Marine CAT 3116 Coolant System Specific Component Maintenance Life

Please note that these are typical maintenance intervals for the Marine CAT 3116 engine’s coolant system components, and some results may vary based on operating conditions. Adhering to these schedules is essential for ensuring reliable performance and extending the engine’s operational life.

Component |

Maintenance Interval (Hours) |

Notes |

| Coolant | 1,000 hours | Change to maintain optimal cooling and prevent corrosion in the system. |

| Freshwater Pump | 2,000-3,000 hours | Inspect for leaks, wear, and corrosion; replace seals or rebuild as necessary. |

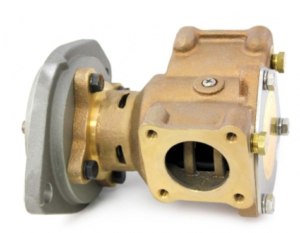

| Raw Water Pump | 500-1,000 hours | Inspect impeller for wear; replace impeller and seals as needed to maintain proper cooling. |

| Thermostats | 1,500-2,000 hours | Inspect and test; replace if malfunctioning or during major coolant system service. |

Maintaining these components according to the recommended intervals is crucial for the reliable operation of the CAT 3116 engine, particularly in marine environments. Regular inspections and timely servicing help extend the engine’s life and minimize the risk of unexpected failures.

Disclaimer: The most accurate data for each specific engine will always be found in the OEM service manual. The numbers provided here are estimates and can vary based on operating conditions. Factors such as inadequate cooling, lubrication, or fuel quality issues can affect other engine components, potentially altering maintenance intervals. Engine components are interconnected, so one issue can impact others, leading to different service needs. Always tailor your maintenance approach to the specific conditions in which your engine operates.

Engine Specifications & Applications of the Caterpillar 3116 Engine

Introduction to the Caterpillar 3116 Engine

The Caterpillar 3116 is a highly versatile inline six-cylinder diesel engine designed for use in a wide range of on-highway, industrial, construction, and marine applications. First introduced in the late 1980s, the 3116 engine helped set the standard for mid-range diesel performance through the 1990s and early 2000s.

While the 3116 was phased out in favor of electronically controlled successors like the 3126 and C7, it remains a highly supported and popular engine in the aftermarket due to its robust mechanical foundation and broad application base. Whether you’re rebuilding a marine propulsion system, maintaining a fleet of older Cat equipment, or servicing a generator, the 3116 continues to be a trusted powerplant with excellent parts availability.

Diesel Pro Power supports the Caterpillar 3116 with a full line of aftermarket components, including cylinder heads, turbochargers, injectors, rebuild kits, water pumps, and more—engineered for performance and longevity in demanding environments.

Caterpillar 3116 Engine Technical Specifications

Base Engine Configuration

|

Specification |

Detail |

|

Engine Model |

Caterpillar 3116 |

|

Engine Type |

4-Stroke Inline 6-Cylinder Diesel |

|

Displacement |

6.6 Liters (403 cubic inches) |

|

Bore x Stroke |

105 mm x 127 mm (4.13″ x 5.0″) |

|

Compression Ratio |

16.5:1 to 18.5:1 (varies by build) |

|

Aspiration |

Turbocharged (intercooled in some models) |

|

Fuel System |

Mechanical Unit Injection (MUI) |

|

Valvetrain |

Overhead Valve, 2 valves per cylinder |

|

Cooling System |

Water-Cooled |

|

Dry Weight |

Approx. 1,450–1,550 lbs (model-dependent) |

|

Flywheel Rotation |

Counterclockwise (viewed from flywheel) |

Power & Torque Ratings

|

Configuration |

Output Range |

|

Industrial/Construction |

170 – 250 HP @ 2,200 – 2,400 RPM |

|

Marine Propulsion |

205 – 350 HP (continuous or intermittent duty) |

|

On-Highway (Truck) |

170 – 300 HP @ 2,200 RPM |

|

Max Torque |

Up to 860 lb-ft @ 1,440 – 1,600 RPM |

These figures vary by application (marine, industrial, or vehicle), turbocharging setup, and emissions tier. The marine versions often run at lower continuous duty RPMs, while industrial and truck variants emphasize torque delivery and fuel economy.

Caterpillar 3116 Engine Variants

The Caterpillar 3116 is available in multiple configurations, optimized for specific market segments:

-

3116 DITA (Direct Injection Turbocharged Aftercooled): Found in marine, truck, and generator setups requiring greater power density.

-

Naturally Aspirated and Turbocharged Industrial Models: Used in mid-size equipment and generators.

-

Marine Propulsion Versions: High-output continuous or intermittent duty versions rated up to 350 HP.

While all 3116 engines share a common block and core design, components like the turbocharger, injection timing, and cooling systems differ between applications. Diesel Pro Power offers parts cataloged by engine serial number prefix to ensure proper fitment across all variants.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588