Parts for Detroit Diesel 6V71 Non-Turbo - Marine Water Pump Section

Loading...

Loading... -

Marine Water Pump for Detroit Diesel 53 & 71 Series Marine Engines

5145578

Bidirectional Pump (It Turns Right or Left)

Port Type: 1” Flange. Includes Drive Gear and Mounting Adapter

Price: $ 802.29 -

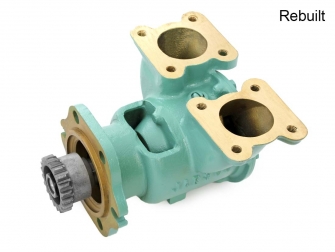

Marine Water Pump for Detroit Diesel 53, 71 and 92 Series Marine Engines, Rebuilt

23507971R

Sold with refundable core deposit. See details

Bidirectional Pump (It Turns Right or Left)

Port Type: 1 1/2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 2 1/2”

Price: $ 892.00 -

Marine Water Pump for Detroit Diesel 53, 71 and 92 Series Marine Engines

23507971

Bidirectional Pump (It Turns Right or Left)

Port Type: 1 1/2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 2 1/2”

Price: $ 1,068.69 -

Impeller for Caterpillar, Detroit Diesel, and Volvo Penta Marine Water Pumps

8924838

Impeller with 12 Blades and 12 Spline Drive.

Diameter: 3 3/4” - Height: 2 1/2”

Price: $ 96.73 -

Detroit Diesel Marine Water Pump repair kit 6V53, 6V71, 6-71, 6V92

5197224P

For 2 1/2" impeller height

Price: $ 630.32 -

Detroit Diesel Gasket, Marine Water Pump

5115395

Each pump uses 2 of this gasket. Water inlet and outletPrice: $ 4.38 -

-

Impeller for Detroit Diesel and Volvo Penta Marine Water Pumps

5193602

Impeller with 10 Blades and 12 Spline Drive.

Diameter: 2 1/2” - Height: 2”

Price: $ 58.76 -

Seal for Detroit Diesel Marine Water Pump

5199150

used with raw water pump with 1" water inlet, outlet port that has a 2" impeller

Price: $ 106.55 -

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Heat Exchanger Gasket Kit for Marine Engines for Series 53, 71 and 92

5192637

.Price: $ 97.18 -

-

-

-

-

-

Zinc for Marine Engine - for Heat Exchangers

E4C

Brass plug NPT 3/4", zinc length 3 3/8"Price: $ 33.43 -

Zinc for Marine Engine - for Marine Water Pumps

E3C

Brass plug NPT 3/4", zinc length 2"Price: $ 32.05 -

Zinc for Marine Engine - for Marine Water Pumps

E2C

For Detroit heat exchanger For Cummins heat exchanger and aftercooler For Brass plug NPT 1/2", zinc length 2"Price: $ 27.53 -

Zinc for Marine Engine - for Fuel Coolers & Oil Coolers

E1C

Brass plug NPT 3/8", zinc length 2"Price: $ 24.54 -

Zinc for Marine Engine - for Fuel Coolers & Oil Coolers

E00

Brass plug NPT 1/8", zinc length 2"Price: $ 18.72 -

Detroit Diesel Cam for Marine Water Pump or Marine Water Pump

5193554

For 2 1/2" dia raw water pump

Price: $ 168.90 -

-

Detroit Diesel Cover for Marine Water Pump with 2 1/2 and 3 1/2 inch dia impeller

5193555

For 2 1/2" and 3 1/2 impeller

Price: $ 94.00 -

-

-

-

-

-

-

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 16.50 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 16.68 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 17.19 -

-

Controls Cables & More...

-

Marine Control

-

Industrial Cable

-

Marine Cables 1/16 thread

-

Marine Cables 1/4 thread

-

Marine Steering

-

Rubber Bearing

-

Searchlight

-

Marine Bulb

-

Navigation Light

-

Parts for Detroit Diesel 6V71 Non-Turbo – Marine Water Pump Section

Overview of the 6V71 Marine Cooling System

The Detroit Diesel 6V71 Non-Turbo engine has long been one of the most reliable and respected power sources in the marine industry. Known for its rugged construction and two-stroke design, it’s often found powering commercial vessels, fishing boats, and workboats that require dependable cooling in harsh marine environments. The raw water pump—often called the marine water pump—is the heart of this engine’s cooling system. Its job is to draw seawater from outside the hull, push it through the heat exchanger and oil cooler, and then discharge it overboard after it absorbs engine heat.

When the raw water pump starts to wear out, you may notice rising engine temperatures, leaking seals, or reduced water flow. These signs mean it’s time for a rebuild or replacement. The parts below are all designed specifically for the Detroit Diesel 6V71 Non-Turbo engine, ensuring the proper flow rate, impeller fit, and mounting alignment that this classic engine requires.

Marine Water Pumps for Detroit Diesel 6V71 Non-Turbo

Diesel Pro Power offers both new and rebuilt marine water pumps designed to deliver consistent performance under demanding marine conditions.

New Raw Water Pump for Detroit Diesel 6V71 Non-Turbo

Our brand-new pump includes a 1-inch flange, drive gear, and mounting adapter. The bronze housing and stainless-steel shaft resist corrosion, while the heavy-duty bearings and seals ensure long-term durability. The pump’s bidirectional design allows operation on either rotation, making installation simple no matter your engine configuration.

Rebuilt Raw Water Pump for Detroit Diesel 6V71 Non-Turbo

For those seeking an affordable option without compromising quality, Diesel Pro Power’s rebuilt pumps offer factory-level performance. Each unit is completely remanufactured with new bearings, seals, and an impeller before being flow-tested and inspected. A refundable core deposit is offered, so you can return your old unit for credit.

