Cummins B Series engines are known for their durability, efficiency, and long lifespan. However, to ensure consistent performance, fuel efficiency, and reliability, regular maintenance is essential. A well-maintained Cummins engine can last 500,000 to 1,000,000 miles, making it a preferred choice for trucking, marine, industrial, construction, and agricultural applications.

This guide outlines recommended service intervals, the importance of using high-quality aftermarket parts, essential tools for servicing Cummins B Series engines, and common issues with preventive maintenance strategiesto keep your engine running at peak performance.

Parts Catalog for Cummins 4B Marine & Industrial Engines

Parts Catalog for Cummins 4BT Marine & Industrial Engines

Parts Catalog for Cummins 4BTA Marine & Industrial Engines

Parts Catalog for Cummins 6B Marine & Industrial Engines

Parts Catalog for Cummins 6BT Marine & Industrial Engines

Parts Catalog for Cummins 6BTA Marine & Industrial Engines

Recommended Service Intervals for Cummins B Series Engines

To maximize the lifespan and efficiency of your Cummins engine, it is essential to follow the recommended service intervals for routine maintenance tasks. The table below provides a general guideline based on hours of operation or mileage:

Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Maintenance Schedule

| Maintenance Task | Service Interval |

| Engine Oil & Filter Change | Every 250-300 hours or 6,000-10,000 miles |

| Fuel Filter Replacement | Every 10,000-15,000 miles or 500 hours |

| Air Filter Inspection | Every 10,000 miles or as needed (sooner in dusty environments) |

| Valve Lash Adjustment | Every 150,000 miles or 5,000 hours |

| Cooling System Flush | Every 2 years or 4,000 hours |

| Raw Water Pump Impeller (Marine Engines) | Every 200-300 hours |

| Turbocharger Inspection | Every 50,000 miles or 1,500 hours |

| Injector Inspection & Cleaning | Every 100,000 miles |

| Fuel Lift Pump Check | Every 25,000 miles |

| Battery & Electrical Check | Every 12 months |

By following these service intervals, you can prevent unexpected failures, excessive fuel consumption, and costly repairs.

Importance of Using High-Quality Aftermarket Parts

When servicing a Cummins B Series engine, using high-quality aftermarket parts is just as important as following proper service intervals. Cheap, low-quality parts can cause premature wear, reduced fuel efficiency, and mechanical failures.

Key Components Where Aftermarket Parts Matter

- Oil Filters & Fuel Filters

Oil Filter for Cummins 4B series

- Cheap filters may fail to remove contaminants effectively, leading to injector damage and excessive wear.

- High-quality filters improve fuel combustion efficiency and engine longevity.

Oil Filter & Related Components for Cummins 4B Marine and Industrial Engines

Oil Filter & Related Components for Cummins 4BT Marine and Industrial Engines

Oil Filter & Related Components for Cummins 4BTA Marine and Industrial Engines

Oil Filter & Related Components for Cummins 6B Marine and Industrial Engines

Oil Filter & Related Components for Cummins 6BT Marine and Industrial Engines

Oil Filter & Related Components for Cummins 6BTA Marine and Industrial Engines

- Air Filters

Airsep For Cummins 4BT

- Poor-quality air filters allow excessive dirt and dust into the engine, causing premature wear.

- High-performance filters improve turbocharger and engine efficiency.

Turbocharger & Related Components for Cummins 6BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 6BTA Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BTA Marine & Industrial Engines

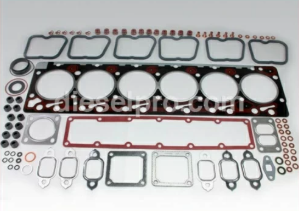

- Gaskets & Seals

New upper gasket set, for Cummins 6BT

- Subpar gaskets can fail under high pressure, leading to coolant or oil leaks.

- Premium-quality gaskets ensure proper sealing and extended durability.

Gaskets & Related Components for Cummins 4B Marine and Industrial Engines

Gaskets & Related Components for Cummins 4BT Marine and Industrial Engines

Gaskets & Related Components for Cummins 4BTA Marine and Industrial Engines

Gaskets & Related Components for Cummins 6B Marine and Industrial Engines

Gaskets & Related Components for Cummins 6BT Marine and Industrial Engines

Gaskets & Related Components for Cummins 6BTA Marine and Industrial Engines

- Pistons, Rings & Bearings

New piston kit, for use in Cummins 4B 3.9, 4BT 3.9, 4 BTA 3.9 6B 5.9, 6BT 5.9 6 BTA 5.9 engines.

- Inferior materials can cause early piston scuffing and bearing failures.

- High-quality aftermarket pistons extend engine life and reduce blow-by.

Piston Kit & Related Components for Cummins 4B Marine and Industrial EnginesPiston Kit& Related Components for Cummins 4BT Marine and Industrial Engines

Piston Kit& Related Components for Cummins 4BTA Marine and Industrial Engines

Piston Kit& Related Components for Cummins 6B Marine and Industrial Engines

Piston Kit & Related Components for Cummins 6BT Marine and Industrial Engines

Piston Kit & Related Components for Cummins 6BTA Marine and Industrial Engines

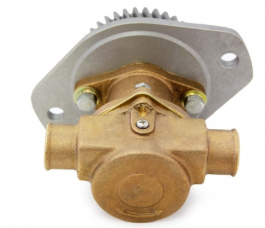

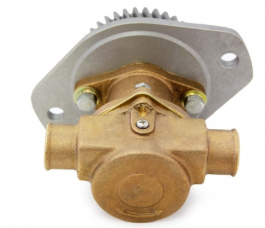

- Raw Water Pump (Marine Engines)

Marine Water Pump for Cummins 6BT Series Marine Engines

- Using low-quality impellers in marine raw water pumps can lead to premature failure.

