Introduction

The lubrication and cooling systems in Cummins C Series engines (6C, 6CT, 6CTA) are vital for ensuring long-lasting performance, efficiency, and reliability. These systems work together to keep the engine running at the optimal temperature while minimizing friction and wear on moving components. Proper maintenance of these systems is essential to prevent overheating, reduce wear, and extend the life of the engine.

Lubrication System & Related Components for Cummins 6C Marine & Industrial Engines

Lubrication System & Related Components for Cummins 6CT Marine & Industrial Engines

Lubrication System & Related Components for Cummins 6CTA Marine & Industrial Engines

Freshwater Cooling System & Related Components for Cummins 6C Marine & Industrial Engines

Freshwater Cooling System & Related Components for Cummins 6CT Marine & Industrial Engines

Freshwater Cooling System & Related Components for Cummins 6CTA Marine & Industrial Engines

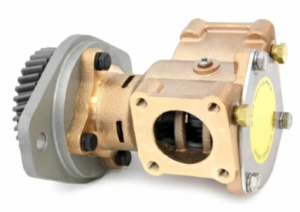

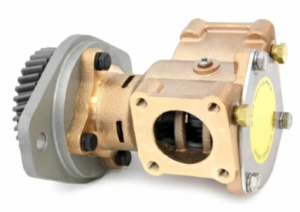

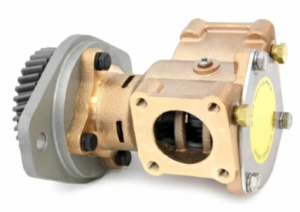

Raw Water Pump & Related Components for Cummins 6C Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6CT Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6CTA Marine & Industrial Engines

This guide covers:

- The Importance of Lubrication in Engine Longevity

- Inspecting and Servicing the Oil and Cooling Systems

- Preventing Overheating Through Regular Maintenance

By understanding how these systems operate and implementing the best maintenance practices, Cummins engine owners can ensure their engines remain in peak operating condition.

1. The Importance of Lubrication in Engine Longevity

A. How the Lubrication System Works

The lubrication system in Cummins C Series engines is designed to reduce friction, dissipate heat, and prevent wear of critical engine components. The system consists of the following major components:

- Lubricating Oil Pump:

New oil pump, for use in Cummins 6C, 6CT and 6CTA engines.

- A gear-driven pump that circulates oil throughout the engine.

- Delivers oil under pressure to bearings, camshaft, pistons, and other moving parts.

- Oil Cooler:

Cummins Oil Cooler for 6C, 6CT, 6CTA, ISC

- Regulates oil temperature by transferring excess heat from the oil to the coolant.

- Helps maintain optimal viscosity and prevents overheating.

- Oil Filter:

Oil Filter for Cummins 6CTA

- Removes dirt, debris, and contaminants from the oil before it circulates back into the engine.

- Ensures clean lubrication and prevents clogging of small oil passages.

- Dipstick and Oil Pan:

- The dipstick allows users to monitor oil levels.

- The oil pan collects oil at the bottom of the engine for recirculation.

B. Why Lubrication is Essential for Longevity

- Reduces Friction:

- Metal components in an engine operate under extreme pressures.

- Proper lubrication forms a protective film that prevents metal-on-metal contact.

- Prevents Overheating:

- Heat generated by friction is absorbed and carried away by the oil.

- The oil cooler helps maintain safe operating temperatures.

- Protects Against Contaminants:

- Oil collects carbon deposits, metal shavings, and other debris.

- The oil filter traps contaminants and prevents premature engine wear.

- Enhances Engine Efficiency:

- Proper lubrication reduces internal resistance, improving fuel efficiency.

- A well-lubricated engine produces more power with less effort.

2. Inspecting and Servicing the Oil and Cooling Systems

A. Inspecting the Lubrication System

- Checking the Oil Level:

- Use the dipstick to check oil levels before every operation.

- The oil should be between the MIN and MAX marks on the dipstick.

- If the oil appears milky or contains debris, change it immediately.

- Inspecting for Leaks:

- Check for oil drips under the engine.

- Inspect oil lines, gaskets, and seals for leaks.

- Ensure the oil drain plug is properly tightened.

- Oil Filter Inspection and Replacement:

- Change the oil filter every 250–500 hours of operation.

- Always use genuine Cummins oil filters to ensure proper filtration.

