Introduction

The Cummins B Series engine family is one of the most popular and versatile diesel engine platforms in the world. Renowned for their durability, efficiency, and ease of maintenance, these engines are widely used across marine, industrial, agricultural, trucking, and construction applications. Whether powering a fishing vessel, a farm tractor, or a heavy-duty truck, these engines have earned a reputation for longevity and performance.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

Overview of Cummins B Series Engines (6B, 6BT, 6BTA, 4B, 4BT, 4BTA)

Cummins B Series engines are available in four-cylinder (4B, 4BT, 4BTA) and six-cylinder (6B, 6BT, 6BTA)configurations. While they share a common architecture, there are key differences:

- 6B (Naturally Aspirated) – No turbocharger, making it simpler but less powerful.

- 6BT (Turbocharged) – Equipped with a turbocharger for increased power and fuel efficiency.

- 6BTA (Turbocharged and Aftercooled) – Features both a turbocharger and an aftercooler, which lowers intake temperatures and increases efficiency.

- 4B, 4BT, and 4BTA – These four-cylinder versions offer a more compact alternative while retaining durability and performance.

The turbocharged and aftercooled (BTA) variants provide the best performance and fuel efficiency but require more attention to cooling system maintenance.

Common Applications of Cummins B Series Engines

Cummins B Series engines power a wide range of commercial and industrial equipment, making them a preferred choice in demanding industries:

Marine Applications

- Used in commercial fishing vessels, tugboats, yachts, and workboats.

- The 6BTA is one of the most popular marine diesel engines, known for its fuel efficiency and reliability.

- Requires regular maintenance on heat exchangers, seawater pumps, and fuel injectors due to harsh operating conditions.

Industrial Applications

- Found in generators, water pumps, compressors, and drilling rigs.

- Requires consistent fuel and cooling system maintenance to prevent breakdowns in remote locations.

Agricultural Applications

- Powers tractors, irrigation pumps, and harvesting equipment.

- Benefits from long service intervals and high torque at low RPMs, making it ideal for heavy farm work.

Trucking Applications

- Common in medium-duty trucks, buses, and delivery vehicles.

- Provides excellent fuel efficiency and reliability, reducing downtime for fleet operators.

Construction Applications

- Used in excavators, bulldozers, and wheel loaders.

- High torque and rugged build quality allow it to handle extreme conditions in construction sites.

Importance of Regular Maintenance and Servicing

Routine maintenance is critical for ensuring long engine life, maximum performance, and fuel efficiency. Without regular servicing, issues such as clogged fuel injectors, overheating, and low oil pressure can lead to expensive repairs or even catastrophic engine failure.

Key maintenance benefits include:

✔ Extending engine lifespan – Many Cummins B Series engines surpass 500,000 to 1,000,000 miles when properly maintained.

✔ Improving fuel efficiency – Clean air filters, properly functioning injectors, and a well-maintained turbocharger reduce fuel consumption.

✔ Preventing costly repairs – Detecting and addressing minor issues before they escalate avoids expensive breakdowns.

✔ Maximizing uptime – Essential for businesses that rely on trucking, marine, or industrial equipment.

What This Guide Covers

This comprehensive guide provides detailed instructions on servicing Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engines. Whether you’re an experienced mechanic or a first-time diesel owner, this guide will help you:

- Identify common issues and troubleshoot problems effectively.

- Perform regular maintenance such as oil changes, fuel filter replacements, and valve adjustments.

- Understand the fuel system, cooling system, electrical system, and turbocharger maintenance.

- Decide when an engine overhaul or rebuild is necessary.

By following recommended service intervals and troubleshooting techniques, you can keep your Cummins B Series engine running efficiently for years to come.

Cummins B Series Maintenance: What You Need to Know

Essential Maintenance Intervals

Oil and Filter Changes

- Change oil every 250-300 hours or every 6,000-10,000 miles.

- Replace the oil filter at every oil change to prevent sludge buildup.

- Use high-quality diesel engine oil (15W-40 for most climates).

