Introduction: Why Oil Selection and Maintenance Are Mission-Critical

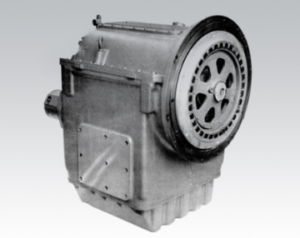

The Twin Disc MG527 Marine Gear is a precision-engineered marine transmission that operates under heavy loads, fluctuating RPMs, and constant hydraulic pressure. At the center of its performance and longevity is the quality and management of its lubrication system. Choosing the correct oil type, performing timely fluid changes, and understanding how to properly maintain oil levels are essential steps to protect your investment.

Parts Catalog for Twin Disc MG527 Marine Transmissions

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Oil doesn’t just lubricate the MG527—it also provides:

- Hydraulic actuation for clutch engagement

- Cooling to dissipate heat

- Cleaning to suspend debris

- Corrosion protection for internal components

This guide dives deep into oil and fluid specifications, including the difference between mineral and synthetic oils, fluid capacity details, proper change procedures, and how to ensure you’re always operating with the correct fluid level.

Whether you’re a fleet mechanic, marine engineer, or hands-on boat owner, this is your go-to resource for optimizing the lubrication system of your MG527 marine gear.

Section 1: Approved Oil Types for Twin Disc MG527

Selecting the correct oil isn’t just about meeting minimum specs—it’s about choosing a lubricant that performs reliably under the specific demands of marine duty cycles, which include:

- High torque at low RPM

- Prolonged idling and slow-speed maneuvering

- Sudden acceleration or direction changes

- Heat buildup in confined engine compartments

- Exposure to saltwater and humidity

Marine Transmission Fluid Specifications

According to field-tested standards and manufacturer guidance, the MG527 is compatible with:

- SAE 30 or SAE 40 weight engine oils that meet API classifications CF, CF-2, or CG-4

- Marine-grade ATF (Automatic Transmission Fluid) in certain low-load or low-temperature environments

- Synthetic transmission fluids that meet or exceed Twin Disc heat and pressure ratings

Recommended Mineral Oils (Non-Synthetic)

Mineral oils are petroleum-based fluids commonly used in marine gearboxes due to their:

- Cost-effectiveness

- Compatibility with clutch materials

- Stable viscosity in moderate climates

- Predictable thermal expansion

Examples of high-quality mineral oils:

- Chevron Delo 400 SAE 30 or 40

- Shell Rotella T1 SAE 30 or 40

- Mobil Delvac 1300 Super SAE 40

Use mineral oil if:

- Your vessel operates in temperate or tropical environments

- You perform regular oil changes (every 250–300 hours)

- You have an older MG527 with original clutch friction material

- Your oil cooler system is clean and efficient

Synthetic Oils: Pros and Cons

Synthetic oils are engineered for high performance and extreme temperature tolerance. They’re made from refined base stocks and contain advanced additive packages that enhance:

- Oxidation resistance

- Thermal stability

- Shear strength

- Wear protection

Recommended synthetic fluids:

- Mobil SHC 630

- Amsoil Marine SAE 40 Synthetic

- Royal Purple Max Gear SAE 30/40

Use synthetic oil if:

- Your gear operates at continuous high RPMs or in heavy commercial use

- Your vessel runs in cold climates where startup viscosity matters

- You’re aiming for extended oil change intervals (with oil analysis)

- You’ve upgraded to modern friction materials or seal kits

Caution: Synthetic oils can cause older seals to shrink or leak if the system wasn’t previously running synthetic. Always monitor for leaks after switching.

Automatic Transmission Fluid (ATF) Use

In select cases (e.g., light-duty vessels with low clutch loading), Dexron III/Mercon spec fluids may be used. ATF is lower in viscosity than engine oil and offers fast clutch fill times in cold starts.

Use ATF only if:

- The MG527 is used in recreational, low-load applications

- Ambient temps are low

- Recommended by Twin Disc or your rebuild technician

Oil Selection Tips

- Always match viscosity to temperature range (see oil charts)

- Never mix synthetic and mineral oils without a full flush

- Do not use oils with friction modifiers (designed for limited-slip diffs or engine friction reduction)

- Avoid “universal oils” unless proven in marine transmissions

- Monitor your oil with regular analysis for wear metals and oxidation

Section 2: Fluid Capacity and Change Procedures For Twin Disc MG527 Marine Gears

The MG527 holds a considerable amount of oil, which must be managed carefully to ensure lubrication, hydraulic function, and heat dissipation are maintained.

Estimated Oil Capacity

| Component | Capacity |

| Transmission only | 2.5–4.0 gallons (9.5–15.1 liters) |

| Transmission + Cooler + Lines | Up to 5.0 gallons (19 liters) total |

Always refer to your specific MG527 variant and oil cooler configuration to confirm actual capacity. Measure oil during refill rather than relying on estimates.

