Proper storage and long-term maintenance are essential for preserving the performance, reliability, and longevity of Cummins B Series engines when they are not in use for an extended period. Whether you are storing a spare engine, winterizing a marine engine, or parking equipment for seasonal downtime, taking the right precautions will prevent corrosion, internal damage, and operational issues when the engine is brought back into service.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

This guide covers:

✔ Best practices for storing a Cummins B Series engine.

✔ How to prevent corrosion, fuel degradation, and moisture buildup.

✔ Preparing the engine for long periods of inactivity.

By following these storage and maintenance guidelines, you can ensure that your Cummins engine remains ready for operation with minimal risk of failure when it is reactivated.

Best Practices for Storing a Cummins B Series Engine

Whether the engine is being stored for a few months or several years, proper storage techniques prevent rust, oil degradation, and fuel system issues. The following steps will ensure the engine remains in peak condition during storage.

1. Choose a Suitable Storage Location

✔ Keep the engine in a dry, climate-controlled environment whenever possible.

✔ Avoid direct exposure to moisture, extreme temperatures, and humidity, which can lead to condensation buildup.

✔ If outdoor storage is necessary, use a high-quality tarp or engine cover to protect against rain, snow, and UV damage.

✔ For marine engines, consider flushing the cooling system and storing the engine in a well-ventilated area to prevent salt buildup.

✔ Proper storage location reduces the risk of corrosion, component wear, and environmental damage.

2. Clean the Engine Before Storage

✔ Remove all dirt, grease, and grime from the engine exterior.

✔ Degrease the engine block and components using an appropriate cleaner.

✔ Clean the air intake system and exhaust manifold to remove dust and carbon buildup.

✔ Flush the cooling system to prevent scale and rust from forming in the radiator and passages.

✔ Drain and clean the fuel system (or stabilize the fuel, depending on storage duration).

✔ A clean engine prevents contamination and makes post-storage reactivation easier.

3. Drain or Stabilize the Fuel System

Diesel fuel degrades over time, leading to clogged fuel injectors, gelling, and microbial growth (algae in fuel tanks). Proper fuel storage procedures help prevent fuel system damage and hard starting when the engine is reactivated.

✔ For short-term storage (less than 6 months):

- Fill the fuel tank completely to reduce condensation and microbial growth.

- Add a diesel fuel stabilizer to prevent fuel oxidation and breakdown.

✔ For long-term storage (6 months or more):

- Drain the fuel tank and fuel lines completely to prevent varnish and sludge buildup.

- Run the engine until fuel lines and injectors are empty to avoid injector clogging.

✔ A properly stored fuel system prevents injector fouling and starting issues after storage.

Fuel Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Injector & Related Components for Cummins 4B Marine & Industrial Engines

Injector & Related Components for Cummins 4BT Marine & Industrial Engines

Injector & Related Components for Cummins 4BTA Marine & Industrial Engines

Injector & Related Components for Cummins 6B Marine & Industrial Engines

Injector & Related Components for Cummins 6BT Marine & Industrial Engines

Injector & Related Components for Cummins 6BTA Marine & Industrial Engines

4. Change the Engine Oil and Filter

Leaving old or contaminated oil in the engine during storage can lead to acidic buildup, sludge formation, and internal corrosion.

✔ Drain and replace engine oil with fresh, high-quality diesel oil.

✔ Use the recommended oil viscosity for storage conditions (e.g., heavier oil for extreme cold).

✔ Replace the oil filter to ensure clean lubrication when restarting the engine.

✔ Run the engine briefly after the oil change to distribute fresh oil through all internal components.

✔ Fresh oil prevents corrosion and ensures proper lubrication upon startup.

Oil Pump & Related Components for Cummins 4B Marine and Industrial Engines

Oil Pump & Related Components for Cummins 4BT Marine and Industrial Engines

Oil Pump & Related Components for Cummins 4BTA Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6B Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6BT Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6BTA Marine and Industrial Engines

5. Protect the Cooling System

Coolant breakdown or contamination can lead to internal corrosion and blockages in the cooling system.

✔ Flush and refill the cooling system with fresh antifreeze before long-term storage.

✔ Use a high-quality coolant that meets Cummins specifications to prevent rust and scale formation.

