Introduction

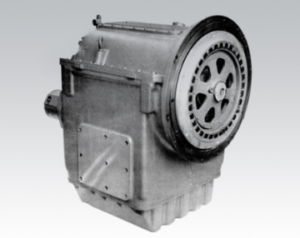

The Twin Disc MG527 Marine Gear is one of the most respected transmissions in the marine industry, known for its strength, longevity, and versatility in both commercial and recreational vessels. But with so many moving parts, oil specifications, performance tolerances, and rebuild options, operators often have questions about how to maintain, troubleshoot, and optimize their MG527 transmission.

This FAQ covers the 50 most common questions from vessel owners, fleet mechanics, and marine service professionals to help you make smarter, faster decisions when it comes to service, parts replacement, and long-term care for your MG527 gear.

Parts Catalog for Twin Disc MG527 Marine Transmissions

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

General Information

The video below features a Detroit Diesel 12V149 that is connected to a Twin Disc MG527.

- What is the Twin Disc MG527 Marine Gear?

The MG527 is a heavy-duty marine transmission that connects the propulsion engine to the propeller shaft. It provides forward, neutral, and reverse propulsion using a hydraulic clutch system.

- What kind of vessels use the MG527?

The MG527 is commonly found in tugboats, trawlers, pilot boats, ferries, workboats, and sportfishing yachts.

- What is the rated input horsepower for the MG527?

The MG527 typically handles between 400 to 660 horsepower depending on configuration, operating speed, and gear ratio.

- What gear ratios are available for the MG527?

Popular ratios include 1.5:1, 2.0:1, 2.5:1, 2.95:1, 3.0:1, 3.5:1, and 4.0:1.

- How does the hydraulic clutch system work in the MG527?

Hydraulic pressure activates clutch packs that engage or disengage the transmission. The system is powered by an internal pump driven by the input shaft.

Installation and Setup

- Can the MG527 be installed in twin engine configurations?

Yes. It is suitable for both single and twin engine setups when properly aligned and matched with engine power and propeller load.

- What should I consider when aligning the MG527 during installation?

The engine, transmission, and propeller shaft must be precisely aligned using dial indicators or laser alignment tools. Improper alignment causes vibration and bearing wear.

- Does the MG527 require an oil cooler?

Yes. A dedicated transmission oil cooler is essential to maintain proper operating temperatures and prevent overheating.

- Can I install the MG527 myself?

Marine transmission installation should only be performed by qualified personnel. Specialized tools and torque specifications are required to avoid damage.

- Is the MG527 compatible with electronic control systems?

Yes. It is commonly paired with systems like the EC300 or other shift control modules.

Oil and Fluids

- What type of oil is used in the MG527?

Use SAE 30 or SAE 40 marine-grade engine oil that meets CF, CF-2, or CG-4 API classifications. Synthetic oils may be used if they meet the same specifications.

- How much oil does the MG527 hold?

Most setups require between 2.5 to 5 gallons, depending on whether the oil cooler and lines are included in the total volume.

- How often should I change the transmission oil?

Every 250 operational hours or every 6 months, whichever comes first.

- What happens if I overfill the MG527 with oil?

Overfilling can lead to oil foaming, loss of hydraulic pressure, overheating, and clutch slippage.

- Can I use ATF in the MG527?

Some light-duty MG527 applications allow ATF use, but it’s not recommended for high-load, commercial, or tropical operations unless specified.

Routine Maintenance

- What should I inspect daily before operating the vessel?

Check oil level, look for leaks, confirm smooth shift engagement, and listen for abnormal noise.

- What maintenance is required every 250 hours?

Change the oil, inspect the filter, clean the magnetic drain plug, and check hydraulic pressure at idle and cruising speed.

- How often should I inspect the clutch pack?

Inspect the clutch pack at 1,000-hour intervals or sooner if slippage is suspected.

- When should the output shaft seal be replaced?

Replace the seal if there’s visible oil leakage or during every major rebuild or bearing service.

- Can I flush the MG527 with solvents?

No. Only use approved flushing fluids compatible with marine transmission seals and materials.

Troubleshooting

- What causes slipping in the MG527?

Low hydraulic pressure, worn clutch discs, or contaminated oil are the most common causes.

- Why is there a delay in engagement when shifting?

This may be due to air in the hydraulic system, worn clutch plates, or improper shift cable calibration.

