Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engines have earned a reputation for reliability, efficiency, and durability in various applications, including marine, industrial, trucking, agriculture, and construction. However, even the most robust engines require proper maintenance to ensure long service life and optimal performance.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

In this guide, we have explored critical maintenance practices, troubleshooting techniques, and best practices for rebuilding and storing Cummins B Series engines. This conclusion will provide:

✔ A summary of essential maintenance tips for long-term engine reliability.

✔ Final thoughts on keeping your Cummins B Series engine running at peak efficiency.

By following a disciplined maintenance schedule and using high-quality replacement parts, you can maximize engine lifespan, prevent costly breakdowns, and ensure optimal fuel efficiency.

Summary of Key Maintenance Tips

Proper maintenance is the foundation of a long-lasting engine. Below is a breakdown of the most critical maintenance areas for Cummins B Series engines.

1. Regular Oil and Lubrication Maintenance

✔ Change engine oil at recommended intervals (typically every 5,000 to 10,000 miles or 250-500 hours).

✔ Use high-quality diesel engine oil that meets or exceeds Cummins specifications.

✔ Replace oil filters during every oil change to prevent contaminants from damaging engine components.

✔ Check for oil leaks and monitor oil pressure to detect potential issues early.

✔ Proper oil and lubrication maintenance prevent excessive wear, improve efficiency, and extend engine life.

Oil Pump & Related Components for Cummins 4B Marine and Industrial Engines

Oil Pump & Related Components for Cummins 4BT Marine and Industrial Engines

Oil Pump & Related Components for Cummins 4BTA Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6B Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6BT Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6BTA Marine and Industrial Engines

2. Cooling System Maintenance

✔ Regularly check coolant levels and quality to prevent overheating and corrosion.

✔ Flush the cooling system and replace coolant according to the manufacturer’s recommendations.

✔ Inspect water pumps, thermostats, and radiator hoses for leaks or wear.

✔ Use a coolant mixture that meets Cummins specifications to avoid scale buildup.

✔ A properly maintained cooling system prevents overheating and reduces engine stress.

Fresh Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

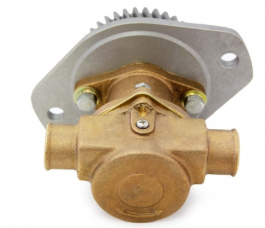

Marine Raw Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

3. Fuel System Maintenance

✔ Replace fuel filters at recommended intervals to maintain proper fuel flow.

✔ Use high-quality diesel fuel and add fuel stabilizers when storing the engine.

✔ Check for air in the fuel system and bleed it if necessary to prevent hard starts.

✔ Inspect injectors for clogging or wear and clean or replace them as needed.

✔ Monitor fuel pressure to ensure the lift pump and injection pump are functioning correctly.

✔ A clean fuel system ensures smooth engine operation, better combustion, and improved fuel efficiency.

Fuel Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Injector & Related Components for Cummins 4B Marine & Industrial Engines

Injector & Related Components for Cummins 4BT Marine & Industrial Engines

Injector & Related Components for Cummins 4BTA Marine & Industrial Engines

Injector & Related Components for Cummins 6B Marine & Industrial Engines

Injector & Related Components for Cummins 6BT Marine & Industrial Engines

Injector & Related Components for Cummins 6BTA Marine & Industrial Engines

4. Air Intake and Turbocharger Maintenance

✔ Replace air filters regularly to prevent dust and debris from entering the engine.

✔ Inspect the turbocharger for leaks or excessive play in the shaft.

✔ Check for boost leaks in intercooler pipes and clamps.

✔ Ensure the turbocharger is properly lubricated by monitoring oil pressure.

✔ Maintaining the air intake and turbocharger system maximizes power and fuel efficiency.

Turbocharger & Related Components for Cummins 6BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 6BTA Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BTA Marine & Industrial Engines

5. Exhaust System and Emissions Control

✔ Inspect the exhaust manifold and gaskets for leaks that could impact performance.