✔ For marine engines, flush with fresh water and use a corrosion inhibitor to protect the system.

✔ Ensure all hoses and seals are intact to prevent leaks and cracking over time.

✔ Maintaining the cooling system prevents overheating and internal rust formation.

Fresh Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

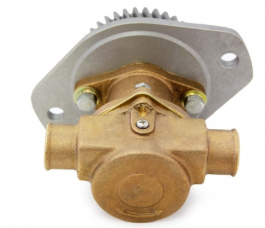

Marine Raw Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

6. Lubricate Critical Engine Components

Engines that sit unused for extended periods can suffer from dry seals, sticking valves, and surface rust on key components.

✔ Fogging Oil Treatment: Spray fogging oil into the intake manifold and cylinders to coat internal parts with a protective film.

✔ Turn the crankshaft by hand periodically to distribute oil and prevent parts from seizing.

✔ Grease moving external components such as throttle linkages, turbocharger actuators, and belt pulleys.

✔ Proper lubrication prevents corrosion and component seizure during storage.

7. Protect the Battery and Electrical System

A battery left unmaintained during long-term storage can lose charge, develop sulfation, or fail completely.

✔ Disconnect and remove the battery if the engine will be stored for more than 3 months.

✔ Store the battery in a dry, temperature-controlled area away from direct heat or cold.

✔ Use a battery maintainer (trickle charger) to keep the battery charged.

✔ Inspect and clean electrical connections to prevent corrosion.

✔ A properly maintained battery ensures the engine starts reliably when brought back into service.

Starter & Alternator Related Components for Cummins 4B Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 4BT Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 4BTA Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6B Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6BT Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6BTA Marine & Industrial Engines

8. Seal Openings to Prevent Contamination

Engines stored for long periods can attract dust, insects, rodents, and moisture, which can cause damage to internal components.

✔ Seal the intake and exhaust openings with plastic covers or rags to prevent debris entry.

✔ Cover exposed electrical connectors and terminals with dielectric grease to prevent corrosion.

✔ Use desiccant packets in storage containers to absorb moisture and prevent rust.

✔ Sealing engine openings protects internal components from environmental damage.

9. Rotate the Engine Periodically

For engines in long-term storage (1+ years), rotating the crankshaft periodically prevents internal sticking, corrosion, and loss of lubrication.

✔ Turn the crankshaft by hand every 30-60 days to move internal components and prevent seizure.

✔ Lubricate cylinders with fogging oil before rotating to protect rings and liners.

✔ If feasible, briefly run the engine every 6 months to circulate fluids and prevent degradation.

✔ Periodic rotation keeps engine components free-moving and lubricated.

Preparing the Engine for Long Periods of Inactivity

When preparing a Cummins B Series engine for seasonal or extended storage, follow these steps to ensure a smooth restart when the engine is put back into service.

1. Create a Storage Checklist

✔ Oil and filter changed before storage.

✔ Coolant checked and replaced if necessary.

✔ Fuel system drained or stabilized.

✔ Battery removed or maintained on a trickle charger.

✔ Engine components lubricated and protected from moisture.

✔ Storage environment optimized for minimal exposure to dust and humidity.

✔ A proper checklist ensures all critical steps are taken for safe engine storage.

2. Steps for Restarting the Engine After Storage

When bringing a stored engine back into operation, take these precautions:

✔ Check all fluid levels (oil, coolant, fuel) and replace as needed.

✔ Inspect belts, hoses, and seals for signs of cracking or deterioration.

✔ Reconnect the battery and check electrical connections.

✔ Remove intake and exhaust covers and check for obstructions.

✔ Prime the fuel system to ensure proper fuel delivery.

✔ Crank the engine briefly without starting to circulate oil before ignition.

✔ Start the engine and let it warm up gradually to operating temperature.

✔ Check for leaks, abnormal noises, or warning indicators.

✔ Following these steps ensures a smooth and safe startup after extended storage.

Final Thoughts

Proper storage and long-term maintenance are critical for preserving Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engines during periods of inactivity. By following best practices for storage, fuel system maintenance, corrosion prevention, and periodic inspections, you can:

✔ Prevent costly repairs and component failures.

✔ Ensure a smooth restart with minimal downtime.

✔ Maximize engine lifespan and reliability.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588