Troubleshooting is a critical skill for anyone working with Cummins ISB and QSB engines. Whether you’re dealing with starting issues, unusual noises, or performance drops, a systematic approach to diagnosing problems can save time, reduce costs, and prevent unnecessary repairs. This comprehensive guide covers the step-by-step troubleshooting process, the importance of understanding engine symptoms, and common issues like starting failures, excessive smoke, overheating, and unusual noises.

Parts Catalog Main Page for Cummins ISB Marine Engine

Cummins ISB 4.5 & Related Components

Cummins ISB 5.9 & Related Components

Cummins ISB 6.7 & Related Components

Parts Catalog Main page for Cummins QSB Marine Engine

Cummins QSB 4.5 & Related Components

Cummins QSB 5.9 & Related Components

Cummins QSB 6.7 & Related Components

Cummins QSB 7.0 & Related Components

Step-by-Step Troubleshooting Process

A structured troubleshooting process helps identify engine issues efficiently and accurately. Here’s how to systematically approach problems with Cummins ISB and QSB engines.

1. Understand the Complaint

Before diving into diagnostics, gather detailed information about the problem:

- What are the symptoms? (e.g., rough idling, loss of power, smoke, unusual noises)

- When did the issue start? (e.g., after recent maintenance, sudden onset, gradual development)

- Is the problem consistent or intermittent?

- Has any recent work been done on the engine?

Talking to the operator or reviewing maintenance logs can provide valuable insights.

2. Perform a Visual Inspection

Many engine issues can be identified through a simple visual check:

- Check for Leaks: Look for oil, coolant, or fuel leaks around hoses, seals, and gaskets.

- Inspect Wiring and Connectors: Loose, damaged, or corroded electrical connections can cause intermittent problems.

- Look for Physical Damage: Cracked hoses, worn belts, or damaged components may be obvious sources of trouble.

- Check Fluid Levels: Low oil, coolant, or fuel levels can cause a range of performance issues.

3. Check for Diagnostic Trouble Codes (DTCs)

Modern Cummins ISB and QSB engines are equipped with an Electronic Control Module (ECM) that monitors engine performance and logs fault codes when issues are detected.

- Connect a Diagnostic Tool: Use Cummins’ INSITE software or a compatible diagnostic scanner to read DTCs.

- Interpret Codes: Refer to the Cummins fault code library to understand what each code means.

- Clear Codes: After addressing the issue, clear the codes and verify if they return during operation.

4. Test Engine Systems Systematically

Approach troubleshooting in a logical sequence:

- Fuel System: Check for fuel supply issues like clogged filters, air in the fuel lines, or weak fuel pumps.

- Air Intake System: Inspect air filters, turbochargers, and intercoolers for blockages or leaks.

- Cooling System: Ensure proper coolant flow, check for thermostat issues, and inspect for radiator blockages.

- Electrical System: Verify battery voltage, alternator output, and sensor functionality.

5. Perform Component Testing

If visual inspections and system checks don’t identify the problem, proceed with more specific tests:

- Compression Test: Identifies issues with piston rings, valves, or cylinder head gaskets.

- Fuel Pressure Test: Ensures the fuel system delivers proper pressure for combustion.

- Leak-Down Test: Detects internal leaks in the combustion chamber.

6. Verify Repairs

After addressing the identified issue:

- Run the Engine: Observe performance to ensure the problem is resolved.

- Check for New Codes: Re-scan the ECM for any recurring or new fault codes.

- Road Test (if applicable): For vehicles, conduct a test drive under normal operating conditions.

Importance of Understanding Engine Symptoms

Recognizing and interpreting engine symptoms correctly is key to effective troubleshooting. Symptoms often provide clues about the root cause of the problem.

1. Symptoms as Diagnostic Clues

Engine issues rarely occur in isolation. Understanding the context can help narrow down potential causes:

- When Does the Problem Occur? Is it during startup, under load, at idle, or at specific RPMs?

- Environmental Factors: Does temperature, humidity, or altitude affect the issue?

- Recent Changes: Has there been recent maintenance, part replacements, or software updates?

2. Common Symptom Categories

- Performance Issues: Loss of power, poor acceleration, stalling, or rough idling.

- Unusual Noises: Knocking, ticking, whining, or hissing sounds.

- Visual Indicators: Excessive smoke, fluid leaks, or dashboard warning lights.

- Operational Problems: Hard starting, overheating, or sudden shutdowns.

Correctly identifying these symptoms helps focus troubleshooting efforts and reduces the risk of misdiagnosis.

