Key Topics Covered

- Practical Guide To Servicing Cummins C Series Engines (1991 and 1994 Certification Levels) 6C, 6CT, 6CTA

- Practical Guide to Servicing Your Cummins KTA19

- Practical Guide to servicing Cummins ISB & QSB

- Practical Guide to Servicing Your Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

- Practical Guide to Servicing Cummins ISM, ISMe, and QSM11 Engines

- Practical Guide to Servicing Your Cummins N14 Engine

- Practical Guide to the Operation & Maintenance of Cummins KTA38 & KTA50 Engines

- Practical Guide To Servicing Cummins QSC 8.3 & QSL 9 Engines

Introduction

From rugged tugboats to reliable power generation stations, Cummins engines are at the heart of marine and industrial operations around the globe. Known for their reliability, broad range, and ease of serviceability, Cummins diesel engines are a preferred choice for commercial fleet owners, independent mechanics, and vessel operators alike. But keeping them running at peak efficiency takes more than routine oil changes—it takes knowledge, timing, and a solid maintenance strategy.

This guide, Practical Guides To Servicing Cummins Marine & Industrial Engines, compiles and links to the essential service guides for the most common Cummins engine platforms. These individual articles are designed as high-level, actionable walkthroughs for practical servicing tasks. Whether you’re working with legacy mechanical models like the 6BT or modern Tier-rated electronic engines like the QSM11, this guide is your first stop to understanding what to expect before you turn a wrench.

⚠️ Disclaimer: These practical guides are intended as a supplement to—but not a replacement for—OEM service manuals. Always refer to the official Cummins manual for technical data, torque specs, calibration settings, and safety precautions.

1. Cummins C Series (6C, 6CT, 6CTA – 1991 & 1994 Certification Levels)

📘 Practical Guide To Servicing Cummins C Series Engines

- 1991 vs 1994 certification differences

- Cooling system flushing procedures

- Turbo inspection and troubleshooting

- Raw water pump maintenance

- Injector wear symptoms and servicing

- CPL number decoding

- Cylinder head service walkthrough

2. Cummins KTA19

📘 Practical Guide to Servicing Your Cummins KTA19

- Engine disassembly/assembly steps

- PT fuel system and injector timing

- Oil pressure loss and cooler cleaning

- Coolant management

- Rebuild kit preparation

- Liner inspection and compression checks

3. Cummins ISB & QSB

📘 Practical Guide to Servicing Cummins ISB & QSB

- EGR, SCR, and DPF system overview

- Fuel rail and injector troubleshooting

- Oil change schedules and sensor checks

- Safe engine start/stop practices

- Fuel contamination prevention

4. Cummins B Series (6B, 6BT, 6BTA, 4B, 4BT, 4BTA)

📘 Practical Guide to Servicing Your Cummins B Series Engines

- Model differences: 4 vs. 6 cylinders

- Turbo and exhaust maintenance

- Fuel lift pump diagnostics

- Valve lash and timing setup

- Marine heat exchanger service

5. Cummins ISM, ISMe & QSM11

📘 Practical Guide to Servicing Cummins ISM, ISMe, and QSM11 Engines

- Fuel injector and ECM diagnostics

- Harness and fault code reading

- Compression tests and turbo boost checks

- Valve and rocker arm service

- Sea trial load testing

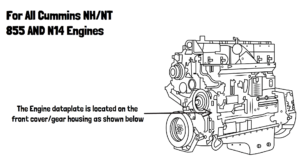

6. Cummins N14

📘 Practical Guide to Servicing Your Cummins N14 Engine

- Celect vs. Celect Plus features

- Fuel solenoid and injector calibration

- Turbo and governor tuning

- Troubleshooting smoke and misfires

- Timing gear rebuilds

7. Cummins KTA38 & KTA50

📘 Practical Guide to the Operation & Maintenance of Cummins KTA38 & KTA50 Engines

- Dataplate reading and CPL usage

- Daily/weekly/monthly service intervals

- Coolant and oil maintenance

- Torque specs for critical bolts

- Marine-specific diagnostics

8. Cummins QSC 8.3 & QSL 9

📘 Practical Guide to Servicing Cummins QSC 8.3 & QSL 9 Engines

- Engine identification and CPL matching

- Cooling, fuel, and emissions system servicing

- DPF care and air intake inspection

- Error code basics and troubleshooting

- Best-practice startup and shutdown procedures

FAQs – Cummins Engine Service Essentials (25 Practical Questions)

- What’s the best way to identify my Cummins engine model?

Engine dataplate includes model, CPL, and serial number.

- What is a CPL number and why is it important?

It defines engine configuration for part compatibility.

- How often should I service a Cummins diesel engine?

Most require service every 250 to 1,000 hours.

- What are the most important service intervals?

Daily visual checks, 250-hour oil changes, and 1,000-hour major maintenance.

- Are service procedures different for marine vs. industrial engines?

Yes. Marine engines face unique challenges like saltwater corrosion.

- Can I perform maintenance without OEM tools?

Yes for basic service, but advanced repairs need OEM tools.

- Is it necessary to follow torque specs exactly?

Absolutely. Incorrect torque leads to failures.

- How do I avoid engine overheating?

Maintain coolant, clean heat exchangers, and check pumps.

- How can I tell if my injectors are failing?

Symptoms include smoke, misfiring, or fuel knock.

- What are signs of a failing turbocharger?

Whining sounds, oil leaks, and smoke.

- Should I flush the coolant system regularly?

Yes, especially in marine engines.

- How long do Cummins engines last?

Up to 25,000+ hours with good care.

- Can I mix coolants or oils?

No. Use Cummins-approved fluids only.

- How do I extend the life of my engine?

Follow service schedules and avoid overloading.

- Do all Cummins engines use aftercoolers?

Many do, especially turbocharged models.

- What causes engine failure most often?

Poor maintenance, overheating, and bad fuel.

- Can I diagnose faults without Cummins Insite?

Yes, but Insite provides advanced diagnostics.

- Are these guides relevant for Tier 3 or Tier 4 engines?

Yes, with emissions-system considerations.

- What can I service without removing the engine?

Oil, injectors, filters, sensors, and valves.

- Are Diesel Pro kits OEM?

No, but they meet or exceed OEM specs.

- Can I mix brands for sensors or filters?

Yes, if they meet compatibility requirements.

- How do I prevent marine engine corrosion?

Flush raw water systems and replace zincs.

- How should I prepare my engine for storage?

Change fluids, disconnect batteries, and fog cylinders if needed.

- Are rebuild kits universal?

No, they’re CPL-specific.

- Where can I get parts help?

Diesel Pro Power offers expert technical support.

Explore the individual service guides linked above for more in-depth, hands-on instructions tailored to your Cummins model.

© Diesel Pro Power

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588