Introduction: Why Proper Service Matters for the Twin Disc MG527 Marine Gear

- Overview of the MG527’s role in marine propulsion systems

- Importance of routine maintenance for longevity and performance

- Brief summary of what this guide covers

- Disclaimer: For torque values, rebuild steps, and more technical data, always refer to the OEM service manual

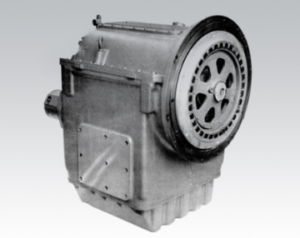

Understanding the Twin Disc MG527 Marine Gear

Key Specifications and General Overview

- Input power, RPM ratings, and torque capacity

- Gear ratios available

- Applications in commercial and recreational vessels

Component Layout and Function

- Brief walkthrough of the MG527’s major components

- Role of the hydraulic clutch, reduction gearing, and control valve

Tools and Safety Equipment Needed for Servicing the MG527

Required Tools

- Basic hand tools

- Torque wrenches

- Alignment tools

- Specialty tools (if applicable)

Personal Protective Equipment (PPE)

- Gloves, safety goggles, steel-toed boots

- Oil-resistant clothing

- Fire extinguisher near the work area

Routine Maintenance Checklist for the Twin Disc MG527 Marine Gear

Daily/Pre-Trip Inspections

- Oil level checks

- Visual inspection for leaks

- Shift engagement and operational feel

Scheduled Maintenance (250, 500, 1000-hour intervals)

- Oil change intervals and type of oil

- Filter inspections and replacements

- Bolt torque checks

- Heat exchanger flushing and cleaning

Servicing the Hydraulic System For The Twin Disc MG527 Marine Gear

Hydraulic Pressure Checks

- Proper test points

- Acceptable pressure ranges

Hydraulic Clutch Inspection and Adjustment

- Signs of wear

- Proper clearance and pressure plate inspection

Inspection and Service of the Output Shaft and Bearings For The Twin Disc MG527 Marine Gear

Bearing Wear Inspection

- Vibration signs

- How to remove and inspect bearings safely

Output Shaft Seal Replacement

- Common signs of wear (oil seepage, noise)

- Step-by-step replacement overview (without breaching copyright)

Gearbox Disassembly and Reassembly Overview For The Twin Disc MG527 Marine Gear

Refer to OEM service manual for full disassembly/reassembly instructions

Preparatory Steps

- Draining oil

- Tagging lines and connectors

Accessing Internal Components

- Removing covers, couplings, and linkages

- Safety tips for handling heavy parts

Reassembly Best Practices

- Cleanliness and proper lubrication

- Bolt torque importance

Adjustments and Calibration Procedures For The Twin Disc MG527 Marine Gear

Shift Timing Adjustment

- Proper shifting speed and timing for smooth operation

Control Cable and Linkage Calibration

- Ensuring full travel and no slack

- Lubrication of control linkage

Common Issues and Troubleshooting the Twin Disc MG527 Marine Gear

Slipping or Delayed Engagement

- Potential causes (low pressure, worn clutches)

- Quick diagnosis checklist

Unusual Noises or Vibrations

- What different sounds might indicate

- Inspection points to focus on

Overheating

- Causes (low oil, heat exchanger blockages)

- Step-by-step cooling system inspection

Oil and Fluid Recommendations For The Twin Disc MG527 Marine Gear

Approved Oil Types

- Marine transmission fluid specs

- Synthetic vs mineral oil considerations

Fluid Capacity and Change Procedures

- How to properly drain and refill

- Oil level verification

Tips for Extending the Life of For The Twin Disc MG527 Marine Gear

Using only high-quality parts and fluids

- Running the gear at optimal load conditions

- Seasonal inspection routines

- Storage preparation during off-season

Parts Support and Rebuild Kit Availability For The Twin Disc MG527 Marine Gear

Parts Catalog for Twin Disc MG527 Marine Transmissions

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

- Recommended aftermarket suppliers (e.g., Diesel Pro Power)

- Benefits of aftermarket kits over OEM in availability and cost

- Components included in a typical rebuild kit

50 Frequently Asked Questions (FAQ) For The Twin Disc MG527 Marine Gear

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Please follow and like us:

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588