Cummins 6BT Engine Parts - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Cummins 6BT Engines

The Cummins 6BT 5.9 engine has earned a reputation for durability and performance in a wide range of industrial, marine, and commercial applications. To keep these engines performing at their best, it’s essential to ensure the cylinder head and its related components are well-maintained or replaced with high-quality parts when needed. At Diesel Pro Power, we offer new cylinder heads and all the critical components required for a proper top-end rebuild or repair of your Cummins 6BT engine.

New Cylinder Head Assemblies for Cummins 6BT

Assembled Cylinder Head with Valves and Springs

We offer fully assembled cylinder heads for Cummins 6B, 6BT, and 6BTA 5.9 engines. These new heads come with intake and exhaust valves already installed, along with valve springs and injector tubes. The injector tubes are sized to match the 7mm injectors commonly used in marine and industrial 6BT configurations.

These heads are ideal for anyone doing a full top-end rebuild or replacing a cracked or worn-out casting. Because the head is pre-assembled, it reduces installation time and eliminates the need for separate valve lapping, spring installation, or tube pressing.

Marine-Specific Cylinder Head Option

For marine applications, we also provide cylinder heads specifically machined and assembled for marine use. These are designed to withstand prolonged operation at high RPMs and exposure to salty, humid environments. They are built with corrosion-resistant hardware and compatible with 6BT marine fuel system configurations.

Valvetrain Components for 6BT Cylinder Head Assemblies

A functioning cylinder head depends on high-quality valvetrain components. If you're performing a top-end refresh, it’s a good idea to replace worn valves, springs, rotators, and guides. Below are the key components available individually to complete your head overhaul.

Intake and Exhaust Valves

We carry replacement intake and exhaust valves for the Cummins 6BT. Each cylinder requires one intake valve and one exhaust valve. These are designed for high heat resistance and long-term sealing under pressure. Whether you're replacing just one valve or all six, you can trust our valves to meet OEM performance standards.

Valve Springs

The valve springs in the 6BT engine control the movement of the valves under high RPM and combustion pressures. We offer springs that are compatible with stock cam profiles and valve lift specifications for both industrial and marine-rated engines. If your engine has been in service for thousands of hours or has suffered valve float, replacing the valve springs is essential.

Valve Rotators (Rotocoils)

Valve rotators are located on the exhaust valves and help prevent valve seat wear by rotating the valve slightly each time it opens and closes. If your current rotators are worn or not functioning properly, this can lead to uneven valve face wear and premature seat erosion. Replacing them during a cylinder head rebuild is recommended.

Valve Guides

Valve guides stabilize the movement of the intake and exhaust valves as they open and close. Excessively worn guides can result in oil consumption, valve misalignment, and loss of compression. We supply both intake and exhaust valve guides, machined to exact OEM tolerances for proper valve fit and oil control.

Valve Guide Seals

These seals prevent oil from leaking down the valve stems into the combustion chamber. Our seals are compatible with both intake and exhaust guides and offer long service life under high-heat operating conditions. It’s standard best practice to replace valve seals anytime you remove the cylinder head.

Valve Inserts

Valve seat inserts are critical wear surfaces where the valve face contacts the cylinder head. Over time, especially in marine and high-load applications, these inserts can erode or crack. We offer intake and exhaust valve seat inserts that can be machined into your existing head if needed.

Cylinder Head Bolts for Cummins 6BT

The Cummins 6BT uses a combination of cylinder head bolts in various lengths. Each bolt must be torqued precisely to maintain a proper seal between the cylinder head and the block.

We carry all head bolts required for both 4-cylinder (4BT) and 6-cylinder (6BT) configurations. It’s important to replace head bolts any time the head is removed, as reused bolts may not maintain proper clamping force. We provide both the shorter bolts used around the perimeter and the longer bolts required for the center areas of the cylinder head.

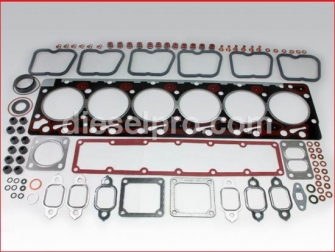

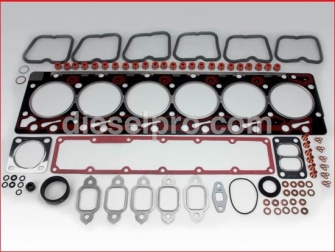

Gasket Sets for Cylinder Head Installation

Upper Gasket Sets

To properly reinstall the cylinder head, a full upper gasket set is necessary. These include the head gasket, valve cover gasket, intake and exhaust manifold gaskets, injector seals, and other critical sealing components. We offer upper gasket sets in both standard and oversize variants to accommodate blocks that have been resurfaced or heads that require slightly thicker gaskets to restore proper piston-to-head clearance.

Valve Cover Gaskets

A fresh valve cover gasket ensures a leak-free seal between the valve cover and the cylinder head. This is particularly important for marine engines, where oil leaks can cause contamination and safety issues. We offer standard gray gaskets compatible with the 6BT valve cover and pushrod architecture.

Push Rod Cover Gasket

The push rod cover gasket seals the lower portion of the valvetrain housing. It’s often overlooked during top-end work but should be replaced to prevent oil leaks along the side of the engine block.

Push Rods and Rocker Hardware

Push Rods

We supply push rods that match the Cummins 6BT valve train design. These rods transmit camshaft motion to the rocker arms and must remain straight and free of wear at each end. If your rods are bent, worn, or exhibit surface damage, replacing them ensures proper valve actuation and engine timing.

Rocker Arm Hardware

For customers performing a full top-end rebuild, we also provide the hex nuts used to secure the rocker arms. These nuts must be torqued properly to maintain rocker geometry and prevent valve lash issues. Replacing worn or deformed rocker nuts is a simple but important step.

Related Components

Temperature Switches

While not directly part of the cylinder head assembly, temperature switches are frequently replaced at the same time during top-end maintenance. These switches monitor coolant temperatures and help prevent overheating by alerting operators or triggering shutdown systems. We offer temperature switches compatible with Cummins 6BT engines, especially those used in marine environments where overheating must be detected immediately.

Fuel Manifolds

Fuel manifolds, especially on marine 4BT and 6BT engines, help distribute fuel from the lift pump to each injector. While not part of the cylinder head itself, they run along its side and are often removed during cylinder head service. If your manifold is corroded or leaking, it’s wise to replace it during the same service window.

Why Choose Diesel Pro Power for Your 6BT Cylinder Head Needs?

With over 40,000 satisfied customers worldwide, Diesel Pro Power is trusted by professionals across marine, industrial, and construction industries. Our parts are precision-manufactured to OEM standards, and our assembled cylinder heads save you hours of labor while delivering peace of mind. All products are backed by our expert technical support team and fast international shipping.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588