November 11, 2024

What is Valve Clearance In Detroit Diesel 149 Series Engines?

Step-by-Step Valve Clearance Adjustment Procedure For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

1. Prepare the Engine

2. Position the Cylinder

3. Measure Valve Clearance

4. Adjust Valve Clearance

5. Repeat for All Cylinders

6. Recheck Adjustments

Additional Notes for Mechanics

Read More

November 11, 2024

Overview

Step 1: Preparation

Safety First

Set Controls

Gather Required Tools

Step 2: Position the Cylinder for Adjustment

Identify the Cylinder

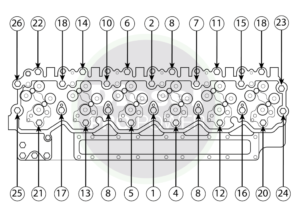

Firing Orders for 149 Series Configurations

Select the Starting Cylinder

Locate the Cylinder Position

Key Notes for Cylinder Identification

Rotate the Crankshaft

Verify Alignment

Tips for Accurate Positioning

Step 3: Attach the Injector Timing Gauge

Install the Timing Tool

Set Timing Dimensions

Tips for Accuracy

Step 4: Adjust the Injector Timing

Loosen the Locknut

Adjust the Plunger Height

Secure the Adjustment

Tips for Success

Step 5: Repeat for All Cylinders

Follow the Firing Order

Maintain Consistency

Post-Adjustment Checks

Start the Engine

Final Verification

Critical Tips for Success

Critical Notes for Mechanics

Precision is Key

Inspect Components

Document Adjustments

Temperature Considerations

Additional Tips for Mechanics

Read More

November 11, 2024

Step 1: Preparation

Safety First

Set Controls

Gather Required Tools

Step 2: Position the Cylinder for Adjustment

Identify the Cylinder

Firing Orders for 149 Series Configurations

Select the Starting Cylinder

Locate the Cylinder Position

Key Notes for Cylinder Identification

Rotate the Crankshaft

Verify Alignment

Tips for Accurate Positioning

Step 3: Attach the Injector Timing Gauge

Install the Timing Tool

Set Timing Dimensions

Tips for Accuracy

Step 4: Adjust the Injector Timing

Loosen the Locknut

Adjust the Plunger Height

Secure the Adjustment

Tips for Success

Step 5: Repeat for All Cylinders

Follow the Firing Order

Maintain Consistency

Post-Adjustment Checks

Start the Engine

Final Verification

Critical Tips for Success

Critical Notes for Mechanics

Precision is Key

Inspect Components

Document Adjustments

Temperature Considerations

Additional Tips for Mechanics

What is Valve Clearance?

Step-by-Step Adjustment Procedure

1. Prepare the Engine

2. Position the Cylinder

3. Measure Valve Clearance

4. Adjust Valve Clearance

5. Repeat for All Cylinders

6. Recheck Adjustments

Additional Notes for Mechanics

Read More

November 11, 2024

The Role of Cylinder Heads in Marine Engines

Creating the Combustion Chamber

Housing Essential Components

Impact on Engine Performance

New vs. Rebuilt Cylinder Heads

New Cylinder Heads

Advantages of New Cylinder Heads

Considerations for Purchasing New

Installation and Warranty

Rebuilt Cylinder Heads

Cost-Effectiveness of Rebuilt Heads

Performance Comparisons

Risks and Reliability

Popular Cummins Marine Engines and Their Cylinder Heads

QSC and QSB Series Cylinder Heads

6CTA and 6BTA Engine Cylinder Heads

Heavy-Duty Design

Performance Metrics

Repair and Replacement

KTA19, KTA38, and KTA50 Engine Cylinder Heads

Engineering Excellence

High-Power Applications

Durability and Longevity

QSM11 and QSK19 Model Cylinder Heads

Versatile Design

Efficiency and Performance

Maintenance and Upgrades

Choosing the Right Cylinder Head

Engine Model Compatibility

Usage and Application

Budget Considerations

Long-Term Maintenance

The Importance of a Head Gasket For Cylinder Heads On A Cummins Engine

Function of the Head Gasket

Consequences of Gasket Failure

Preventive Measures

Maintenance Tips for Cylinder Heads

Routine Inspections

Monitoring Coolant and Oil Levels

Professional Servicing and Upkeep

Addressing Wear and Tear

Real-World Applications of Cummins Engines

Commercial Vessels and Operations

Recreational Boats and Leisure Craft

Special Applications and Innovations

Conclusion

Read More

November 11, 2024

Components and Maintenance: Role of Exhaust Valves and Manifolds, Cleaning Buildup, and Ensuring Free Airflow

Exhaust Valves:

Exhaust Manifold:

Turbocharger (if equipped):

Exhaust Piping and Muffler:

Heat Shields and Insulation:

Inspection Tips: Detecting Exhaust Leaks or Valve Wear that Can Impact Engine Performance

Detecting Exhaust Leaks:

Inspecting Exhaust Valves for Wear:

Checking for Carbon Buildup:

Examining the Turbocharger (if applicable):

Inspecting Manifold and Pipe Connections:

Monitoring for Excessive Noise or Vibrations:

Read More

November 11, 2024

Why Torque Specs Are Important For Your Marine Diesel Engine Repairs

1. Preventing Engine Failure

2. Ensuring Proper Sealin

3. Maintaining Engine Efficiency

4. Prolonging Engine Life

5. Safety Considerations

6. Following Manufacturer Guidelines

Cummins Engine Torque Specs

Detroit Diesel Engine Torque Specs

Conclusion

Read More

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588