Impellers and Pump Repair Kits

Impeller for Detroit Diesel 6V71 Non-Turbo Marine Water Pump

A worn impeller is one of the most common causes of engine overheating. Diesel Pro Power’s 12-blade neoprene impeller features a 12-spline drive for perfect fitment in the 6V71 pump housing. With a diameter of 3¾ inches and height of 2½ inches, it restores full pumping efficiency.

Marine Water Pump Repair Kit for Detroit Diesel 6V71 Non-Turbo

If you prefer to rebuild rather than replace, this comprehensive repair kit includes every seal, gasket, and bearing needed to restore full function. Designed for 2½-inch impeller pumps, it helps extend the life of your existing housing and restore factory flow.

Gaskets, Seals, and Bearings

To maintain proper pressure and prevent leaks, high-quality gaskets and seals are essential.

Marine Water Pump Gaskets

Each 6V71 pump uses two gaskets for the inlet and outlet, along with a mounting gasket for the adapter plate. Additional gaskets are available for the pump cover, flywheel connection, and plate assembly.

Seals and Bearings

Diesel Pro Power’s mechanical seals prevent seawater from entering the bearing housing, while the shaft seal and bearing oil seal protect against lubricant loss. Precision ball bearings ensure smooth, vibration-free operation. Replacing these components together during a rebuild ensures optimal performance and longevity.

Thermostats and Temperature Control

Maintaining proper temperature is critical for the 6V71 Non-Turbo engine’s efficiency and longevity.

Thermostats for Detroit Diesel 6V71 Non-Turbo

Available in both 160°F and 170°F ratings, these thermostats allow precise control of coolant temperature for different operating conditions. A new thermostat seal ensures a perfect fit and prevents coolant leaks.

Heat Exchangers and Related Components

The heat exchanger acts as the bridge between seawater and the closed-circuit coolant system, ensuring the engine maintains safe operating temperatures.

Heat Exchanger Core

Built from copper-nickel tubing, the core efficiently transfers heat while resisting corrosion.

Heat Exchanger Gasket Kit

Includes all necessary gaskets for sealing the housing during maintenance.

Glands, Seals, and Radiator Gaskets

The gland and seal components prevent leaks from the marine engine tank. Radiator gaskets are available in both standard and small sizes to ensure a perfect seal during reassembly.

Zinc Anodes for Corrosion Protection

Saltwater corrosion is an inevitable part of marine operation, but zinc anodes protect critical components from electrolysis damage.

Zincs for Detroit Diesel 6V71 Non-Turbo Marine Systems

Replace zincs at least once a year or whenever more than half of the material is depleted. This simple maintenance step helps extend the lifespan of your entire cooling system.

Hardware, Covers, and Wear Plates

Cam, Wear Plate, and Cover Assemblies

The pump cam and wear plate ensure efficient water movement inside the housing, while the stainless-steel cover prevents leaks. Regular inspection of these parts maintains proper water pressure.

Cover Screws and Mounting Hardware

Each pump cover plate uses five stainless-steel screws. These screws resist corrosion and maintain consistent sealing pressure over time.

Paint, Hoses, and Clamps

Detroit Diesel Green Paint

Protects your engine against rust while maintaining the factory-correct Detroit Diesel green finish. The paint is resistant to oil, heat, and salt spray.

Silicone Coolant Hoses

Available in sizes from 1” to 4” inside diameter, these hoses resist heat, oil, and vibration far better than traditional rubber. Perfect for replacing worn coolant lines in your 6V71.

Hose Clamps

Stainless-steel clamps provide secure, leak-free connections. Each clamp includes size specifications to ensure proper fit.

Monitoring and Maintenance Tips

Mechanical and Electrical Gauges

Diesel Pro Power offers both mechanical and electric gauges (12V and 24V) to monitor engine temperature and water pressure. Early detection of low flow or overheating helps prevent major failures.

Maintenance Tips for 6V71 Raw Water Pumps

-

Inspect impellers every 250 hours of operation.

-

Flush the cooling system with fresh water after each saltwater use.

-

Replace zinc anodes regularly to prevent corrosion.

-

Check seals for signs of leaking or salt buildup.

-

Repaint exposed pump surfaces to prevent oxidation.

Proper care and regular inspection will keep your Detroit Diesel 6V71 Non-Turbo engine operating reliably for decades.

Why Buy Your Detroit Diesel 6V71 Non-Turbo Raw Water Pump from Diesel Pro Power

Diesel Pro Power is the world’s most trusted source for Detroit Diesel 6V71 Non-Turbo parts. We’re more than a parts supplier—we’re your partner in marine engine reliability. With over 40,000 satisfied customers worldwide, we have earned the trust of boat owners, fleets, and shipyards that rely on Detroit Diesel engines every day.

Here’s why customers continue to choose Diesel Pro Power:

-

All-in-one source: Every gasket, impeller, and seal for your 6V71 Non-Turbo marine cooling system is available in one place.

-

In-stock and ready to ship: All products are kept in stock for fast worldwide delivery with real-time tracking.

-

Expert guidance: Our Detroit Diesel-trained technicians can help you confirm fitment and installation details.

-

OEM-quality standards: All components meet or exceed Detroit Diesel’s marine specifications.

-

Proven reputation: Thousands of commercial, military, and private vessels depend on our products for daily operation.

Whether you’re overhauling your cooling system or performing preventive maintenance, Diesel Pro Power provides the dependable quality and support that keeps your Detroit Diesel 6V71 Non-Turbo running strong.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588