Marine engines in the Detroit Diesel V71 series (6V71, 8V71, 12V71, and 16V71) require robust raw water pumps to meet the demanding cooling requirements of marine environments. These pumps are critical components of the cooling system, responsible for drawing in external water (seawater or freshwater) to facilitate heat dissipation. Unlike standard water pumps, raw water pumps are specifically engineered to handle the challenges posed by marine conditions, such as debris, sand, and corrosive elements.

Marine Cooling System & Related Components for Detroit Diesel 12V71Turbo Marine & Industrial Engines

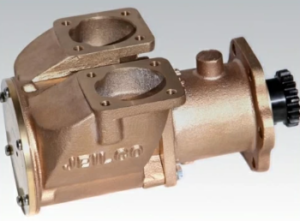

Design and Functionality of the Raw Water Pump for Detroit Diesel V71 Engines

Flexible Impeller Design

One of the defining features of raw water pumps for Detroit Diesel V71 engines is their flexible rubber impellers:

- Adaptability: The flexible impeller can deform as it rotates, allowing it to pump water effectively even in the presence of small debris like sand or organic matter.

- Self-Priming Capability: Flexible impeller pumps can self-prime, making them ideal for marine applications where water intake may vary.

- Wear Considerations: While the impeller’s flexibility helps prevent jamming, it also makes the component prone to wear, particularly if it operates dry or encounters abrasive materials.

Corrosion-Resistant Materials

Marine raw water pumps are constructed from materials designed to withstand exposure to saltwater and other corrosive elements:

- Bronze and Stainless Steel: Commonly used for pump housings and components due to their excellent resistance to corrosion and durability.

- Rubber or Neoprene Impellers: These materials offer flexibility and resistance to wear but require regular inspection to maintain optimal performance.

Internal Seals and Bearings

- Raw water pumps include high-quality seals and bearings to prevent leaks and ensure smooth operation. These components are designed to resist the corrosive effects of saltwater and the wear caused by continuous operation.

Operation in the Cooling System

Raw water pumps in marine Detroit Diesel V71 engines play a pivotal role in the heat exchanger cooling system:

- Water Intake: The pump draws in raw water from the surrounding environment through an intake system that includes strainers to filter out large debris.

- Flow Through the Heat Exchanger: The raw water circulates through the heat exchanger, where it absorbs heat from the engine coolant without direct contact.

- Discharge: After transferring heat, the warmed raw water is expelled overboard, completing the cycle.

This continuous flow of raw water ensures that the engine operates within safe temperature limits, even under heavy loads.

Common Issues and Failures for Raw Water Pumps In Detroit Diesel V71 Engines

Raw water pumps are subject to specific challenges and potential failures due to their operating conditions:

1. Impeller Damage

- Causes:

- Running the pump dry for extended periods can cause the rubber impeller to overheat and degrade.

- Abrasive materials such as sand or grit can erode the impeller blades over time.

- Symptoms:

- Reduced water flow or complete loss of pumping action.

- Overheating of the engine due to insufficient cooling.

- Solutions:

- Inspect the impeller regularly and replace it if cracks, wear, or missing blades are detected.

- Avoid running the pump without water to prevent dry operation.

2. Clogged Intake Screens

- Causes:

- Accumulation of debris such as seaweed, plastic, or small marine organisms in the intake system.

- Accumulation of debris such as seaweed, plastic, or small marine organisms in the intake system.

- Symptoms:

- Reduced water flow to the pump.

- Higher operating temperatures or engine alarms.

- Solutions:

- Clean the intake screens regularly to prevent blockages.

- Ensure strainers are in place and in good condition to filter incoming water.

3. Corrosion

- Causes:

- Continuous exposure to saltwater can corrode the pump housing, seals, and other metal components.

- Continuous exposure to saltwater can corrode the pump housing, seals, and other metal components.

- Symptoms:

- Visible rust or pitting on the pump housing.