- My transmission is overheating—what should I check?

Check oil level, inspect the oil cooler for blockages, verify raw water flow, and ensure oil is within spec.

- I hear whining from the rear of the gearbox—what does this mean?

Whining typically points to output bearing wear or low oil pressure. Check both immediately.

- What causes vibration in the transmission?

Common causes include shaft misalignment, worn output bearings, unbalanced propeller, or damaged couplings.

Performance and Operation

- How quickly should the MG527 engage forward or reverse?

Proper engagement should occur within 0.5 to 1 second at idle. Delays indicate a pressure or clutch issue.

- Can I shift the gear at high RPM?

No. Always shift at idle speed to prevent damage to internal clutches and gears.

- Is there a neutral safety mechanism on the MG527?

Yes. Most systems include a mechanical or electronic neutral detent to prevent gear engagement during startup.

- What oil temperature is too high for the MG527?

Operating oil temperature should stay below 200°F. Temperatures above 220°F can damage seals and reduce oil life.

- Can I install a temperature gauge on the MG527?

Yes. Many operators add analog or digital sensors to monitor transmission oil temperature in real time.

Rebuild and Repair

- How do I know if the MG527 needs a rebuild?

Signs include excessive noise, slipping, delayed engagement, metal in the oil, and loss of hydraulic pressure.

- What comes in a complete rebuild kit?

A rebuild kit typically includes clutch discs, steel plates, seals, gaskets, bearings, snap rings, and shims.

- Can I rebuild the MG527 myself?

Experienced technicians with the proper tools can rebuild the MG527, but it requires precision and technical knowledge.

- How long does a rebuild take?

A typical rebuild, including removal and reinstallation, takes 2–5 days depending on parts availability and experience.

- Where can I find a reliable rebuild kit?

Aftermarket suppliers offer rebuild kits that match OEM specs and ship faster, often at better prices.

Parts Support

- Are aftermarket parts reliable for the MG527?

Yes. Premium aftermarket parts are built to OEM tolerances and provide excellent performance and durability.

- What parts should I replace during a minor service?

Replace oil, filter, shaft seals, and gaskets. Inspect clutch plates, bearings, and mounts.

- Can I get the MG527 as a complete remanufactured unit?

Yes. Some suppliers offer remanufactured MG527s that have been rebuilt and tested to factory specs.

- Are Twin Disc MG527 parts still in production?

Yes, but OEM lead times can be long. Aftermarket suppliers can fill the gap with in-stock parts.

- Is it better to replace individual parts or buy a complete kit?

A complete rebuild kit ensures all components are compatible and saves time sourcing individual parts.

Storage and Off-Season Use

- How should I store my MG527 during the off-season?

Change the oil, lubricate shift linkages, cap vents, and run the gear briefly at idle before laying up.

- Should I fog the gear for storage?

Fogging is not required, but lightly circulating clean oil and sealing off air inlets can prevent corrosion.

- Can cold weather damage the MG527?

Yes. Freezing oil or moisture inside can crack seals or damage internals. Store in a temperature-controlled environment.

- How often should I inspect the gear during lay-up?

Check monthly for leaks, condensation, or signs of seal shrinkage.

- What should I do before restarting after storage?

Inspect oil level, look for leaks, shift gears manually, and run at idle for 15–20 minutes before operating under load.

Best Practices

- How can I extend the life of my MG527?

Use high-quality fluids, follow oil change intervals, avoid hard shifts, monitor alignment, and store properly.

- Should I use synthetic oil in the MG527?

Yes, if it’s compatible with your seals and operating conditions. Synthetic oil can provide better protection and longer service intervals.

- What alignment tools are best for shaft setup?

Dial indicators, feeler gauges, or laser alignment tools are ideal for marine transmission alignment.

- Can I pressure wash the outside of the gear?

Yes, but avoid directly spraying seals, vent caps, and electrical connections.

- Where can I find technical help or parts for the MG527?

Marine transmission specialists and aftermarket parts providers can offer expert help, fast shipping, and rebuild support.

Conclusion

The Twin Disc MG527 Marine Gear is one of the most durable and respected gearboxes in the marine industry, but like any precision mechanical system, it performs best when properly maintained, monitored, and rebuilt with high-quality parts.

By understanding these 50 FAQs, you can make smarter decisions, avoid costly failures, and keep your vessel in service longer.

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588