Oil Filter & Related Components for Cummins 6BT engine

Fuel System Maintenance

- Replace the fuel filter every 10,000-15,000 miles or 500 hours.

- Drain the water separator regularly to prevent fuel contamination.

- Inspect injectors for leaks or poor spray patterns to maintain fuel efficiency.

Fuel Filter & Related Components for Cummins 4B Marine & Industrial Engines

Fuel Filter & Related Components for Cummins 4BT Marine & Industrial Engines

Fuel Filter & Related Components for Cummins 4BTA Marine & Industrial Engines

Fuel Filter & Related Components for Cummins 6B Marine & Industrial Engines

Fuel Filter & Related Components for Cummins 6BT Marine & Industrial Engines

Fuel Filter & Related Components for Cummins 6BTA Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Injector & Related Components for Cummins 4B Marine & Industrial Engines

Injector & Related Components for Cummins 4BT Marine & Industrial Engines

Injector & Related Components for Cummins 4BTA Marine & Industrial Engines

Injector & Related Components for Cummins 6B Marine & Industrial Engines

Injector & Related Components for Cummins 6BT Marine & Industrial Engines

Injector & Related Components for Cummins 6BTA Marine & Industrial Engines

Cooling System Maintenance

- Flush and replace coolant every two years or 4,000 hours to prevent corrosion.

- Inspect the radiator, water pump, and hoses for leaks.

- Ensure the thermostat functions correctly to maintain operating temperatures.

- Fresh Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

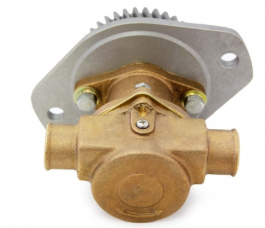

Marine Water Pump for Cummins 6B Series Marine Engines

Marine Raw Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

- Fresh Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Air Intake and Turbocharger Maintenance

- Replace the air filter every 15,000-30,000 miles or more frequently in dusty environments.

- Check for boost leaks to maintain proper turbo pressure.

- Clean the intercooler regularly to improve turbo efficiency.

Turbocharger & Related Components for Cummins 6BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 6BTA Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BTA Marine & Industrial Engines

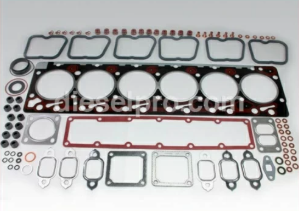

Valve and Cylinder Head Maintenance

- Adjust valves every 150,000 miles or 5,000 hours to maintain proper clearance.

- Inspect cylinder head bolts and gaskets for wear and potential leaks.

- Check for excessive blow-by, which may indicate worn piston rings.

Cylinder Head & Related Components for Cummins 6B Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BTA Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4B Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BTA Marine and Industrial Engines

Why Proper Maintenance is Critical

Avoiding Costly Repairs

Ignoring routine maintenance can lead to expensive failures such as:

- Blown head gaskets from overheating.

- Worn turbochargers from lack of oil changes.

- Clogged fuel injectors, causing power loss and poor fuel economy.

Maximizing Performance and Efficiency

- A well-maintained fuel and air intake system ensures optimal combustion and horsepower output.

- Turbocharger and aftercooler maintenance can prevent excessive exhaust temperatures and keep fuel costs low.

Increasing Engine Lifespan

- Preventing oil sludge buildup and excessive wear on bearings keeps the engine running beyond 1,000,000 miles.

- Proper coolant maintenance avoids overheating, which can warp cylinder heads and cause irreversible damage.

Final Thoughts

Cummins B Series engines are legendary for their durability, but only when properly maintained. By following the recommendations in this guide, you can:

✔ Extend the life of your engine and avoid costly overhauls.

✔ Ensure maximum fuel efficiency and optimal performance.

✔ Prevent unexpected breakdowns and downtime.

This guide will take you through step-by-step maintenance procedures, troubleshooting tips, and expert insights to help you keep your Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engine running at peak efficiency.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588