Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engines are well known for their reliability, efficiency, and long service life. However, keeping these engines running at peak performance requires the right replacement parts when components wear out.

While OEM (Original Equipment Manufacturer) parts are commonly used, many high-quality aftermarket partsoffer equal or superior durability, better cost-effectiveness, and availability for rebuilding and maintaining Cummins B Series engines.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

This guide covers:

By selecting premium aftermarket parts, you can increase performance, reduce downtime, and save costs without compromising engine longevity.

High-Quality Aftermarket Parts vs. OEM Parts

When replacing components on Cummins B Series engines, many owners wonder whether to choose OEM or aftermarket parts. The truth is that not all aftermarket parts are the same—some are superior to OEM in quality and durability, while others may not meet Cummins’ high-performance standards.

1. Advantages of High-Quality Aftermarket Parts

2. When to Choose OEM Parts

OEM parts are typically engineered to exact factory specifications, ensuring consistent performance. However, they often come at a higher cost. Consider OEM parts if:

Choosing the Best Suppliers for Cummins Engine Components

Not all aftermarket parts suppliers provide the same quality and reliability. Choosing the right supplier is crucial for long-term durability and performance.

1. How to Identify a High-Quality Aftermarket Supplier

Commonly Replaced Parts and Their Impact on Performance

When maintaining or rebuilding a Cummins B Series engine, certain parts require regular replacement to ensure optimal performance, efficiency, and longevity. Below are the most commonly replaced components, along with their impact on engine reliability and performance.

1. Cylinder Head and Gaskets

- Warped cylinder heads from overheating.

- Blown head gaskets leading to compression loss.

- Cracked valve seats causing rough idling or misfires.

- High-strength cylinder heads with reinforced casting prevent cracking.

- MLS (Multi-Layer Steel) head gaskets provide superior sealing and prevent leaks.

- Aftermarket valve seats designed for extended durability.

Cylinder Head & Related Components for Cummins 6B Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BTA Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4B Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BTA Marine and Industrial Engines

2. Pistons, Rings, and Cylinder Liners

- Excessive oil consumption due to worn piston rings.

- Loss of compression and power from worn cylinder liners.

- Piston scoring or cracks from extreme heat.

- Ceramic-coated pistons resist high-temperature wear and reduce heat transfer.

- High-performance piston rings improve oil control and compression.

- Hardened cylinder liners extend engine life and prevent scoring.

Piston Kit & Related Components for Cummins 4B Marine and Industrial Engines

Piston Kit& Related Components for Cummins 4BT Marine and Industrial Engines

Piston Kit& Related Components for Cummins 4BTA Marine and Industrial Engines

Piston Kit& Related Components for Cummins 6B Marine and Industrial Engines

Piston Kit & Related Components for Cummins 6BT Marine and Industrial Engines

Piston Kit & Related Components for Cummins 6BTA Marine and Industrial Engines

3. Fuel System Components (Injectors, Fuel Pump, Lift Pump)

- Clogged injectors causing rough idle and misfires.

- Low fuel pressure leading to weak performance.

- Injection pump wear reducing fuel efficiency.

- Precision-machined injectors for cleaner combustion and better fuel economy.

- High-output fuel lift pumps to maintain proper pressure under heavy loads.

- Aftermarket high-flow injection pumps for increased horsepower.

Fuel Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Injector & Related Components for Cummins 4B Marine & Industrial Engines

Injector & Related Components for Cummins 4BT Marine & Industrial Engines

Injector & Related Components for Cummins 4BTA Marine & Industrial Engines

Injector & Related Components for Cummins 6B Marine & Industrial Engines

Injector & Related Components for Cummins 6BT Marine & Industrial Engines

Injector & Related Components for Cummins 6BTA Marine & Industrial Engines

4. Turbocharger and Air Intake System

- Turbo lag or failure due to worn bearings or oil starvation.

- Clogged intercoolers reducing boost pressure.

- Dirty air filters restricting airflow and increasing fuel consumption.

- Performance turbochargers with billet compressor wheels for faster spool times.

- High-flow intercoolers to improve cooling efficiency and power.

- High-performance air filters for better engine breathing.

Turbocharger & Related Components for Cummins 6BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 6BTA Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BTA Marine & Industrial Engines

5. Exhaust System and Emissions Control

- Clogged diesel particulate filters (DPF) causing excessive backpressure.

- Cracked exhaust manifolds reducing turbo efficiency.

- Leaky EGR valves leading to rough idling.

- High-flow exhaust manifolds improve turbo spool-up.

- Aftermarket DPF solutions for better exhaust flow and longevity.

- Performance EGR delete kits for off-road applications.

6. Cooling System Components (Radiator, Water Pump, Thermostat)

- Overheating due to clogged radiators or failing water pumps.

- Thermostat failures causing inconsistent temperature control.

- Coolant leaks from deteriorated hoses.

- Heavy-duty aluminum radiators for better heat dissipation.

- High-flow water pumps to improve coolant circulation.

- Low-temperature thermostats to maintain optimal engine temperature.

Fresh Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

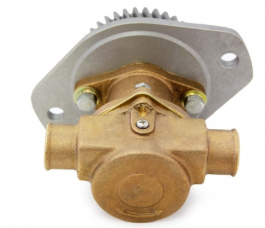

Marine Raw Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Final Thoughts

Selecting the right aftermarket parts for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engines is essential for maintaining peak performance, efficiency, and longevity. By choosing high-quality parts from reputable suppliers, you can:

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

Below are two videos of our customer Imperial Diesel Service, rebuilding a Cummins 6BT [ Part 1 & 2]

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588