Cummins 6C Engine Parts - Marine Water Pump Section

Loading...

Loading... -

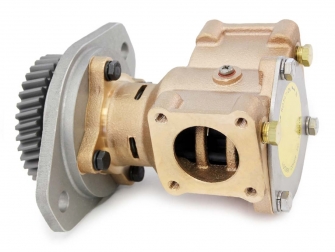

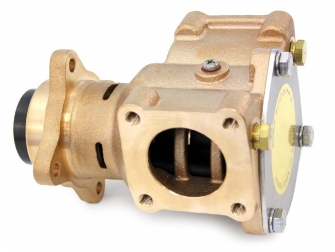

Marine Water Pump for Cummins C Series Marine Engines

3912139

NEW, Enhanced-flow bronze seawater pump; Port type: hose connection, 2" inlet and 1 3/4" outlet; for Cummins C Series marine engines.

Price: $ 1,168.02 -

Marine Water Pump for Cummins B, C, QSB and QSL Engines

P1730C

NEW, Bronze seawater pump with 11° off-center shaft mounting holes; Port type: flange, 1 3/4" inlet/outlet; for Cummins B, C, QSB and QSL marine engines.

Price: $ 927.17 -

Marine Water Pump for Cummins C Series Marine Engines

S7627

NEW, Marine-grade bronze seawater pump with 16° off-center shaft mounting holes; Port type: flange, 1 3/4" inlet/outlet; for Cummins C Series marine engines.

Price: $ 998.70 -

Marine Water Pump for Cummins B, QSB and C Series Marine Engines

S7608

NEW, Bronze high-flow seawater pump; Port type: flange, 1 3/4" inlet/outlet; for Cummins B, QSB and C Series marine engines.

Price: $ 991.03 -

Cummins Impeller for Key Shaft

17000K

3-½ Inch Height 2-⅞ Inch Width 3- 5/16 Inch DiametePrice: $ 84.06 -

-

Cummins Impeller for Splined Shaft

27000K

12 blades, 2 7/8" depth, 3 5/12" diameter, 3/4" shaft diameterPrice: $ 120.45 -

-

-

-

-

-

Hose Plain for Cummins 6C, 6CT & 6CTA engines

63241N

To connect the heat exchanger outletPrice: $ 69.90 -

-

-

Zinc for Marine Engine - for Marine Water Pumps

E2C

For Detroit heat exchanger For Cummins heat exchanger and aftercooler For Brass plug NPT 1/2", zinc length 2"Price: $ 27.53 -

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 20.77 -

-

-

-

-

Hose Elbow for Cummins 6C, 6CT & 6CTA engines

3912177

To connect the exhaust outlet with the Sea water pump tube.Price: $ 124.70 -

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a cooland and fuel Hose

5104592

Effective Diameter Range:

Minimum 1", Maximum 1.5"

Price: $ 4.52 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 16.50 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 16.68 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 17.19 -

-

Controls Cables & More...

-

Marine Control

-

Industrial Cable

-

Marine Cables 1/16 thread

-

Marine Cables 1/4 thread

-

Marine Steering

-

Rubber Bearing

-

Searchlight

-

Marine Bulb

-

Navigation Light

Cummins 6C Marine Raw Water Pump and Cooling System Parts

The Cummins 6C marine engine is known for its balance of horsepower, fuel economy, and reliability in demanding marine environments. Whether it's propelling commercial vessels, supporting standby marine generators, or powering workboats, the 6C requires a dependable raw water cooling system to operate safely and efficiently.

This catalog provides a comprehensive selection of raw water pump and cooling components specifically designed for Cummins 6C engines. These include marine water pumps, impellers, gaskets, hoses, zincs, and other accessories that ensure your cooling system performs at its best under marine conditions.

Marine Water Pumps for Cummins 6C Engines

Raw water pumps are at the heart of the cooling system for Cummins 6C marine engines. These pumps draw seawater through strainers and into the heat exchanger to cool the engine's internal coolant loop.

Standard Marine Water Pump for Cummins C Series

Designed with a 2” hose barb inlet and 1 ¾” hose barb outlet, this raw water pump is ideal for direct replacement on marine C Series engines. Built from corrosion-resistant materials, this pump is engineered for long service life and consistent flow.

