Introduction: Why the Output Shaft and Bearings Deserve Special Attention

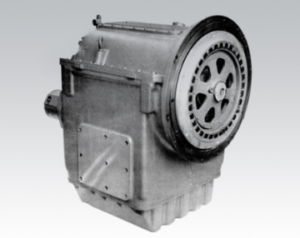

The Twin Disc MG527 Marine Gear is a high-performance marine transmission that demands precise alignment, consistent lubrication, and strong component integrity to deliver years of dependable service. Among its critical components, few experience more continuous strain than the output shaft and its associated bearings. These elements are directly responsible for transferring rotational torque from the engine, through the gear, to the propeller shaft—sustaining vibration, thrust load, and direction changes.

Regular inspection and proactive servicing of the output shaft and bearings prevent severe mechanical failures, reduce vessel downtime, and maintain peak operating performance. Left unchecked, minor wear in these areas can snowball into catastrophic failure, damaging surrounding components, increasing repair costs, and putting your vessel at risk of a complete transmission lockup while underway.

In this guide, we’ll walk you through how to inspect output bearings for wear, how to recognize vibration-related symptoms, how to safely remove and examine bearings, and how to replace the output shaft seal when wear or leakage appears. This hands-on, practical walkthrough provides a level of detail rarely found outside of factory-certified training—making it a must-read for fleet mechanics, commercial vessel operators, and independent boat owners alike.

Parts Catalog for Twin Disc MG527 Marine Transmissions

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Section 1: Bearing Wear Inspection for Twin Disc MG527

The output shaft bearings support the full load of rotational torque and alignment between the transmission output and the propeller shaft. Over time, even with proper lubrication, these bearings can suffer wear due to vibration, high RPMs, saltwater intrusion, dirty oil, or misalignment.

What Bearings Are Used in the MG527 Output Assembly?

While bearing types can vary slightly by MG527 sub-model, most are heavy-duty tapered roller bearings or deep groove ball bearings, designed to:

- Handle axial thrust (from the propeller’s push/pull)

- Support radial loads (from torque and shaft weight)

- Operate under fluctuating oil temperatures

- Maintain minimal play to reduce vibration and noise

Signs of Output Bearing Wear in Marine Transmissions

1. Vibration at Specific RPM Ranges

This is one of the first symptoms. If vibration increases as RPM increases—or appears suddenly around a specific speed—it may indicate:

- Worn or spalled bearing surfaces

- Shaft imbalance caused by bearing looseness

- Poor alignment due to deteriorating races

Check for:

- Vibration in the deck or engine room near the transmission

- Buzzing or humming sound that increases with throttle

- Resonance felt when changing from forward to reverse

2. Metallic Debris in Oil

Oil sampling and filter inspections are valuable tools for diagnosing bearing wear.

Look for:

- Silver glitter in oil = bearing cage or roller deterioration

- Gray sludge = friction plate or bearing degradation

- Metal flakes on magnetic drain plugs

3. Noise From Rear of Transmission

A bearing in distress may emit:

- A whining noise (especially under load)

- Growling or grinding at idle

- Clunking when shifting from forward to reverse

Use a mechanic’s stethoscope or sound probe to isolate the noise. If sound amplifies near the output housing, suspect the bearings.

4. Abnormal Shaft Movement

Excessive end play or radial movement indicates that the bearings are no longer supporting the shaft correctly.

Symptoms include:

- Shaft “clicking” or “thumping” when shifted

- Difficulty keeping engine alignment

- Propeller shaft pushing into coupling

How to Inspect Output Bearings Without Full Disassembly

- Secure Vessel and Shut Down Engine

Let the transmission cool. Secure the shaft so it won’t move unexpectedly.

- Access the Output Coupling

Remove shaft guards or covers. Inspect for oil stains or signs of misalignment.

- Manually Check Shaft Play

Try to push/pull the shaft inline (axial) and then wiggle it side to side (radial). Movement over 0.010 inches (0.25 mm) can indicate bearing wear.

- Dial Indicator Check

Mount a magnetic base on the gear housing with a dial indicator touching the shaft end. Record movement du

ring push/pull tests.

- Check Oil Sample

Take a midstream sample (not first or last of drain) and send to a lab. Spectrographic results will reveal high iron or chromium content from bearing wear.

Section 2: How to Safely Remove and Inspect Bearings In Twin Disc MG527 Marine Gears

If bearing wear is confirmed, the next step is safe removal. The MG527’s output bearing sits in a load-bearing housing that may require moderate disassembly to access.

Safety First

Before working:

- Disconnect power from the vessel’s batteries

- Secure the propeller shaft

- Ensure workspace is clean, dry, and well-lit

- Wear safety goggles and oil-resistant gloves

Tools You’ll Need

- Bearing puller or internal bearing extractor

- Soft mallet

- Torque wrench

- Feeler gauges

- Shop press (optional for reinstallation)

- Clean parts trays

- High-temp bearing grease

- Dial indicator

- Parts cleaner or brake cleaner

- Bearing heater (optional but helpful)

Step-by-Step: Removing the Output Bearing

- Drain the Transmission Oil

Fully drain the oil before opening any housings.

