June 2, 2025

Overview

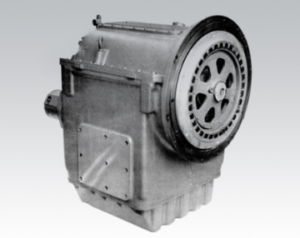

Twin Disc MG520 Ratios for Sale

Specifications, Dimensions, and Options

Key Features and Benefits

Engine Compatibility For The Twin Disc MG520

MTU Engines

John Deere, MAN, Scania, and Volvo Penta

Why Engine Compatibility Matters

Service Classifications

Important Notice

Videos About Twin Disc Transmissions

Read More

June 2, 2025

Overview

Twin Disc MG516 Ratios for Sale

Key Features and Benefits

Engine Compatibility for the Twin Disc MG516

Confirmed Compatible Engines

Additional Compatible Engines

Compatibility Considerations

SAE Housing and Installation Details

Duty Classification Performance Information

Installation and Maintenance

Service Classifications

Important Notice

Videos About Twin Disc Transmissions

Read More

June 2, 2025

Overview

Twin Disc MG527 Ratios for Sale

Key Features and Benefits

Engine Compatibility for the Twin Disc MG527

SAE Housing Details

Duty Classification Performance Information

Installation and Maintenance

Service Classifications

Important Notice

Videos About Twin Disc Transmissions

Read More

June 2, 2025

Rebuilt MG521 Transmissions Available for Immediate Purchase

Twin Disc MG521 Ratios for Sale

Key Features and Benefits

Engine Compatibility for the Twin Disc MG521

SAE Housing Details

Duty Classification Performance Information

Continuous Duty (Workboat Applications)

Intermediate Duty (and Pleasure Craft Service)

Pleasure Craft (Planing Hull)

Heat Exchanger Kits

Installation and Maintenance

Service Classifications

Important Notice

Videos About Twin Disc Transmissions

Read More

May 30, 2025

Rebuilt MG502 Transmissions Available for Immediate Purchase

Available Gear Ratios for Sale

Important Notice: Torsional Vibration

Why Choose a Twin Disc MG502 Rebuilt Transmission for Sale?

Expanded Specifications and Technical Details

Model:

Weight:

Oil Capacity:

Operating Pressure:

Recommended Oil:

Speed Range:

Design:

Key Components Included:

Performance Ratings

Engine Compatibility for the Twin Disc MG502 Rebuilt Marine Transmission

Detroit Diesel Compatibility

Cummins Compatibility

Caterpillar Compatibility

Construction Features

Real-World Applications

Conclusion – Ready to Meet Your Needs

Videos About Twin Disc Transmissions

Read More

Page 1 of 3712345...102030...»Last »

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588