- Leaks at the pump seals.

- Solutions:

- Use corrosion-resistant materials such as bronze or stainless steel for replacements.

- Flush the system with freshwater after operating in saltwater environments to minimize corrosion.

4. Seal and Bearing Wear

- Causes:

- Prolonged use or exposure to abrasive particles can degrade seals and bearings.

- Prolonged use or exposure to abrasive particles can degrade seals and bearings.

- Symptoms:

- Leaks around the pump housing.

- Noisy operation or increased vibration.

- Solutions:

- Inspect seals and bearings during routine maintenance and replace them as necessary.

- Inspect seals and bearings during routine maintenance and replace them as necessary.

Maintenance Practices for Detroit Diesel V71 Engines

Proper maintenance of raw water pumps is crucial for the reliable operation of Detroit Diesel V71 marine engines:

1. Regular Impeller Inspection and Replacement

- Frequency: Inspect impellers every 250–500 hours of operation or at least once per season.

- Replacement Tips:

- Always carry a spare impeller to minimize downtime during unexpected failures.

- Use impellers made of high-quality rubber or neoprene compatible with the pump model.

2. Cleaning the Intake System

- Steps:

- Remove and clean the intake screens and strainers to ensure unobstructed water flow.

- Inspect the intake hose for cracks or obstructions and replace it if damaged.

3. Flushing the Pump

- Why: Flushing removes salt and other deposits that can accelerate corrosion or clog the pump.

- How:

- Use freshwater to flush the pump after each use in saltwater environments.

- Introduce a mild cleaning solution periodically to remove scaling.

4. Inspecting Housing and Seals

- Check the pump housing for signs of corrosion, cracks, or leaks.

- Replace seals and gaskets during impeller replacements or if leaks are detected.

5. Monitoring Water Flow

- Use flow meters or visual inspections to ensure the pump delivers sufficient water volume.

- Investigate any reduction in flow immediately to prevent engine overheating.

Upgrading Raw Water Pumps

For marine applications that demand higher performance or increased durability, upgrading the raw water pump can provide significant benefits:

High-Performance Impellers

- Enhanced materials and designs increase resistance to wear and improve pumping efficiency.

Advanced Seal Technology

- Modern seals offer superior protection against leaks and corrosion, extending the lifespan of the pump.

Digital Monitoring Systems

- Sensors can monitor water flow, pressure, and pump performance, alerting operators to potential issues before they escalate.

Environmental Considerations

The operating environment significantly impacts the maintenance and performance of raw water pumps:

Saltwater Applications

- Saltwater is highly corrosive and requires pumps made from premium corrosion-resistant materials.

- Regular flushing with freshwater is critical to prolong pump life.

Freshwater Applications

- While less corrosive, freshwater can still carry debris and contaminants that affect pump performance.

- Inspect intake strainers frequently to remove obstructions.

High-Debris Environments

- Operating in debris-heavy areas, such as rivers or harbors, increases the risk of clogging.

- Install high-capacity strainers to filter larger particles effectively.

Summary and Recommendations for Raw Water Pumps In Detroit Diesel V71 Engines

The raw water pump is a cornerstone of the cooling system in Detroit Diesel V71 marine engines, ensuring efficient heat management in challenging operating environments. Regular maintenance and prompt replacement of worn components are essential to prevent costly engine failures and downtime. By understanding the unique design, functionality, and maintenance requirements of raw water pumps, operators can maximize the reliability and efficiency of their Detroit Diesel V71 engines.

Key Takeaways:

- Inspect and replace impellers regularly to maintain optimal water flow.

- Clean intake strainers frequently to prevent blockages and maintain pump efficiency.

- Use corrosion-resistant materials and flush the system with freshwater to protect against saltwater damage.

- Monitor water flow and pump performance to identify and address issues early.

Marine Cooling System & Related Components for Detroit Diesel 12V71Turbo Marine & Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588