✔ Monitor diesel particulate filters (DPF) for clogging and clean or replace as necessary.

✔ Ensure the EGR valve (if equipped) is functioning properly to prevent excess emissions.

✔ Use ultra-low sulfur diesel (ULSD) if required for emissions compliance.

✔ A clean and well-maintained exhaust system ensures compliance with emissions regulations and enhances engine efficiency.

Exhaust & Related Components for Cummins 4B Marine & Industrial engine

Exhaust & Related Components for Cummins 4BT Marine & Industrial Engines

Exhaust & Related Components for Cummins 4BTA Marine & Industrial Engines

Exhaust & Related Components for Cummins 6B Marine & Industrial Engines

Exhaust & Related Components for Cummins 6BT Marine & Industrial Engines

Exhaust & Related Components for Cummins 6BTA Marine & Industrial Engines

6. Cylinder Head and Valve Adjustment

✔ Perform regular valve lash adjustments to maintain proper combustion timing.

✔ Inspect the cylinder head for cracks or warping that could indicate overheating issues.

✔ Check for blown head gaskets by looking for coolant in the oil or white smoke from the exhaust.

✔ Torque head bolts to manufacturer specifications to prevent head gasket failure.

✔ Proper cylinder head maintenance ensures optimal compression and engine efficiency.

Cylinder Head & Related Components for Cummins 6B Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BTA Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4B Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BTA Marine and Industrial Engines

7. Electrical System Maintenance

✔ Check battery voltage and charge levels to prevent weak starts.

✔ Inspect wiring connections for corrosion or loose terminals.

✔ Test alternators and voltage regulators to ensure proper charging.

✔ Replace glow plugs if the engine struggles to start in cold conditions.

✔ A strong electrical system ensures reliable starting and prevents unexpected breakdowns.

Starter & Alternator Related Components for Cummins 4B Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 4BT Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 4BTA Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6B Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6BT Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6BTA Marine & Industrial Engines

8. Preventive Maintenance for Long-Term Engine Health

✔ Monitor engine performance regularly to detect minor issues before they become major failures.

✔ Follow a strict maintenance schedule based on operating conditions and hours of use.

✔ Use only high-quality aftermarket or OEM-matching parts for replacements.

✔ Keep detailed maintenance records to track service history and prevent overlooked maintenance.

✔ Preventive maintenance is the key to minimizing downtime and extending engine lifespan.

Final Thoughts on Ensuring Long-Term Engine Reliability

A Cummins B Series engine, when properly maintained, can easily last beyond 500,000 miles or 20,000+ hours in many applications. The key to achieving maximum lifespan lies in regular maintenance, proper diagnostics, and using premium replacement parts.

Key Takeaways for Long-Term Reliability:

✔ Follow manufacturer-recommended service intervals for oil, filters, fuel system, and cooling system.

✔ Use high-quality aftermarket or OEM-equivalent components for replacements and overhauls.

✔ Keep an eye on common failure points, including head gaskets, turbochargers, and cooling components.

✔ Diagnose small issues early to prevent them from turning into costly repairs.

✔ Ensure proper storage procedures for engines that will be inactive for extended periods.

✔ Educate operators and mechanics on the best maintenance practices for Cummins B Series engines.

By committing to regular maintenance and proper care, you can:

✔ Maximize fuel efficiency and reduce operational costs.

✔ Minimize downtime and avoid unexpected failures.

✔ Extend the overall lifespan of your Cummins engine.

Looking Ahead: Keeping Your Cummins Engine in Top Shape

As technology advances and aftermarket innovations improve, Cummins B Series engine owners can take advantage of:

✔ Better fuel system components for cleaner combustion and lower emissions.

✔ Upgraded turbocharger options for increased efficiency and power output.

✔ Enhanced lubrication and coolant solutions to further extend engine life.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588