- High-quality impellers ensure continuous cooling and prevent overheating.

Marine Raw Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Why High-Quality Parts Matter

✔ Extended engine lifespan

✔ Improved reliability and performance

✔ Reduced long-term maintenance costs

✔ Better fuel efficiency

Investing in high-quality aftermarket parts ensures your Cummins B Series engine runs optimally for years to come.

Essential Tools for Servicing Cummins B Series Engines

Servicing Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engines requires the right tools. Having high-quality, professional-grade tools ensures precise adjustments and proper repairs.

Must-Have Tools for Cummins Engine Maintenance

- Torque Wrench – Ensures proper torque on cylinder head bolts, main bearings, and rod bearings.

- Feeler Gauge – Required for accurate valve lash adjustments.

- Oil Filter Wrench – Helps remove and install oil filters without damaging seals.

- Fuel Pressure Gauge – Diagnoses fuel pressure issues with lift pumps and injectors.

- Compression Tester – Checks cylinder compression to identify wear on pistons and rings.

- Multimeter – Essential for diagnosing electrical and battery issues.

- Infrared Thermometer – Detects overheating and cooling system inefficiencies.

- Cooling System Pressure Tester – Identifies leaks in the radiator, hoses, and water pump.

- Injector Removal Tool – Allows for safe injector replacement without damaging components.

- Raw Water Pump Impeller Puller (Marine Engines) – Makes it easy to remove and replace raw water pump impellers.

Equipping yourself with the right tools reduces downtime and ensures professional-quality repairs.

Common Issues and Preventive Maintenance Strategies

Regular preventive maintenance is the best way to avoid costly engine repairs. Below are some of the most common issues faced by Cummins B Series owners and the best ways to prevent them.

1. Overheating Issues

Symptoms:

- Rising coolant temperatures

- Coolant loss

- Steam or boiling coolant

Causes:

✔ Clogged radiator or heat exchanger

✔ Failing thermostat

✔ Raw water pump impeller failure (marine engines)

✔ Coolant leaks or air bubbles in the system

Preventive Maintenance:

✔ Flush and replace coolant every two years

✔ Inspect hoses and water pumps regularly

✔ Change raw water pump impeller every 200-300 hours

Fresh Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

2. Fuel System Issues

Symptoms:

- Hard starting or rough idling

- Loss of power under load

- White or black smoke from exhaust

Causes:

✔ Clogged fuel filters

✔ Failing injectors

✔ Air leaks in fuel lines

✔ Weak lift pump

Preventive Maintenance:

✔ Replace fuel filters every 10,000-15,000 miles

✔ Bleed air from the fuel system

✔ Test lift pump pressure every 25,000 miles

Fuel Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Injector & Related Components for Cummins 4B Marine & Industrial Engines

Injector & Related Components for Cummins 4BT Marine & Industrial Engines

Injector & Related Components for Cummins 4BTA Marine & Industrial Engines

Injector & Related Components for Cummins 6B Marine & Industrial Engines

Injector & Related Components for Cummins 6BT Marine & Industrial Engines

Injector & Related Components for Cummins 6BTA Marine & Industrial Engines

3. Excessive Oil Consumption

Symptoms:

- Frequent need to top off oil

- Blue smoke from exhaust

Causes:

✔ Worn piston rings or valve seals

✔ Leaking gaskets or seals

✔ Oil dilution due to incomplete combustion

Preventive Maintenance:

✔ Use high-quality engine oil and replace it every 250-300 hours

✔ Inspect turbo seals and valve guides

Oil Pump & Related Components for Cummins 4B Marine and Industrial Engines

Oil Pump & Related Components for Cummins 4BT Marine and Industrial Engines

Oil Pump & Related Components for Cummins 4BTA Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6B Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6BT Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6BTA Marine and Industrial Engines

4. Loss of Turbo Boost (Turbocharged Engines)

Symptoms:

- Reduced power output

- Black smoke under acceleration

- Hissing sounds from the intake

Causes:

✔ Boost leaks from worn intercooler hoses

✔ Failing turbocharger bearings

✔ Dirty or clogged air filter

Preventive Maintenance:

✔ Check turbo connections every 50,000 miles

✔ Replace air filters every 10,000 miles

Turbocharger & Related Components for Cummins 6BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 6BTA Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BTA Marine & Industrial Engines

5. Electrical and Battery Failures

Symptoms:

- No start or slow cranking

- Intermittent shutdowns

Causes:

✔ Weak battery or corroded terminals

✔ Alternator failure

✔ Loose engine ground connections

Preventive Maintenance:

✔ Check battery voltage every 12 months

✔ Clean battery terminals to prevent corrosion

Starter & Alternator Related Components for Cummins 4B Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 4BT Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 4BTA Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6B Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6BT Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6BTA Marine & Industrial Engines

Final Thoughts

Regular preventive maintenance is the key to ensuring long-term reliability for your Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engines. By following service intervals, using high-quality parts, equipping yourself with the right tools, and addressing common issues proactively, you can:

✔ Extend the life of your engine

✔ Improve fuel efficiency

✔ Prevent expensive breakdowns

Parts Catalog for Cummins 4B Marine & Industrial Engines

Parts Catalog for Cummins 4BT Marine & Industrial Engines

Parts Catalog for Cummins 4BTA Marine & Industrial Engines

Parts Catalog for Cummins 6B Marine & Industrial Engines

Parts Catalog for Cummins 6BT Marine & Industrial Engines

Parts Catalog for Cummins 6BTA Marine & Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588