-

Inlet Size: 2” hose barb

-

Outlet Size: 1 ¾” hose barb

-

Fitment: Designed specifically for Cummins 6C and 6C8.3 engines

This model is particularly useful for legacy engines where OE-style configuration is needed for straightforward installation.

Bidirectional Raw Water Pump with Offset Mount

For installations where direction of rotation varies or gear alignment requires flexibility, the bidirectional pump offers a solution:

-

Mounting Holes: 11° offset from the center of the drive gear shaft

-

Rotation: Bidirectional—supports both clockwise and counterclockwise pump rotation

-

Port Type: 1 ¾” flange connections

This makes it ideal for replacement in marine gensets and propulsion engines across the Cummins B, C, QSB, and QSL series.

Raw Water Pump Impellers for Cummins 6C

Impellers are wear items that must be replaced periodically to maintain optimal pump performance. Operating in saltwater causes blade wear, hardening, or disintegration over time.

Key Shaft Impeller for Marine Pumps

-

Height: 3 ½”

-

Width: 2 ⅞”

-

Overall Diameter: 3 5/16”

-

Design: Engineered for keyed shaft engagement for Cummins marine water pumps

Splined Shaft Marine Impeller

-

Blade Count: 12 flexible blades

-

Depth: 2 ⅞”

-

Diameter: 3 5/12”

-

Shaft Fitment: Designed for ¾” splined shafts

We recommend inspecting impellers every 200 hours of operation or as part of your seasonal maintenance schedule.

Seals, Gaskets, and Mounting Hardware

Marine Water Pump Mounting Gasket

When replacing a marine water pump, it’s critical to use a fresh gasket to ensure a leak-proof seal at the engine block. Our marine-grade mounting gaskets are designed for heat, vibration, and saltwater resistance.

Water Pump O-Rings

These specialized O-rings seal the inlet and outlet ports of Cummins marine water pumps. We recommend replacing both during any pump or impeller service to avoid hidden leaks.

-

Set Includes: 2 O-rings (one for inlet, one for outlet)

-

Compatibility: Used on QSB, QSC, 6C, 6CT, 6CTA, ISC engines

Heat Exchangers for Cummins 6C Engines

The raw water drawn by the pump cools the internal coolant via a heat exchanger. For systems in need of full rebuilds or upgrades, we carry:

New Marine Heat Exchanger Assembly

Ideal for complete cooling system overhauls or major repairs. Designed for direct fitment to Cummins 6C8.3 and compatible marine engines. Built with corrosion-resistant materials for long service life in seawater environments.

Heat Exchanger Gasket

Ensures a proper seal between the heat exchanger body and connecting components. A 5” diameter interface guarantees fitment with Cummins 6C, 6CT, QSC, and QSL marine engines.

Cummins 6C Marine Thermostats & Gaskets

Maintaining proper operating temperature is vital for performance, fuel economy, and emissions control. Diesel Pro Power offers marine-rated thermostats:

Standard 180°F Thermostat

This is the go-to replacement for most marine 6C applications. It opens at 180°F to allow coolant flow through the heat exchanger once the engine reaches operating temperature.

Vented 180°F Thermostat

Includes a venting mechanism to allow air and gases to escape the system during warm-up, reducing the risk of trapped air pockets and uneven cooling.

Thermostat Gasket

A necessary part when installing any new thermostat, this gasket ensures a tight seal between the thermostat housing and the engine block.

Impeller Puller Tool

Safely removing a marine impeller can be challenging without the right tools. This specialized impeller puller allows you to:

-

Remove stubborn impellers without damaging the blades

-

Avoid bending or breaking the impeller shaft

-

Service your pump efficiently, even in tight quarters

Recommended for both on-board maintenance and workshop repair.

Hose Systems for Cummins Marine Cooling

A network of hoses delivers raw water between the intake, pump, heat exchanger, and exhaust. Diesel Pro Power provides the full hose layout for Cummins 6C installations.

