Sea Water Pumps For Cummins Engines

Sea Water Pumps for Cummins Marine Engines

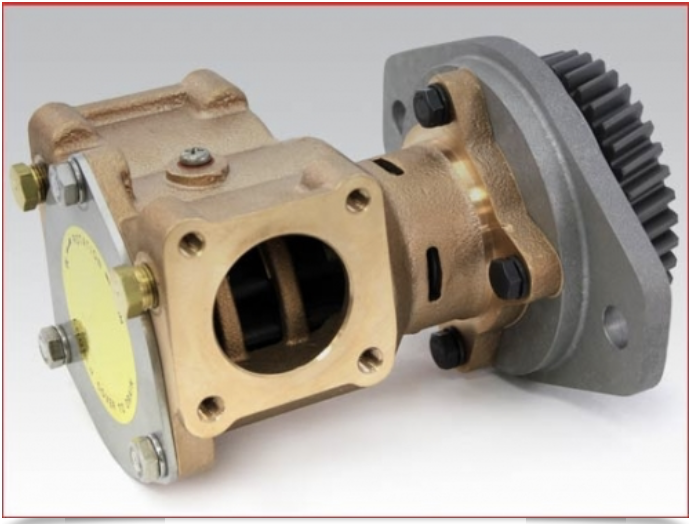

Sea water pumps for Cummins marine engines play a vital role in maintaining proper operating temperature by drawing raw water directly from the surrounding body of water and circulating it through the engine’s cooling system. This raw water is used to cool heat exchangers, aftercoolers, oil coolers, and exhaust components before being discharged overboard. Without a reliable sea water pump, engine temperatures can rise rapidly, increasing the risk of overheating, power loss, or severe internal damage.

Why Sea Water Pumps Are Critical for Engine Cooling

Cummins marine engines are designed to operate under continuous load, often for long hours at sea. While these engines rely on a closed-loop coolant system internally, the raw water pump is what removes heat from that system. If raw water flow is restricted or stops entirely, coolant temperatures climb quickly, which can lead to warped cylinder heads, damaged exhaust components, or even engine seizure. A properly functioning sea water pump ensures consistent cooling performance, even in demanding marine conditions.

Designed for Marine-Specific Operating Conditions

Sea water pumps are especially important in marine applications because saltwater environments introduce corrosion, marine growth, and debris that can accelerate wear. Cummins marine-rated pumps are built with corrosion-resistant housings, robust shafts, and replaceable impellers designed to withstand continuous exposure to seawater. Compared to relying on airflow alone—which is insufficient in enclosed engine rooms—raw water cooling provides far more effective temperature control.

Installation, Serviceability, and Maintenance

Sea water pumps are typically belt-driven or gear-driven and mounted externally on the engine, making them relatively easy to access for inspection and service. They connect to the cooling system via marine-grade hoses and seacocks, allowing for straightforward removal and replacement when servicing is required. Routine maintenance usually involves periodic impeller inspection or replacement to ensure proper water flow. Many pumps can also be adjusted or serviced in place, helping operators maintain the correct cooling capacity and minimize downtime.

Step By Step Guides To Install Your New Cummins Sea Water Pumps

Installing a Cummins sea water pump correctly is critical to maintaining proper engine cooling and preventing overheating in marine applications. These pumps play a vital role by supplying raw water to the heat exchanger, aftercooler, and exhaust system, ensuring engine temperatures remain within safe operating limits. Improper installation can lead to leaks, reduced water flow, premature pump failure, or serious engine damage—especially in continuous-duty marine environments.

This step-by-step guide is designed to walk marine mechanics, vessel owners, and fleet operators through the correct installation process for Cummins marine sea water pumps. From preparation and inspection to alignment, sealing, and final checks, each step focuses on best practices that help ensure reliable operation and long service life. Whether you’re replacing a worn pump during routine maintenance or installing a new unit as part of a larger repair, following these procedures will help you restore proper cooling performance and keep your Cummins marine engine running safely and efficiently on the water.

- A Step-by-Step Guide to Installing a Cummins 6BTA Sea Water Pump

- A Step-by-Step Guide to Installing a Cummins QSM Sea Water Pump

Cummins Marine Engine Raw Water Pump Catalog

Raw water pumps are a critical component of Cummins marine engine cooling systems, responsible for supplying seawater to heat exchangers, aftercoolers, oil coolers, and exhaust systems. In marine environments, these pumps operate continuously under load while exposed to saltwater, heat, and vibration—making proper selection and maintenance essential to engine reliability. A worn or failing raw water pump can quickly lead to overheating, loss of cooling flow, and costly engine damage if not addressed promptly.

