Introduction

When working on high-torque, hydraulic marine transmissions like the Twin Disc MG516 and MG5161, safety is more than a checklist—it’s a critical part of every maintenance, repair, and inspection process. Whether you’re performing a routine oil change or doing a full transmission rebuild, the risks range from oil injection injuries to crushed fingers or unexpected clutch engagement. This section outlines the most important safety precautions, lockout/tagout (LOTO) steps, required personal protective equipment (PPE), and the complete toolkit you need to safely and effectively maintain or service the MG516.

Disclaimer: For more technical instructions and torque specifications, always refer to the OEM service manual. This guide is meant to supplement—not replace—OEM recommendations and safety protocols.

Parts Catalog for Twin Disc MG516 Marine Transmissions

Rebuilt Twin Disc MG516 Marine Transmissions

Plate Kit For Twin Disc MG516 Marine Transmission

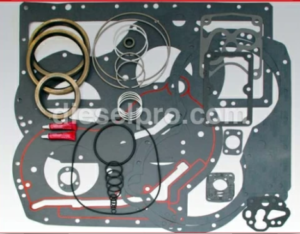

Gasket Kits For Twin Disc MG516 Marine Transmission

Personal Protective Equipment (PPE) for Twin Disc MG516 Marine Gear Maintenance

Proper PPE is your first and best defense when working in and around marine transmission systems. Hydraulic fluid under pressure, rotating shafts, hot components, and electrical interfaces can all pose serious injury risks.

Essential PPE Items

Below is a list of essential personal protective equipment required for servicing the Twin Disc MG516:

- Safety Glasses or Goggles

To protect against hydraulic fluid spray, debris, and splashed oil during filter changes, pressure tests, and disassembly.

- Steel-Toe Boots

Prevent foot injuries from dropped tools, flywheels, or housings—especially important when removing the transmission from the engine bed.

- Mechanic’s Gloves (Oil-Resistant)

Protect hands from sharp edges, metal burrs, and hot components while maintaining grip on oily surfaces.

- Face Shield (During Pressure Testing or Grinding)

For operations involving grinders, presses, or pressure diagnostics, use a full-face shield to protect from burst hoses or flying particles.

- Hearing Protection

In engine rooms or shipboard environments where dB levels exceed safe limits, earplugs or earmuffs are essential.

- Protective Overalls or Fire-Retardant Clothing

Reduce the risk of clothing entanglement and protect skin from hot fluid contact and oil soaking.

- Knee Pads or Anti-Fatigue Mats

Important during under-hull or confined-area work common in marine engine rooms.

Inspection and Maintenance of PPE

- Inspect gloves and goggles before every job for tears or clouded vision.

- Clean PPE with appropriate degreasers after use to remove flammable oil residues.

- Replace worn or damaged PPE immediately—do not improvise or reuse compromised equipment.

Lockout/Tagout (LOTO) Procedures for Twin Disc MG516 Marine Gear

Lockout/tagout is a formal safety procedure to prevent the accidental start-up or energizing of equipment during maintenance. Skipping this step can result in crushed limbs, amputations, or fatalities, especially when dealing with hydraulic pressure and rotating shafts.

Why LOTO Is Critical for Marine Gears

- Hydraulic systems retain pressure even when the engine is shut down.

- Transmission components like clutches can engage if power is restored unexpectedly.

- Cooling systems may activate automatically, creating slip or burn hazards.

- Diesel engines can restart from remote locations if not properly locked out.

Step-by-Step Lockout/Tagout Procedure

- Shut Down Engine

- Use the primary engine stop button or shutdown procedure specific to your vessel.

- Confirm that the engine has come to a complete stop.

- Turn Off Transmission Control Systems

- Shut down all electronic control systems (such as the EC300).

- Disconnect mechanical shift linkages if applicable.

- Isolate Power Sources

- Lock out the main battery switch or breaker panel that feeds the transmission control system.

- Apply lockout tags on both the electrical panel and shift control levers.

- Release Hydraulic Pressure

- Manually depressurize the hydraulic system using the pressure relief port (if equipped).

- Use a test gauge to verify that system pressure is at zero PSI.

- Secure Drive Shaft or Output Flange

- Lock the output flange using shaft restraints or install a custom flange bracket to prevent rotation.

- Lock the output flange using shaft restraints or install a custom flange bracket to prevent rotation.

- Apply Lockout Devices

- Use industry-rated padlocks and tags with technician names, time/date, and scope of work clearly indicated.

- Use industry-rated padlocks and tags with technician names, time/date, and scope of work clearly indicated.

- Attempt Restart Test

- Try to start the engine and shift the transmission. If the system doesn’t activate, your lockout is confirmed.

- Try to start the engine and shift the transmission. If the system doesn’t activate, your lockout is confirmed.

- Begin Work Only After Verification

- Verify with a second technician or supervisor that all energy sources are locked out and the system is fully de-energized.

- Verify with a second technician or supervisor that all energy sources are locked out and the system is fully de-energized.

Pro Tip: Use a LOTO checklist taped inside your tool chest to ensure nothing is missed.

Recommended Tools for Twin Disc MG516 Marine Gear Service

Technican uses a torque wrench

Servicing the MG516 transmission requires a specialized mix of mechanical, hydraulic, and diagnostic tools. Below is a breakdown by category to help you build or audit your transmission service toolkit.

