December 10, 2024

Alternator and Starter Motor Troubleshooting

1. Alternator Troubleshooting

2. Starter Motor Troubleshooting

Symptoms of Starter Issues

Inspection Procedures

1. Battery Check

2. Connections

3. Solenoid Functionality

4. Bench Testing

Resolution

Battery Maintenance and Charging Systems

Best Practices for Electrical System Maintenance

Conclusion

Read More

December 10, 2024

Inspection of Radiators, Heat Exchangers, and Water Pumps

1. Radiator Inspection

2. Heat Exchanger Inspection (Marine Applications)

1. Visual Inspection

2. Pressure Testing

3. Cleaning

4. Reassembly and Testing

5. Preventive Measures

3.Inspection and Maintenance of Heat Exchangers in Freshwater and Raw Water Pump Systems

1. Freshwater Pump Systems

2. Raw Water Pump Systems

Maintenance Procedures

Visual Inspection

Pressure Testing

Cleaning

Pump Maintenance

Preventive Measures

Reassembly and Final Testing

Advanced Coolant Testing (e.g., pH and Contaminants)

Procedures for Addressing Overheating and Blockages

1. Addressing Overheating

2. Clearing Blockages

Best Practices for Cooling System Maintenance

Conclusion

Read More

December 10, 2024

Advanced Injector Timing Techniques

Key Steps for Injector Timing

Governor Linkage Adjustments

Fuel Line Inspection and Replacement Guide

Inspection Procedures

Replacement Guide

Best Practices for Fuel Systems

Conclusion

Read More

December 9, 2024

Detailed Design and Functionality

Key Components

Functionality

Common Issues and Repairs

4. Actuator Malfunction

Oil Pressure Requirements and Testing Methods

1. Oil Pressure Requirements

2. Testing Methods

Best Practices for Hydraulic Systems

Conclusion

Read More

November 7, 2024

Key Functions For The Cylinder Head In A Detroit Diesel 149 Engine: Housing Exhaust Valves, Fuel Injectors, and Cooling Systems

Key Functions of the Cylinder Head

Common Issues: Addressing Wear, Valve Clearance, and Cylinder Head Replacement In The Detroit Diesel 149 Series Engine

Wear on Exhaust Valves and Seats

Maintaining Proper Valve Clearance

Injector Wear and Carbon Buildup

Cooling Passage Blockages

Cylinder Head Cracks and Warping

Head Gasket Failure For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Read More

November 7, 2024

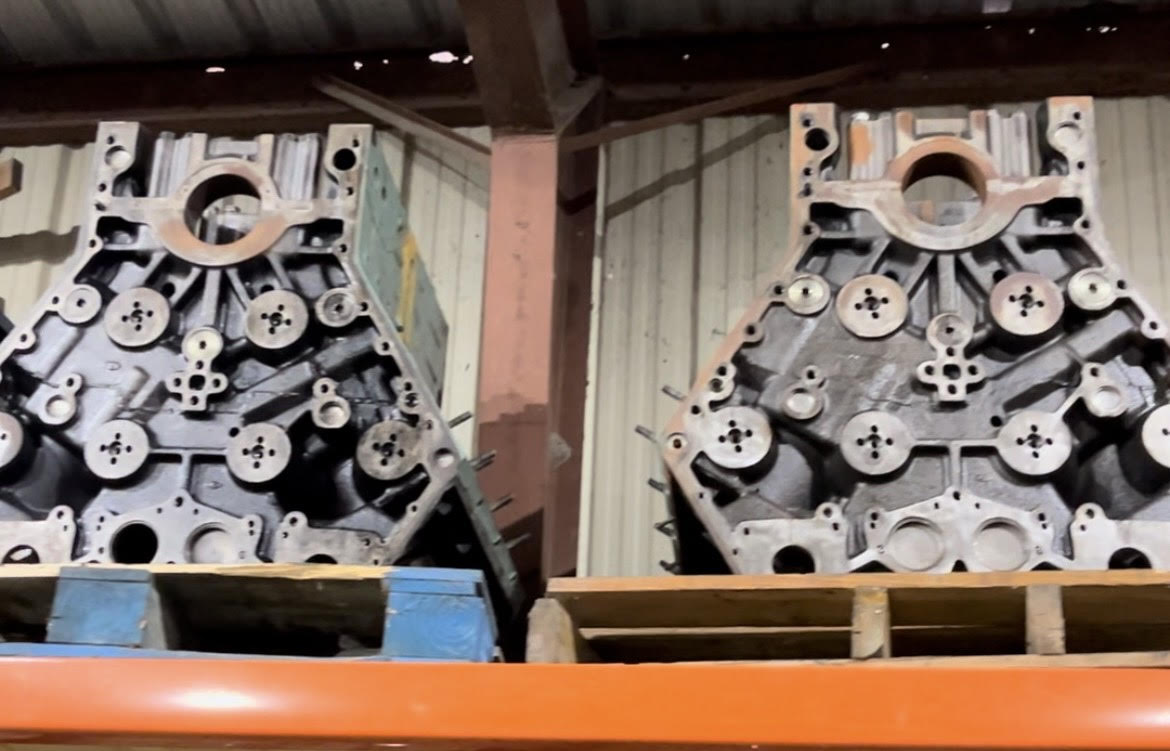

Structure and Role: The Detroit Diesel 149 Engine’s Main Frame

Heavy-Duty Cylinder Block Construction

Housing and Support for Critical Components

Integrated Cooling and Lubrication Systems

Structural Integrity and Load Distribution

Maintenance Tips: Ensuring Structural Integrity and Performance for Your Detroit Diesel 149 Cylinder Block

Inspecting for Cracks and Fractures

Checking Bearing Caps for Wear

Monitoring Bolt Torque and Thread Condition

Torque Specs By Component

Thread Size

Torque (lb-ft)

Torque (N·m)

Cleaning Cooling and Lubrication Passages

Ensuring Surface Flatness

Cleaning and Testing: Maintaining Optimal Condition of the Cylinder Block

Solvent Baths for Thorough Cleaning

Process:

Post-Bath Scrubbing:

Benefits:

Steam Cleaning to Clear Residual Buildup

Pressure Testing to Detect Leaks and Weaknesses

Magnetic Particle Inspection (MPI) for Crack Detection

Rust Prevention and Protective Coatings

Read More

Page 3 of 6«12345...»Last »

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588