Introduction

The Cummins QSC 8.3 and QSL 9 engines are high-performance, durable diesel engines designed for marine, industrial, agricultural, and construction applications. These engines require routine maintenance and service to ensure they continue to perform at optimal levels. Regular maintenance not only extends engine life but also improves fuel efficiency, prevents unexpected breakdowns, and reduces repair costs.

This guide provides a detailed service schedule, essential routine inspections, and recommendations for fluids, filters, and lubrication to keep Cummins QSC 8.3 and QSL 9 engines operating at peak performance.

Parts Catalog for QSC 8.3 Cummins Marine and Industrial Engines

Parts Catalog for QSL 9 Cummins Marine and Industrial Engines

1. Recommended Service Schedule for Optimal Engine Performance

To maintain maximum efficiency and reliability, Cummins recommends a structured maintenance schedule based on operating hours, environmental conditions, and engine usage.

1.1 Daily Maintenance Checklist

Daily checks are essential for identifying potential issues early before they turn into costly repairs.

- Check engine oil level: Ensure oil levels are within the recommended range. Low oil levels can lead to engine wear and overheating.

- Inspect coolant level: Check the expansion tank and radiator for proper coolant levels.

- Inspect for fluid leaks: Look for any leaks from the fuel, oil, and coolant systems.

- Check belts and hoses: Inspect for wear, cracks, or loose connections.

- Monitor exhaust smoke color: Unusual smoke color (black, blue, or white) may indicate fuel or oil-related issues.

- Listen for abnormal noises: Knocking, rattling, or hissing sounds may indicate mechanical problems.

1.2 Service Intervals: 250 Hours or Monthly Maintenance

- Change engine oil and replace the oil filter.

- Inspect and clean air filters. Replace if heavily contaminated.

- Check and drain fuel/water separator. Water in fuel can cause injector damage.

- Inspect fuel filter for clogging or debris. Replace if necessary.

- Inspect coolant level and check for contamination.

- Check all belts and pulleys for wear or looseness.

- Inspect battery terminals and voltage levels.

1.3 Service Intervals: 500 Hours or Quarterly Maintenance

- Perform a full coolant system check. Flush and refill coolant if needed.

- Inspect the fuel system, including injectors and fuel pump, for leaks or clogging.

- Check the turbocharger for excessive wear or carbon buildup.

- Lubricate throttle linkages and moving components.

- Inspect electrical connections and wiring for corrosion or damage.

- Test alternator output and battery condition.

1.4 Service Intervals: 1,000 Hours or Annual Maintenance

- Adjust valve lash (valve clearance). Incorrect valve lash can reduce efficiency and damage the engine over time.

- Inspect the air intake system and replace the air filter if necessary.

- Perform engine compression testing to evaluate internal component wear.

- Flush and replace coolant.

- Check and replace engine mounts if worn.

- Update ECM software and diagnostic settings if applicable.

1.5 Service Intervals: 2,000 Hours or Bi-Annual Maintenance

- Replace water pump to prevent overheating issues.

- Perform a complete exhaust system inspection, checking for leaks or damage.

- Service the transmission (if applicable) and replace fluid.

- Perform a full electrical system inspection, including sensors, alternator, and starter motor.

- Test engine performance using diagnostic tools to check for hidden faults.

2. Routine Inspections and Adjustments

Routine inspections are critical to prevent major failures. These should be conducted at every service interval and before any long operating periods.

2.1 Valve Lash Inspection and Adjustment

- When to Adjust: Every 1,000 hours or if the engine experiences performance issues.

- Why it Matters: Improper valve clearance can cause poor combustion, excessive wear, and power loss.

- Procedure:

- Remove the valve cover and rotate the crankshaft to Top Dead Center (TDC).

- Use a feeler gauge to check clearance.

- Adjust using the lock-nut and adjuster screw method.

2.2 Turbocharger Inspection

- When to Inspect: Every 500 hours or when power loss is noticed.

- Key Inspection Points:

- Check for oil leaks or excessive carbon buildup in the intake.

- Ensure the turbine spins freely without resistance.

- Check for excessive shaft play, which can indicate wear.

Turbocharger & Related Components for Cummins QSC Engine

Turbocharger & Related Components for Cummins QSL Engine

2.3 Cooling System Inspection

- When to Inspect: Every 250 hours, with a full coolant flush at 1,000 hours.