- Remove Output Shaft Coupling

Unbolt the coupling from the shaft. Use a puller to remove it from a tapered or keyed shaft, marking alignment for reassembly.

- Remove Rear Housing or Bearing Cap

Unbolt and gently pry off the bearing cap or rear housing cover. Support it as you remove—this piece may be heavy.

- Inspect Housing Interior

Check for metal shavings, broken bearing pieces, or discolored oil residue. Clean the area with solvent.

- Remove Bearing

Use a puller or extractor to pull the bearing off the shaft. If it’s stuck, apply penetrating oil and try light tapping with a mallet.

- Inspect the Shaft

Look for grooves, pitting, or discoloration where the bearing rides. Use a micrometer to check for shaft wear.

Bearing Inspection Checklist

| Component | What to Look For | Pass/Fail |

| Outer Race | Smooth, no grooves or pitting | Fail if scored |

| Inner Race | No signs of spinning on shaft | Fail if blue/discolored |

| Rollers | Uniform size, no flats or chips | Fail if uneven |

| Cage | Not cracked or loose | Fail if deformed |

| Fit on Shaft | Snug but not tight (check specs) | Fail if loose |

Tip: Always replace bearings in pairs. If one fails, the other is not far behind.

Reinstallation Notes

- Use a bearing heater or warm oil bath to slightly expand bearing before reinstalling (never use direct flame).

- Press bearing evenly using a shop press or correct driver.

- Lightly lubricate all surfaces before final install.

- Reinstall rear cover using proper torque specs in a crisscross pattern.

Section 3: Output Shaft Seal Replacement For Twin Disc MG527 Marine Gears

The output shaft seal prevents gear oil from leaking at the point where the shaft exits the gear case. Over time, seals wear out due to:

- Constant rotation

- Exposure to contaminated oil

- Shaft misalignment

- Saltwater corrosion

- Thermal cycling

A damaged seal can lead to:

- Oil drips in the bilge

- Low oil levels during checks

- Slipping or overheating

- Water intrusion (if submerged prop shaft pressure reverses seal flow)

Symptoms of Seal Wear

- Wetness around the base of the output coupling

- Drips forming on shaft tunnel cover

- Transmission oil level dropping slowly over time

- Noise during gear engagement or throttle up

- Propeller shaft movement causing side loading

Tools You’ll Need

- Seal puller or flathead screwdriver

- Replacement output shaft seal (correct size for MG527)

- Seal driver or appropriate-sized socket

- Marine-grade transmission oil

- Clean rags and parts cleaner

- Shop press or hammer (light taps only)

Step-by-Step: Seal Removal and Replacement

- Drain the Oil

Fully drain the gearbox to avoid spills during seal removal.

- Remove the Output Coupling

Disconnect shaft and coupling. Use a puller if necessary.

- Access the Seal

With the coupling removed, the seal will be exposed in the bore.

- Remove the Old Seal

Use a seal puller or carefully work it out with a screwdriver. Avoid damaging the bore surface.

- Clean the Area Thoroughly

Remove all old sealant or debris. Inspect the bore and shaft surface for corrosion or scoring.

- Install the New Seal

- Lightly coat the new seal’s lip with oil.

- Tap evenly into place using a driver or appropriate socket.

- Ensure seal sits flush—do not install crooked or overdriven.

- Reinstall the Coupling

Line up with previous marks, torque to proper spec.

- Refill Transmission Oil

Use approved oil and fill to correct level. Run engine at idle and check for leaks.

Post-Service Checklist

- Recheck shaft play

- Confirm coupling torque

- Monitor oil level for next 3–5 hours of operation

- Use a white paper towel below housing to spot small leaks

- Reinspect after next sea trial

Recommended Parts for MG527 Output Service

When replacing seals and bearings, always choose high-quality or OEM-compatible components. Recommended parts may include:

- Output shaft bearing (inner and outer, if paired)

- Output shaft oil seal

- Rear bearing housing gasket or O-ring

- Gear oil (SAE 30 or 40, depending on vessel specs)

- Rebuild kits (clutch, gasket, seal kits sold by aftermarket suppliers like Diesel Pro Power)

Routine Maintenance Schedule: Output Shaft & Bearings

| Task | Frequency |

| Visual shaft seal check | Every 100 hours |

| Shaft play inspection | Every 250 hours |

| Oil sampling | Every 500 hours |

| Bearing removal & inspection | Every 1000 hours |

| Seal replacement | As needed or every 2,000–3,000 hours |

Conclusion: Extend the Life of Your MG527 With Proactive Output Maintenance

The output shaft and bearing assembly of the Twin Disc MG527 Marine Gear is one of the most important—and most abused—systems in your vessel’s propulsion chain. From intense torque to shock loading, these components operate in conditions few automotive or industrial bearings ever experience.

By developing a routine inspection habit, learning to interpret early warning signs, and conducting seal and bearing service as needed, you can avoid:

- Gearbox overheating

- Shaft misalignment

- Seal blowouts

- Total transmission failure

The result? Less downtime, fewer emergency repairs, and a longer service life for your MG527. Whether you’re running a tugboat, a passenger vessel, or a commercial fishing operation, protecting your output assembly is a critical part of keeping your vessel—and your business—moving forward.

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588