Straight Marine Hoses

Used to connect the pump to the heat exchanger and beyond. Made with reinforced rubber or silicone to handle pressure and temperature fluctuations:

-

Common Sizes: 1”, 1 ¾”, 2”, 2 ½”, 3”, 4”

-

Lengths: Sold in 1-foot increments

Elbow Hose for Tight Bends

Essential when routing sea water from the pump outlet to other system components without kinking:

-

Pre-formed for Cummins 6C, 6CT, and 6CTA engines

-

Connects sea water pump tube to the exhaust or heat exchanger outlet

Silicone Coolant Hoses – Flexible and Durable

Silicone hoses outperform rubber in marine cooling systems due to their high-temperature tolerance and chemical resistance. Ideal for raw water and coolant routing:

Hose Sizes (All 1 Foot Long)

-

1”

-

1 ¾”

-

1 ⅞”

-

2”

-

2 ⅛”

-

2 ¼”

-

2 ⅜”

-

2 ½”

-

2 ¾”

-

3”

-

3 ½”

-

4”

Each hose features reinforced walls to resist collapse and vibration in marine engine bays.

Stainless Steel Hose Clamps for Cummins Cooling Systems

To prevent leaks and secure every cooling line, we offer corrosion-resistant clamps that cover a wide range of diameters:

Available Clamp Ranges

-

Small Clamps: 9/16" to 1-1/16"

-

Medium Clamps: 11/16" to 1-¼", 13/16" to 1-¾"

-

Large Clamps: 1" to 1.5", 1-5/16" to 2-¼", 1-9/16" to 2-½"

Stainless construction ensures longevity in saltwater environments and is safe for both coolant and fuel lines.

Zinc Anodes for Corrosion Protection

Zinc anodes are critical in any raw water cooling system. They serve as sacrificial metal to protect heat exchangers, coolers, and other brass or bronze components from electrolysis.

Zinc for Heat Exchangers

-

Fitment: NPT ½” brass plug

-

Zinc Length: 2”

-

Use: Suitable for Cummins heat exchangers and Detroit Diesel equivalents

Zinc for Fuel and Oil Coolers

-

Fitment: NPT ⅜” brass plug

-

Zinc Length: 1”

Replace zincs regularly—at least once per season or when more than 50% consumed.

Intake Sea Water Strainers for Cummins Marine Cooling

Before seawater enters the pump, it must be filtered. Strainers catch sand, silt, and organic matter that could otherwise clog impellers and restrict flow.

Marine Intake Strainer Options

-

1” Pipe Size: 9 ½” height x 5 ½” width

-

1.5” Pipe Size: 11 ½” height x 7 ¼” width

-

2” Pipe Size: 16” height x 7 ½” width

-

2.5” Pipe Size: 16” height x 7 ½” width

These strainers feature clear inspection covers, corrosion-resistant housings, and replaceable mesh screens for fast maintenance.

Maintenance Tips for Cummins 6C Marine Water Pumps

Keeping your raw water cooling system in top shape is crucial to protecting your Cummins 6C engine. Below are tips to maximize performance and reliability:

-

Flush the System Regularly: Especially after operating in sandy or muddy conditions

-

Inspect the Impeller Every 200 Hours: Look for cracks, hardened blades, or missing material

-

Check Hose Clamps for Rust: Replace any that show signs of pitting or loss of tension

-

Replace Zincs Frequently: Never let them corrode completely—doing so exposes other components to galvanic damage

-

Carry Spares Onboard: Keep at least one impeller, one O-ring set, and a clamp kit on every trip

Applications for Cummins 6C in Marine Vessels

The 6C marine engine has been used globally in various marine platforms due to its consistent power delivery and support for continuous duty cycles:

-

Trawlers and Tuna Boats

-

Tugboats and Tow Vessels

-

Military Rigid Hull Inflatable Boats (RHIBs)

-

Passenger Ferries

-

Workboats and Push Barges

-

Standby Generators on Commercial Ships

Its raw water system must be optimized for consistent cooling performance, especially when engines are under load for long durations.

Why Diesel Pro Power?

With over 40,000 satisfied customers worldwide, Diesel Pro Power is trusted by marine mechanics, fleet managers, and vessel owners for genuine-quality Cummins marine parts. Every component listed in this catalog is carefully selected for its durability, fitment, and performance in real-world marine conditions.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588