Basic Hand Tools

These are required for most service tasks, including oil changes, cooler inspections, and filter replacements.

- Socket Set (Metric & SAE): 3/8” and 1/2” drive sets ranging from 8mm to 32mm

- Box-End and Combination Wrenches: For use in confined engine compartments

- Torque Wrench (0–250 ft-lbs): Essential for proper clutch cover and housing torques

- Breaker Bar (24”): For removing stubborn flange bolts

- Allen/Hex Key Set: Required for internal hydraulic control screws

- Pry Bars and Scrapers: Useful for removing old gaskets and sealant

- Ratchet Extensions and Universal Joints: For hard-to-reach mounting bolts

- Adjustable Wrench: Always a backup when custom fittings are present

- Needle Nose Pliers and Snap Ring Pliers: For seals, washers, and clutch ring handling

Hydraulic Service Tools

- Hydraulic Pressure Test Kit: Should include gauge (0–500 PSI), hoses, and T-fitting

- Hydraulic Line Plug Kit: For temporarily blocking oil lines during disassembly

- Oil Filter Wrench: Correct size for MG516 transmission filter

- Fluid Transfer Pump: Manual or electric, for draining and filling transmission oil

- Hydraulic Oil Catch Pan (20+ quart): With built-in splash guard

Diagnostic Tools

- Infrared Thermometer: For checking operating temperature of transmission housing

- Borescope or Inspection Camera: Useful for viewing clutch packs and gear teeth through access ports

- Dial Indicator with Magnetic Base: For measuring shaft runout and flange alignment

- Stethoscope for Mechanics: Helps identify internal noise from gears or bearings

- Multimeter: For verifying voltage to solenoids or control panels

Heavy Lifting and Support Tools

- Transmission Jack or Hydraulic Engine Hoist: For removing or reinstalling the MG516 safely

- Sling and Load Leveler Kit: For balancing transmission weight during removal

- Engine Room Crane or Gantry System: Recommended for heavy units like the MG516

- Safety Blocks or Wooden Shims: To prevent rolling or crushing hazards during work

Seal and Gasket Tools

Gasket and seal kit for Twin Disc marine transmission MG516.

- Seal Driver Set: For installing input and output shaft seals without damage

- Bearing Pullers: For removing stuck bearings during rebuilds

- Gasket Punch Set: For custom gasket fabrication if OEM gaskets are unavailable

- Thread Chaser Kit: For restoring bolt hole integrity

Cleaning and Preparation Supplies

- Non-Chlorinated Brake Cleaner: Safe for degreasing transmission housings

- Parts Washer or Ultrasonic Cleaner: For cleaning reusable components

- Lint-Free Rags and Shop Towels: Prevent debris contamination

- Sealant and RTV: Marine-rated, oil-resistant formula

- Anti-Seize Compound: For use on mounting hardware

- Thread Locker (Blue or Red): For vibration-prone fasteners

Tool Storage and Maintenance

Just having the tools isn’t enough—they need to be stored and maintained properly to ensure safety and accuracy.

- Use foam-lined drawer organizers to keep tools from shifting during transit

- Label all sockets and bits by size for quick identification

- Calibrate torque wrenches annually or after suspected misuse

- Check seals on hydraulic gauges for leaks or wear before each use

- Sharpen or replace dull scrapers and cutters to prevent slips

Shop Setup Recommendations

When working in a commercial or independent marine shop, how you set up your workspace can affect both safety and efficiency.

- Clear Floor Space: Minimum 6×6 feet open around transmission for safe lifting

- Non-Skid Mats: Underfoot safety for standing on oily surfaces

- Wall-Mounted Tool Racks: Easy access and faster turnaround times

- Compressed Air Supply: With blow gun and oil-safe fittings

- Overhead Lighting or Headlamp: Good visibility is non-negotiable

- Fire Extinguisher Nearby: Oil fires are a risk in marine engine work

- Spill Containment Kits: For immediate cleanup of oil or coolant spills

What Not to Use

Avoid these common mistakes that could compromise safety or damage the MG516 transmission:

- Impact Guns for Torque-Sensitive Bolts: Can warp housings or strip threads

- Pipe Wrenches on Precision Shafts: May damage surfaces and compromise seal integrity

- Detergent Oils or ATF: Not compatible with MG516 clutch materials

- Steel Brushes on Gasket Surfaces: Can cause micro-scoring and leaks

Summary: Safety and Tooling for MG516 Work Done Right

Servicing the Twin Disc MG516 Marine Gear is no job for the underprepared. These transmissions are complex, powerful, and essential to the functioning of commercial vessels. Having the right PPE, following lockout/tagout protocols, and using the correct tools is not just a matter of professionalism—it’s a matter of safety and mechanical integrity.

By investing in quality tools and sticking to consistent safety procedures, you’ll not only extend the life of the MG516, but also protect yourself and your team from preventable accidents. Whether you’re a shipyard technician, independent marine mechanic, or fleet maintenance supervisor, make safety your first tool—and precision your second.

Rebuilt Twin Disc MG516 Marine Transmissions

Plate Kit For Twin Disc MG516 Marine Transmission

Gasket Kits For Twin Disc MG516 Marine Transmission

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588