When to Change the Oil

| Condition | Interval |

| Light recreational use | Every 250 engine hours or once per season |

| Commercial use (daily ops) | Every 200–250 hours |

| Heavy load or high temp operation | Every 150–200 hours |

| After overheating or oil contamination | Immediately |

| After major repair or rebuild | 10-hour break-in change, then standard interval |

Step-by-Step: How to Drain and Replace Transmission Oil

✅ Step 1: Warm the Gearbox

- Start engine and idle until oil reaches 100°F (38°C) or higher

- Warmer oil flows faster and carries more suspended debris

- Shut engine down and wait 10–15 minutes

✅ Step 2: Position Drain Pan or Vacuum Extractor

- Place drain pan under transmission (if vessel is out of water)

- Or insert vacuum tube down dipstick/fill port for in-water service

✅ Step 3: Remove the Drain Plug (If Equipped)

- Slowly remove plug with absorbent pads nearby

- Allow full drain—at least 20–30 minutes

- Inspect oil:

- Check for metal flakes

- Smell for burnt odor

- Note color and clarity

✅ Step 4: Remove and Inspect Filter or Screen

- Remove side-mounted spin-on filter (if present)

- Clean internal filter screens with solvent and lint-free rag

- Replace filter element or gasket if degraded

✅ Step 5: Clean Drain Plug and Magnet

- Many drain plugs include a magnet—wipe clean

- Check for unusual debris

- Replace crush washer or sealing gasket

✅ Step 6: Reinstall Drain Plug and Filter

- Torque plug to specification

- Reinstall cleaned or new filter

- Confirm all connections are tight and dry

Step-by-Step: How to Refill Transmission Oil

✅ Step 1: Choose Correct Oil

- Select SAE 30 or 40 based on environment

- Confirm synthetic vs mineral decision

- Have enough volume on hand (5 gallons minimum)

✅ Step 2: Add Oil Through Fill Port

- Slowly pour in oil using clean funnel

- Add 75–80% of estimated total capacity

- Let settle for 10 minutes

✅ Step 3: Check Oil Level

- Insert dipstick and read oil level

- Do not overfill—oil expands when hot

✅ Step 4: Start Engine and Circulate Oil

- Idle in neutral for 3–5 minutes

- Shift through forward and reverse several times

- Watch for pressure build and any leaks

- Check fluid color and level again

✅ Step 5: Final Top-Off and Check

- After engine is warm, perform final dipstick check

- Add oil until level is at max line (do not exceed)

- Clean dipstick, cap, and surrounding area

Dipstick Reading Best Practices

- Always check oil when engine is warm and idling

- Vessel must be level fore and aft

- Dipstick must be wiped clean before insertion

- Do not rely on cold readings

- Recheck oil after first sea trial or hard throttle

Section 3: Oil Monitoring and Condition Analysis For Twin Disc MG527 Marine Gears

Oil doesn’t last forever—even the best fluids break down under heat and pressure. Monitoring oil condition can help prevent catastrophic failure before it happens.

Visual Inspection Tips

- Amber to light brown = good

- Dark brown = oxidized, change soon

- Black with debris = clutch material or heavy contamination

- Milky or cloudy = water contamination

- Metallic sheen = bearing or gear wear

Oil Analysis Services

Use oil analysis labs to check for:

- Wear metals (iron, copper, aluminum)

- Water content

- Viscosity degradation

- Oxidation and additive breakdown

Send a sample:

- Every 500–1,000 hours for commercial use

- Whenever contamination or heat is suspected

- At season’s end before winter lay-up

Labs like Blackstone, Polaris, or your local distributor can offer deep insights for less than $40/sample.

Oil Sampling Procedure

- Use mid-drain sample (not beginning or end)

- Label with engine hours and oil type

- Ship in lab-provided container

- Compare results to prior samples for trend analysis

Common Mistakes to Avoid

| Mistake | Why It’s a Problem |

| Overfilling | Causes foaming, pressure drop, clutch slippage |

| Using wrong oil type | Leads to seal incompatibility, heat buildup |

| Not changing filter | Allows debris to recirculate, clogs valve body |

| Mixing oil types | Causes chemical instability, seal swelling |

| Ignoring water intrusion | Leads to corrosion, clutch failure |

Seasonal Oil Management Tips

- Before winter: Change oil to remove acids and water, prevent corrosion

- Before launch: Check level and clarity, top off as needed

- After long idle: Run engine and recheck oil for condensation or contamination

- Use labels: Note oil type, change date, and hours on dipstick tube or nearby panel

Conclusion: The Right Oil Makes All the Difference

In marine gearboxes like the Twin Disc MG527, the oil is more than just a lubricant—it’s the system’s lifeblood. It drives clutch performance, cools vital components, and protects high-torque gear assemblies.

By following the guidance in this article, you’ll ensure:

- Clean, compatible oil is always in use

- Fluid levels are checked correctly and consistently

- Oil is changed before degradation damages internal parts

- Your gearbox runs longer, quieter, and more reliably

Don’t guess—get it right the first time. The result is a smoother gear, fewer repairs, and more peace of mind when you’re miles offshore.

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588