desired cruise RPM, and prop constraints to narrow it down.

Core Return Coordination

You’ll receive clear instructions for returning your MG516 core. Package the old gear securely, protect exposed shafts and ports, and coordinate pickup. Once processed, your core deposit is returned in line with the posted policy.

Spin-Tested Documentation

Your rebuilt MG516 ships with confirmation that it was spin tested. That test provides peace of mind that forward, neutral, and reverse respond properly and that pressure/engagement are stable before the gear ever meets the water.

Maintenance & Service Tips For Longevity

Oil Quality Is Everything

Use clean, correct-spec oil and change on schedule. Send samples to a lab if your duty cycle is heavy or you’ve experienced slipping or overheating. Oil analysis can catch issues long before they become costly.

Cooler Health = Clutch Health

Restricted coolers shorten clutch life. Back-flush or replace coolers during gear replacement, and confirm seawater flow if your oil cooler is raw-water cooled. Keep zincs fresh when applicable.

Alignment & Mounts

Shaft alignment and resilient mounts matter. A rebuilt MG516 deserves a fresh alignment check after installation and again after the first sea trials as mounts settle. Vibration shortens bearing life and creates noise complaints.

Control Calibration

Ensure full travel at the gear lever and confirm detents. Sticky cables or misadjusted linkages can mimic clutch problems. Replace questionable cables rather than chasing intermittent engagement issues.

Troubleshooting Feel & Performance (Operator-Centric)

Harsh Engagement Or “Bump” Into Gear

Often a linkage or idle speed issue rather than a gear problem. Verify engine idle is in the recommended range and that control throws are smooth and exact. Higher reductions (e.g., 5:1–6:1) can also mask minor idle irregularities by further slowing the prop.

Slippage At High Load

Check oil level and temperature first. If oil is hot or contaminated, performance will suffer. Prop pitch may be too aggressive for the engine/ratio combo; de-pitching a small amount can stabilize load without sacrificing control.

Noisy Reverse

Cavitation and aeration are common culprits. Consider moving up in reduction (e.g., from 3:1 to 3.5:1 or 4:1) to turn a larger, slower prop, and verify the prop has adequate immersion and clean leading edges.

Why Diesel Pro Power For Your Rebuilt Twin Disc MG516

Spin-Tested Rebuilds You Can Trust

Every MG516 we ship has been spin tested to verify engagement, pressure, and consistent behavior. That pre-delivery assurance reduces surprises during sea trials.

Legacy Model Expertise

We specialize in classic Twin Disc models that keep commercial fleets moving. If your boat depends on an MG516, you need a partner who knows the common fit-up quirks, ratio trade-offs, and service realities of these gears.

Fast, Clear Communication

From ratio guidance to core logistics, you’ll get direct, practical answers. Tell us your hull, prop limits, and mission; we’ll help you land on the right MG516 configuration.

Global Customer Base, Proven Reliability

With tens of thousands of satisfied customers worldwide, Diesel Pro Power supports fleets that operate far from home. Our packaging, documentation, and support reflect that reality.

End-To-End Parts Support

Beyond the gear itself, you can source related parts—coolers, control components, seals, and more—so your installation is complete, tidy, and reliable from day one.

Ratio-By-Ratio Quick Reference (MG516)

3.00:1 — Balanced thrust and cruise speed; mixed-use boats that split time between harbor work and coastal transits.

3.50:1 — Extra bite for current and load; better low-speed control without a big speed penalty.

4.00:1 — Workboat leaning; better bollard pull and confident reverse for towing and gear handling.

4.50:1 — Heavy thrust focus; quiet, low-cavitation operations in tight quarters and strong winds.

5.00:1 — High-demand commercial duty; steady towing, river currents, and construction tasks.

6.00:1 — Maximum low-speed authority; largest wheel your aperture allows for serious pull and precision.

Ordering Checklist For A Smooth MG516 Swap

-

Confirm ratio based on mission and prop constraints.

-

Verify propeller clearance for potential diameter changes.

-

Assess cooler capacity and plan to flush or replace.

-

Inspect mounts and alignment tools ahead of install.

-

Review control linkages (replace sticky cables).

-

Plan the core return—have pallets, protection, and pickup ready.

-

Schedule a post-install alignment check after sea trials.

Frequently Asked Questions About The MG516

Can I change ratios when replacing my MG516?

Yes. Many operators use a replacement window to move up or down in ratio to better match their duty profile. Just confirm prop room and engine cruise targets before committing.

Will a higher reduction always slow my boat?

Not necessarily. With the right prop, you may hold similar cruise speeds while gaining control and efficiency—and you’ll almost always improve low-speed authority.

Do rebuilt MG516 units come tested?

Yes. Each unit is spin tested so you receive a transmission with proven forward and reverse engagement and stable hydraulic response.

What if my old core is damaged?

Heavily damaged cores may affect the refundable amount. We’ll evaluate fairly and communicate clearly so you know where you stand.

Can the MG516 handle frequent shifting?

Absolutely. It’s a core strength of this model family. Just maintain clean, cool oil and keep controls calibrated.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588