Twin Disc MG 527 Marine Transmission Parts - Overhaul Plate Kit Section

Loading...

Loading... Twin Disc MG 527 Marine Transmission Parts — Overhaul Plate Kit Section

Overview: MG527 Overhaul Plate Kits Built for Real-World Duty Cycles

When a Twin Disc MG527 starts to slip under throttle, heats up in demanding maneuvers, or leaves metallic fines in the oil, the clutch packs are almost always the first place to look. Our Overhaul Plate Kit for Twin Disc MG527 is a purpose-built clutch plate and reaction plate set designed to restore positive engagement, consistent torque transfer, and predictable shifting across the common MG527 ratios (2:1, 3:1, 4:1, and 5:1). This section explains exactly what’s in the kit, how to select the right configuration for your gearbox, what to pair it with (gasket & seal set, rubber blocks, and other supporting components), and how to avoid the most common mistakes that shorten clutch life.

Diesel Pro Power has supported marine operators for decades—from commercial fishing vessels and crew boats to work barges, yachts, and patrol craft. We back our MG527 parts program with fast shipping, responsive bilingual support (English/Español), and a catalog curated specifically around the MG527 platform. Our customer base includes 40,000+ satisfied customers worldwide who rely on us to keep their vessels moving.

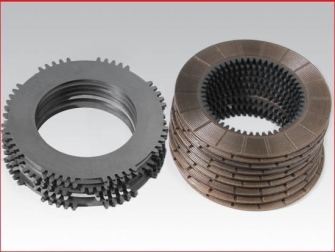

What’s Included: MG527 Overhaul Plate Kit (Clutch Pack)

Core Components You Can Expect

-

Friction Plates (Clutch Plates)

Precisely machined discs with friction lining engineered for repeatable engagement and controlled slip during shifting. The friction profile is selected to balance holding capacity with smoothness. -

Steel Reaction Plates (Counter Plates)

Flat, hardened steels that provide a stable mating surface for the friction plates. Proper hardness and flatness are critical to heat dissipation and plate longevity. -

Stack Arrangement Guidance

The friction and steel plates are supplied in counts appropriate for the MG527’s clutch packs, allowing you to build the correct alternating sequence (friction–steel–friction–steel, etc.) for the target ratio build. -

Application Notes

Notes to help you match the clutch pack to MG527 variants (ratios such as 2:1, 3:1, 4:1, 5:1), with reminders about verifying internal variations before assembly.

Why the MG527 Benefits from a Full Plate Refresh

-

Heat Management: Fresh friction and properly flat steels recover the gearbox’s ability to shed heat during heavy maneuvers.

-

Holding Capacity: Worn or glazed plates lose static friction, leading to slippage. New plates restore holding torque.

-

Shift Quality: Correct plate surface finish and stack height bring back crisp, predictable gear engagement.

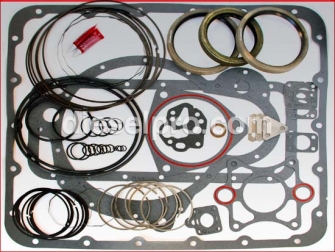

Companion Kit: MG527 Gasket & Seal Kit

Clutch overhauls should be paired with a new Gasket and Seal Kit for MG527. Opening the case and handling the clutch drums introduces opportunities for contamination and seal damage; reusing old elastomers often leads to weeping or pressure losses that undermine the clutch work you just performed.

What the Gasket & Seal Kit Typically Covers

-

Case Gaskets & Inspection Cover Gaskets

To properly reseal opened housings and access points. -

Input/Output Shaft Seals

To maintain oil containment and correct internal pressure. -

Pump O-Rings and Seals

To protect the lifeblood of the transmission—hydraulic pressure—from bypass or loss. -

Selector Shaft/Control End Seals (Where Applicable)

To prevent external leaks near controls that can be misdiagnosed as “case seepage.”

Pairing the Two Kits

-

Best Practice: Replace friction plates, steels, and all disturbed gaskets and seals in one service window.

-

Result: A dry, tight gearbox that holds pressure, protects new clutch materials from oil aeration, and stabilizes operating temperature.

Vibration Control: Rubber Block for Twin Disc Marine Gears

The Rubber Block (Tacón de goma / Bushing) is a simple, inexpensive component that absorbs torsional spikes transmitted through couplings and driveline interfaces. While it appears in compatibility lists with several Twin Disc models (MG5111, MG5111A, MG5114, MG5114A, MG514A/B, MG514C, MG516, MG518, MG521, MG527), it has very practical value on MG527 installations.

Why Replace the Rubber Block During an MG527 Overhaul

-

Torsional Damping: Fresh elastomer keeps torsional vibrations in check, protecting the newly installed clutch packs from chatter and micro-slip.