This Cummins Marine Engine Raw Water Pump Catalog is designed to help marine mechanics, vessel owners, and fleet operators quickly identify the correct pump for their specific Cummins marine engine. The catalog covers a wide range of Cummins platforms, from smaller B Series engines to larger commercial and heavy-duty models used in workboats, fishing vessels, and offshore applications. Each pump listed is marine-rated and engineered to meet or exceed OEM specifications for fitment, flow rate, and durability.

By using this catalog, you can confidently source the correct raw water pump for routine maintenance, emergency replacement, or complete engine overhauls—helping ensure proper cooling performance, reduced downtime, and long-term reliability for your Cummins marine engine.

Sea water Pump Pump for 4B Cummins Marine Engine

Sea water Pump for 4BT Cummins Marine Engine

Sea water Pump for 4BTA Cummins Marine Engine

Sea water Pump for 6B Cummins Marine Engine

Sea water Pump for 6BT Cummins Marine Engine

Sea water Pump for 6BTA Cummins Marine Engine

Sea water Pump for QSB 5.9 Cummins Marine Engine

Sea water Pump for QSB 6.7 Cummins Marine Engine

Sea water Pump for QSB 7.0 Cummins Marine Engine

Sea water Pump for 6C Cummins Marine Engine

Sea water Pump for 6CT Cummins Marine Engine

Sea water Pump for 6CTA Cummins Marine Engine

Sea water Pump for QSC Cummins Marine Engine

Sea water Pump for QSL Cummins Marine Engine

Sea water Pump for QSM Cummins Marine Engine

Sea water Pump for NH855 Cummins Marine Engine

Sea water Pump for NT855 Cummins Marine Engine

Sea water Pump for KTA19 Cummins Marine Engine

Sea water Pump for KTA38 Cummins Marine Engine

Sea water Pump for KTA50 Cummins Marine Engine

Sea water Pump for QSK19 Cummins Marine Engine

Why Customers Choose Diesel Pro Power Raw Water Pumps

Raw water pumps are a mission-critical component in any Cummins, Detroit Diesel, or Caterpillar marine engine. When cooling flow stops, engines overheat fast—often with expensive consequences. That’s why different decision-makers across the marine industry consistently choose Diesel Pro Power raw water pumps. Each group values reliability, but for different reasons.

1) Why Fleet Owners Buy Our Raw Water Pumps

-

Protect Revenue-Producing Assets

Reliable raw water pumps prevent overheating failures that can sideline vessels and destroy engines. -

Lower Total Cost of Ownership

Marine-grade pumps and replaceable impellers reduce repeat failures and extend service intervals. -

Predictable Reliability Offshore

Pumps are built to handle continuous-duty operation in saltwater environments. -

Support for Legacy Engines

Availability for older Cummins, Detroit Diesel, and Caterpillar models still earning income. -

One Supplier Accountability

Fleet owners value a single trusted source rather than juggling multiple vendors.

2) Why Fleet Managers Choose Our Raw Water Pumps

-

Reduced Downtime Across the Fleet

In-stock inventory and fast shipping support scheduled maintenance and emergency repairs. -

Consistent Fitment Across Vessels

Engine-specific pumps reduce ordering errors and installation delays. -

Standardization of Parts

Using the same pump designs simplifies maintenance planning and onboard spares. -

Durability Under Continuous Load

Pumps are selected for commercial duty cycles, not light recreational use. -

Reliable Supplier Support

Knowledgeable staff assist with cross-referencing, upgrades, and replacements.

3) Why Marine Mechanics Trust Our Raw Water Pumps

-

Correct Fitment, First Time

Accurate part matching by engine model and serial number prevents rework. -

Marine-Grade Construction

Corrosion-resistant housings, quality shafts, and dependable impeller designs. -

Easy Serviceability

Pumps are designed for straightforward impeller replacement and routine maintenance. -

Real-World Cooling Performance

Proven flow rates meet the demands of marine heat exchangers and exhaust systems. -

Technical Support That Speaks Diesel

Mechanics get practical advice—not generic catalog answers—when troubleshooting cooling issues.

Bottom Line:

Whether you’re protecting capital assets, managing uptime across a fleet, or turning wrenches in the engine room, Diesel Pro Power raw water pumps deliver the reliability, fitment accuracy, and marine-grade durability required to keep engines cool and vessels working.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588