Common Symptoms and Their Causes

Now, let’s explore some of the most frequent issues encountered with Cummins ISB and QSB engines, their possible causes, and diagnostic approaches.

1. Engine Won’t Start

An engine that won’t start is one of the most common—and frustrating—problems. It can be caused by issues with the fuel system, electrical system, or mechanical components.

Possible Causes:

- Fuel System Issues:

- Empty fuel tank or contaminated fuel.

- Air in the fuel lines due to leaks or improper bleeding.

- Clogged fuel filters restricting fuel flow.

- Faulty fuel lift pump or injection pump.

- Electrical Problems:

- Weak or dead battery.

- Corroded or loose battery terminals.

- Faulty starter motor or solenoid.

- Malfunctioning ECM or blown fuses.

- Mechanical Issues:

- Low engine compression due to worn piston rings, valves, or head gasket failure.

- Timing issues with the camshaft or crankshaft.

Troubleshooting Steps:

- Check the Battery: Ensure proper voltage (typically 12.6 volts or higher when fully charged).

- Inspect Fuel Supply: Verify fuel level, check filters, and prime the fuel system if necessary.

- Listen for the Starter: A clicking noise may indicate a faulty solenoid, while no noise could suggest an electrical issue.

- Scan for DTCs: Look for codes related to fuel injection, sensors, or ECM faults.

Starter & Related Components for Cummins ISB 4.5 Engine

Starter & Related Components for Cummins ISB 5.9 Engine

Starter & Related Components for Cummins ISB 6.7 Engine

Starter & Related Components for Cummins QSB 4.5 Engine

Starter & Related Components for Cummins QSB 5.9 Engine

Starter & Related Components for Cummins QSB 6.7 Engine

Starter & Related Components for Cummins QSB 7.0 Engine

Fuel Pump & Related Components for Cummins ISB 4.5 Engine

Fuel Pump Injector & Related Components for Cummins ISB 5.9 Engine

Fuel Pump & Related Components for Cummins ISB 6.7 Engine

Fuel Pump & Injector & Related Components for Cummins QSB 4.5 Engine

Fuel Pump & Injector & Related Components for Cummins QSB 5.9 Engine

Fuel Pump & Injector & Related Components for Cummins QSB 6.7 Engine

Fuel Pump & Injector & Related Components for Cummins QSB 7.0 Engine

Injector & Related Components for Cummins ISB 4.5 Engine

Injector & Fuel Pump Related Components for Cummins ISB 5.9 Engine

Injector & Related Components for Cummins ISB 6.7 Engine

Injector & Fuel Pump Related Components for Cummins QSB 4.5 Engine

Injector & Fuel Pump Related Components for Cummins QSB 5.9 Engine

Injector & Fuel Pump Related Components for Cummins QSB 6.7 Engine

Injector & Fuel Pump Related Components for Cummins QSB 7.0 Engine

2. Excessive Smoke from the Exhaust

Diesel engines like the Cummins ISB and QSB naturally emit some smoke, but excessive smoke often signals underlying issues. The color of the smoke can help diagnose the problem:

White Smoke:

- Causes:

- Unburned fuel due to low compression, injector problems, or incorrect timing.

- Coolant leaking into the combustion chamber (blown head gasket or cracked cylinder head).

- Cold weather start without proper glow plug function.

- Troubleshooting:

- Check coolant levels for signs of internal leaks.

- Perform a compression test.

- Inspect fuel injectors for leakage.

Black Smoke:

- Causes:

- Excess fuel or poor combustion due to clogged air filters, faulty turbochargers, or bad injectors.

- EGR system malfunction causing improper air-to-fuel ratios.

- Troubleshooting:

- Check the air intake system for restrictions.

- Inspect the turbocharger for damage or oil leaks.

- Verify proper fuel injection timing.

Blue Smoke:

- Causes:

- Burning engine oil due to worn piston rings, valve seals, or turbocharger seals.

- Overfilled oil reservoir causing oil to enter the combustion chamber.

- Troubleshooting:

- Check oil levels and inspect for leaks.

- Perform a cylinder leak-down test to assess internal engine wear.

Injector & Related Components for Cummins ISB 4.5 Engine

Injector & Fuel Pump Related Components for Cummins ISB 5.9 Engine

Injector & Related Components for Cummins ISB 6.7 Engine

Injector & Fuel Pump Related Components for Cummins QSB 4.5 Engine

Injector & Fuel Pump Related Components for Cummins QSB 5.9 Engine

Injector & Fuel Pump Related Components for Cummins QSB 6.7 Engine

Injector & Fuel Pump Related Components for Cummins QSB 7.0 Engine

3. Engine Overheating Issues

Overheating can cause severe engine damage, including warped cylinder heads and blown gaskets. Common causes include cooling system failures or operational issues.