- Lubricating Oil Cooler and Pump Check:

- The oil cooler should be free of obstructions and corrosion.

- Check oil pump pressure with a gauge to ensure adequate circulation.

B. Inspecting the Cooling System

The cooling system prevents overheating and helps maintain optimal engine efficiency. Regular inspections ensure the system is working correctly.

- Coolant Level and Condition Check:

- Check the coolant level daily before starting the engine.

- Coolant should be a 50/50 mix of antifreeze and distilled water.

- Inspect the coolant for signs of oil contamination, which could indicate a blown head gasket.

- Radiator and Hoses Inspection:

- Look for cracks, leaks, or bulging hoses.

- Ensure the radiator fins are clean and free of debris.

- Remove dirt and grime from the radiator to maintain airflow.

- Water Pump and Thermostat Inspection:

- The water pump is belt-driven and circulates coolant through the engine.

- Listen for unusual noises that may indicate bearing wear in the pump.

- The thermostat regulates coolant flow and should be replaced every two years.

- Pressure Cap and Fan Check:

- The pressure cap maintains system pressure, preventing boiling.

- Check the cooling fan for loose mounting bolts, damage, or imbalances.

3. Preventing Overheating Through Regular Maintenance

Overheating is a common issue in diesel engines, and preventive maintenance is the best way to avoid it.

A. Common Causes of Overheating

- Low Coolant Levels – Caused by leaks in the radiator, hoses, or water pump.

- Clogged Radiator – Dirt and debris reduce cooling efficiency.

- Faulty Thermostat – Prevents proper coolant circulation.

- Malfunctioning Water Pump – Reduces coolant flow, causing high temperatures.

- Blocked Airflow – Dust and dirt block radiator fins, restricting heat dissipation.

B. Cooling System Maintenance Schedule

| Task | Frequency | Action Required |

| Check Coolant Level | Daily | Inspect expansion tank and refill as needed. |

| Inspect Radiator and Hoses | Weekly | Look for leaks and debris. |

| Flush Cooling System | Every 2 Years | Drain old coolant and replace with fresh coolant. |

| Replace Thermostat | Every 2 Years | Ensure proper coolant temperature regulation. |

| Inspect Water Pump | Every 500 Hours | Check for leaks and proper function. |

| Pressure Test System | Annually | Identify leaks and weak components. |

C. Steps to Prevent Overheating

- Regularly Flush the Cooling System:

- Over time, coolant accumulates contaminants that can clog the system.

- Flushing ensures proper heat dissipation and prevents corrosion.

- Maintain Proper Belt Tension:

- A loose belt reduces water pump efficiency, leading to inadequate cooling.

- Check for wear and adjust or replace the belt as necessary.

- Use the Right Coolant:

- Using Cummins-recommended coolant prevents scaling and corrosion.

- Avoid using only water, as it lacks anti-corrosive properties.

- Check for Exhaust Gas Leaks into the Cooling System:

- A leaking head gasket can allow combustion gases into the cooling system.

- This causes bubbling in the coolant reservoir and reduces cooling efficiency.

Conclusion

The lubrication and cooling systems in Cummins C Series engines (6C, 6CT, 6CTA) are critical for ensuring longevity, efficiency, and reliability. Proper maintenance of these systems reduces wear, prevents overheating, and enhances overall engine performance.

Key takeaways:

- Lubrication System Maintenance: Regular oil changes, filter replacements, and leak inspections prevent premature engine wear.

- Cooling System Inspections: Checking coolant levels, flushing radiators, and monitoring the water pump help prevent overheating issues.

- Preventive Measures: Adhering to a strict maintenance schedule ensures consistent engine performance and durability.

By following these best practices, Cummins engine owners can maximize efficiency, reduce downtime, and increase the lifespan of their engines.

Lubrication System & Related Components for Cummins 6C Marine & Industrial Engines

Lubrication System & Related Components for Cummins 6CT Marine & Industrial Engines

Lubrication System & Related Components for Cummins 6CTA Marine & Industrial Engines

Freshwater Cooling System & Related Components for Cummins 6C Marine & Industrial Engines

Freshwater Cooling System & Related Components for Cummins 6CT Marine & Industrial Engines

Freshwater Cooling System & Related Components for Cummins 6CTA Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6C Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6CT Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6CTA Marine & Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588