-

Noise & Comfort: Reduces drivetrain harshness, improving helm feel and passenger comfort.

-

Add-On Value: Low cost, high impact—especially on vessels with duty cycles that include frequent docking maneuvers, towing/pushing, or stop-and-go operations.

Selecting the Correct MG527 Overhaul Plate Kit

Confirm Your Transmission Credentials

-

Model Tag: Locate the Twin Disc nameplate on the gearbox (typically on the housing). Confirm MG527.

-

Gear Ratio: Identify the ratio (e.g., 2:1, 3:1, 4:1, 5:1). The ratio influences clutch pack configuration and expectations for heat load and holding torque.

-

Operating Profile: Continuous duty vs. intermittent, high-load towing vs. cruise. This helps anticipate maintenance cadence and oil selection.

Order Preparation Checklist

-

MG Model: MG527

-

Ratio: 2:1 / 3:1 / 4:1 / 5:1 (confirm tag)

-

Vessel/Application Notes: Workboat, sportfish, crew boat, patrol craft, etc.

-

Companion Needs: Gasket & Seal Kit, Rubber Block, fresh oil and filters

-

Observed Symptoms: Slipping under throttle? Overheat alarms? Metal fines on magnetic drain plug?

Diagnosing MG527 Clutch Wear Before You Open the Case

Tell-Tale Signs

-

RPM Flare at Shift or Under Load: Engine revs increase without proportional boat speed—classic clutch slip.

-

Discolored/Smoky Oil: Overheated clutch packs can darken oil; burnt odor is a red flag.

-

Mag Plug Debris: Excessive metallic fines or plate material indicates wear.

-

Temperature Creep: Gearbox temperatures trending higher during normal operations may indicate friction material nearing end of life.

Pre-Work Sanity Checks

-

Oil Level & Condition: Underfill or wrong oil viscosity can mimic slippage. Correct these first; if symptoms persist, plan the overhaul.

-

Filter Health: A partially plugged filter reduces hydraulic pressure—clutch packs won’t clamp properly.

-

Control Calibration: Ensure control cable/actuator travel is correct and free from binding.

Inside the Kit: Quality Dimensions that Matter

Friction Plate Considerations

-

Flatness and Parallelism: Minimizes hot spots and uneven wear.

-

Friction Surface Quality: The right texture supports oil film control and consistent coefficient of friction.

-

Edge Integrity: Clean chamfers reduce stress risers and ease assembly.

Steel Plate Considerations

-

Hardness & Tempering: Critical to resisting scoring and preserving surface finish under heat.

-

Thermal Stability: Steels designed to stay true help preserve stack height and engagement consistency.

-

Surface Finish: Optimized for the friction material’s designed mating characteristics.

Lubrication & Cooling: Protecting Your New MG527 Clutch Packs

Oil Choice & Change Intervals

-

Use the Specified Oil Type: Follow Twin Disc’s recommended oil spec and viscosity band for ambient conditions.

-

Change Cadence: If your duty cycle involves heavy towing, frequent docking, or hot climates, shorten oil and filter intervals. Clean oil is the cheapest insurance for clutch longevity.

Heat Is the Enemy

-

Monitor Temperature Trends: If oil temps are climbing faster than before, investigate—cooler fouling, heat exchanger issues, or low flow can cook new plates.

-

Keep the Oil Clean: Abrasive fines accelerate wear. New clutches shed a normal break-in amount; filters should be checked early in the first service hours after overhaul.

Stack Height & Engagement Behavior (Concepts to Discuss with Your Technician)

Why Stack Height Matters

-

Clamp Load Consistency: Correct stack height allows pistons to develop full clamp force within the hydraulic system’s design range.

-

Shift Quality: Too short a stack can cause harsh shifts; too tall can cause partial engagement or drag.

-

Predictable Life: When tolerances are respected, the clutch ages uniformly and predictably.

Note: Your professional marine transmission technician will measure and confirm stack height during assembly. The overhaul plate kit provides the correct components; precise validation occurs during build.

Pairing Components for a “One-and-Done” MG527 Service Window

Recommended Bundle for a Comprehensive Service

-

Overhaul Plate Kit (Friction + Steels)

-

Gasket & Seal Kit

-

Rubber Block

-

New Oil & Filters

-

Inspection Consumables (lint-free wipes, magnets for inspection, etc.)

Why Bundle?

-

Labor Efficiency: Pulling the gearbox once and resealing everything saves haul-out time and technician hours.

-

Reliability: New seals protect new plates from contaminated oil or pressure loss.

-

Comfort: A fresh rubber block improves feels-like-new operation at the helm.