- Common Issues:

- Low coolant levels causing overheating.

- Coolant contamination due to internal leaks.

- Corrosion in the radiator or heat exchanger.

- Preventative Maintenance:

- Use Cummins-approved coolant to prevent scaling.

- Replace hoses and clamps if signs of wear are found.

Fresh Water Pump & Related Components for Cummins QSC Engine

Fresh Water Pump & Related Components for Cummins QSL Engine

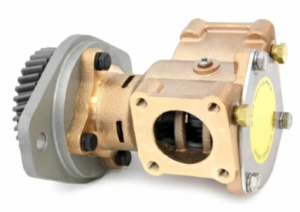

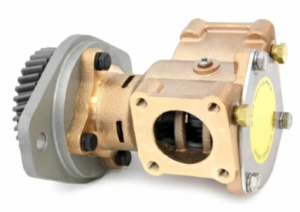

Marine Water Pump & Related Components for Cummins QSC Engine

Marine Water Pump & Related Components for Cummins QSL Engine

2.4 Fuel System Inspection

- When to Inspect: Every 500 hours, or when experiencing starting issues or power loss.

- Key Areas to Inspect:

- Fuel injectors for leaks or improper spray patterns.

- Fuel filter and water separator for clogging or contamination.

- Fuel pump for leaks or pressure loss.

Fuel Pump & Related Components for Cummins QSC Engine

Fuel Pump & Related Components for Cummins QSL Engine

3. Fluids, Filters, and Lubrication Requirements

The proper selection of fluids, filters, and lubricants plays a crucial role in the longevity and efficiency of Cummins QSC 8.3 and QSL 9 engines.

3.1 Engine Oil Requirements

- Recommended Oil Type:

- 15W-40 API CJ-4 or CK-4 for standard operating conditions.

- 5W-40 synthetic diesel oil for cold climates.

- Oil Change Intervals:

- 250 hours for normal-duty applications.

- 500 hours if using high-quality synthetic oils.

- Oil Capacity:

- QSC 8.3: 20-24 quarts.

- QSL 9: 24-28 quarts.

- Signs of Oil Issues:

- Thick or sludgy oil indicates contaminants or excessive soot buildup.

- Excessive oil consumption may indicate seal or gasket wear.

Oil Filter & Related Components for Cummins QSC Engine

Oil Filter & Related Components for Cummins QSL Engine

3.2 Fuel System Maintenance

- Primary Fuel Filter Replacement: Every 250 hours.

- Secondary Fuel Filter Replacement: Every 500 hours.

- Fuel Water Separator Draining: Weekly or at every fuel refill.

- Approved Fuel Types:

- Ultra-low sulfur diesel (ULSD) for Tier 4 Final emissions compliance.

- Biodiesel blends up to B20, with regular monitoring for fuel degradation.

Fuel Filter & Related Components for Cummins QSC Engine

Fuel Filter & Related Components for Cummins QSL Engine

3.3 Coolant Requirements

- Coolant Type:

- Use ethylene glycol-based extended-life coolant (ELC) with Cummins-approved additives.

- Avoid mixing different coolant brands, as it can cause chemical reactions.

- Coolant Replacement Intervals:

- Flush and replace coolant every 1,000 hours.

- Inspect and test coolant for pH balance and contaminant levels every 250 hours.

- Overheating Prevention:

- Ensure the coolant level remains above the minimum mark at all times.

- Check the water pump and thermostat for blockages or malfunctions.

Fresh Water Pump & Related Components for Cummins QSC Engine

Fresh Water Pump & Related Components for Cummins QSL Engine

Marine Water Pump & Related Components for Cummins QSC Engine

Marine Water Pump & Related Components for Cummins QSL Engine

Conclusion

Following a structured maintenance and service schedule for Cummins QSC 8.3 and QSL 9 engines is critical to achieving maximum performance, efficiency, and longevity. By adhering to routine inspections, fluid and filter changes, and proper lubrication practices, operators can prevent costly breakdowns and ensure optimal engine function.

For premium aftermarket parts, maintenance kits, and expert advice, visit Diesel Pro Power for high-quality components and support.

Parts Catalog for QSC 8.3 Cummins Marine and Industrial Engines

Parts Catalog for QSL 9 Cummins Marine and Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588