Possible Causes:

- Cooling System Problems:

- Low coolant levels due to leaks.

- Faulty water pump not circulating coolant properly.

- Clogged radiator or restricted coolant flow.

- Stuck thermostat preventing coolant from flowing.

- External Factors:

- Heavy load conditions or extreme ambient temperatures.

- Blocked airflow to the radiator.

- Mechanical Issues:

- Blown head gasket causing coolant loss into combustion chambers.

- Failed cooling fan or viscous fan clutch.

Troubleshooting Steps:

- Check Coolant Levels: Inspect for visible leaks in hoses, radiators, and the water pump.

- Inspect the Radiator: Look for blockages, corrosion, or physical damage.

- Test the Thermostat: Remove and test in hot water to ensure it opens at the correct temperature.

- Pressure Test the Cooling System: Identify hidden leaks or pressure losses.

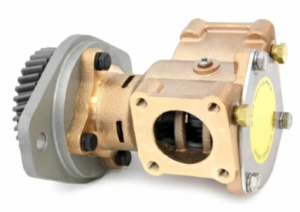

Freshwater Pump & Related Components for Cummins ISB 4.5 Engine

Freshwater Pump & Related Components for Cummins ISB 5.9 Engine

Freshwater Pump & Related Components for Cummins ISB 6.7 Engine

Freshwater Pump & Related Components for Cummins QSB 4.5 Engine

Freshwater Pump & Related Components for Cummins QSB 5.9 Engine

Freshwater Pump & Related Components for Cummins QSB 6.7 Engine

Freshwater Pump & Related Components for Cummins QSB 7.0 Engine

Raw Water Pump & Related Components for Cummins QSB 5.9 Engine

Raw Water Pump & Related Components for Cummins QSB 6.7 Engine

Raw Water Pump & Related Components for Cummins QSB 7.0 Engine

4. Unusual Engine Noises

Unusual noises are often the first sign of internal engine issues. Identifying the type, location, and frequency of the noise can help pinpoint the problem.

Common Types of Noises:

- Knocking or Pinging:

- Low-quality fuel causing detonation.

- Advanced ignition timing.

- Worn rod bearings or main bearings.

- Ticking or Clicking:

- Valve lash out of adjustment.

- Faulty hydraulic lifters or rocker arms.

- Injector issues causing uneven combustion.

- Whining or Whistling:

- Turbocharger bearing failure.

- Air leaks in the intake system.

- Failing alternator or serpentine belt tensioner.

- Grinding or Rattling:

- Damaged timing gears or chains.

- Loose engine mounts or accessories.

Troubleshooting Steps:

- Isolate the Noise: Use a mechanic’s stethoscope to locate the source of the sound.

- Check for Loose Components: Inspect belts, pulleys, and external accessories.

- Listen for Changes: Note if the noise changes with engine RPM or load.

- Perform Oil Analysis: Check for metal particles that could indicate internal wear.

Preventive Measures for Reducing Troubleshooting Frequency

While troubleshooting is essential when problems occur, preventive maintenance is the best way to reduce the frequency and severity of engine issues:

- Regular Oil Changes: Prevents sludge buildup and reduces internal wear.

- Timely Fuel Filter Replacements: Ensures clean fuel delivery and protects injectors.

- Cooling System Maintenance: Regularly flush coolant and inspect for leaks.

- Air Filter Inspection: Clean filters improve engine efficiency and prevent contaminants from entering.

Conclusion

Troubleshooting Cummins ISB and QSB engines requires a systematic approach to identify and address problems efficiently. By understanding common symptoms, following diagnostic procedures, and maintaining preventive practices, you can ensure reliable engine performance and minimize downtime. Always prioritize safety when performing engine diagnostics and consider consulting professional support for complex issues.

Parts Catalog Main Page for Cummins ISB Marine Engine

Cummins ISB 4.5 & Related Components

Cummins ISB 5.9 & Related components

Cummins ISB 6.7 & Related Components

Parts Catalog Main page for Cummins QSB Marine Engine

Cummins QSB 4.5 & Related Components

Cummins QSB 5.9 & Related Components

Cummins QSB 6.7 & Related Components

Cummins QSB 7.0 & Related Components

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588