Common MG527 Questions (FAQs)

How do I know my MG527 actually needs an overhaul plate kit?

If you’re experiencing slip under load, rising operating temperatures, burnt-smelling oil, or fines on the magnetic drain plug, your clutch packs are suspect. Confirm proper oil type, level, and filter condition first. Persistent symptoms point strongly to clutch wear.

Do I need the gasket & seal kit if I’m only replacing plates?

Yes. Any time you open the gearbox, plan to replace disturbed gaskets and seals. Proper sealing preserves hydraulic pressure and keeps new clutch surfaces clean.

Will the rubber block really make a difference?

On vessels with frequent maneuvering, towing, or variable load, yes. It smooths torsional spikes that can promote clutch chatter or micro-slip, protecting your investment.

Which ratios does this apply to?

The overhaul plate kit offering here is focused on the Twin Disc MG527 platform and is used across common ratio configurations 2:1, 3:1, 4:1, and 5:1. Always verify your nameplate ratio to align expectations and maintenance intervals.

Can I reuse steel plates if they “look okay”?

Reusing steels may compromise the refresh. Even lightly blued or slightly warped steels undermine friction performance and heat management. A complete set ensures matched, flat, and properly hardened steels.

Do I need to adjust maintenance after installing new plates?

It’s smart to perform an earlier oil and filter change in the first service hours after overhaul, then follow your standard interval (shortened if you operate in heavy-duty cycles). Monitor temperature and engagement feel; stable trends indicate a healthy build.

Practical Field Tips for Longer MG527 Clutch Life

Avoid Prolonged Partial Engagement

Riding the clutch during slow docking maneuvers builds heat fast. Use short, decisive shifts and let the clutch fully engage.

Warm Up Before Heavy Loads

Allow oil to reach operating temperature before high-torque maneuvers. Cold oil can delay full pressure, momentarily reducing clamp load.

Keep Coolers Clean

A fouled heat exchanger turns good clutches into glazed clutches. Clean and pressure-test the cooling side at regular intervals.

Standardize Oil Across Fleet

Consistent oil type and viscosity across similar gearboxes simplifies inventory and avoids mix-ups.

Why Buy Your MG527 Kits from Diesel Pro Power

Focused MG527 Catalog

We build our marine transmission catalog around real-world demand for the MG527, stocking the clutch kits, gasket & seal sets, and supporting parts that technicians actually need on the bench.

Fast, Reliable Fulfillment

Marine downtime is costly. We prioritize rapid order processing and practical packaging so kits arrive ready for the job.

Bilingual, Knowledgeable Support

English/Español support from a team that understands Twin Disc service conventions and the MG527 platform.

Proven by 40,000+ Customers

Commercial operators and private owners worldwide trust us for critical-path marine drivetrain components.

No-Nonsense Quality

We focus on fit, function, and durability. The goal is simple: get your MG527 back to crisp engagement, stable temperatures, and reliable service—without repeat work.

Quick Reference: Matching Parts to the MG527

Overhaul Plate Kit for MG527

-

Purpose: Restore clutch holding capacity and shift quality

-

Includes: Friction plates + steel reaction plates in the counts needed for MG527 clutch pack builds

-

Use Cases: Slippage, heat issues, contaminated oil, scheduled heavy-duty refresh

Gasket & Seal Kit for MG527

-

Purpose: Ensure leak-free reassembly and stable hydraulic pressure

-

Includes: Case gaskets, shaft seals, O-rings, and related sealing elements appropriate to the MG527

-

Use Cases: Any time the case is opened; preventive maintenance

Rubber Block (Compatible Across Twin Disc Models Including MG527)

-

Purpose: Torsional damping; reduce driveline harshness and chatter

-

Use Cases: Overhaul time, vibration complaints, clutch chatter, general comfort upgrades

Symptom-to-Solution Guide

Symptom: Slips Under Acceleration

-

Likely Cause: Worn/friction-glazed plates or low hydraulic pressure

-

Solution: Overhaul plate kit + gasket & seal kit; verify oil spec and filter health

Symptom: Temperature Alarms or Rising Oil Temps

-

Likely Cause: Clutch friction generating excess heat; compromised cooling

-

Solution: Overhaul plate kit; service cooler; confirm oil flow and cleanliness

Symptom: Metallic Fines on Mag Plug

-

Likely Cause: Normal wear reaching end of life or accelerated wear from contaminated oil

-

Solution: Overhaul plate kit; flush and refill with correct oil; early post-overhaul filter change

Symptom: Chatter During Engagement

-

Likely Cause: Torsional vibration, rough steels, or glazing

-

Solution: Overhaul plate kit with fresh steels; add/replace rubber block; verify idle speed and control travel

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588