Introduction: Why Maintenance Intervals Matter for the MG527

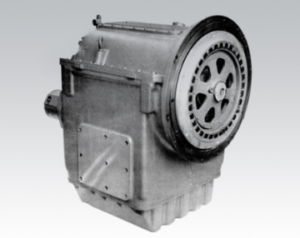

The Twin Disc MG527 Marine Gear is built to perform in some of the most demanding marine environments in the world. Whether installed on a workboat logging 2,000+ hours a year or on a recreational yacht cruising on weekends, the MG527 is only as reliable as the care it receives.

This marine gear is not a “set it and forget it” system. Just like any high-performance machinery, it relies on clean lubrication, tight tolerances, and routine monitoring to prevent wear. By establishing and following a structured maintenance checklist—daily and at regular service intervals—you reduce the risk of failures, ensure maximum performance, and significantly extend the service life of the gear.

This guide offers a detailed routine maintenance schedule based on best practices in the field, designed to keep your MG527 in top operating condition. Whether you’re a fleet manager, marine mechanic, or hands-on vessel owner, this maintenance checklist provides the foundation for safe and efficient operation.

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Daily and Pre-Trip Inspections For Twin Disc MG527 Marine Gears

Even if your vessel only operates a few hours per week, daily and pre-trip inspections are essential. These checks take less than 10 minutes and can prevent thousands of dollars in repair costs.

1. Oil Level Checks

Why It Matters:

The MG527 relies on pressurized lubrication to protect internal gears, bearings, and the clutch pack. Running even slightly low on oil can reduce pressure, increase internal friction, and accelerate wear.

Inspection Steps:

- Ensure the vessel is on level ground or water.

- Allow the engine and gear to cool if recently operated.

- Remove the dipstick or inspection plug from the transmission housing.

- Check that the fluid level is within the designated range.

- Look at fluid color: Clean oil should be light amber to reddish depending on the oil used.

- Dark, burnt-smelling, or milky fluid is a red flag (overheating or water intrusion).

Best Practice:

Top off only with approved marine transmission fluid compatible with the MG527 (more on oil types in the Scheduled Maintenance section). Overfilling is just as dangerous as underfilling.

2. Visual Inspection for Leaks

Why It Matters:

Oil leaks can indicate worn seals, cracked housings, or loose fittings. Even small leaks can result in dangerous oil loss over time.

Inspection Points:

- Check the base of the transmission near the output shaft for drips.

- Inspect the hydraulic clutch housing and surrounding area.

- Look around oil cooler lines, banjo bolts, and fittings.

- Examine the bell housing for signs of front seal failure (oil inside bell housing is a bad sign).

- Use a clean paper towel to wipe suspected areas to verify leak points.

Best Practice:

Clean the exterior of the gear periodically so that fresh leaks are easily visible. Consider using UV-reactive dye if a leak is suspected but hard to locate.

3. Shift Engagement and Operational Feel

Why It Matters:

Smooth, immediate gear engagement is a sign of a healthy hydraulic clutch and correct internal pressure. Delays, shuddering, or slipping during shifting signal impending failure.

Inspection Points:

- Engage forward and reverse before departure—feel for any delay.

- Listen for grinding, excessive clunking, or hesitation.

- Make sure the vessel responds instantly and smoothly.

- Test at idle and low-RPM throttle settings.

Warning Signs:

- Loud clunks may indicate worn coupling or excessive shaft play.

- Delayed engagement may point to low pressure or a worn clutch pack.

- Slipping under load is a critical problem—shut down and inspect immediately.

Scheduled Maintenance Intervals For Twin Disc MG527 Marine Gears

To keep your transmission reliable, schedule professional inspections and service at fixed engine-hour intervals. We recommend using 250, 500, and 1,000-hour milestones for general guidance. Adjust these intervals based on the vessel’s duty cycle, climate, and operating conditions.

250-Hour Maintenance Tasks

These tasks focus on basic fluid condition, filter checks, and bolt torque verification.

1. Oil Change Interval and Oil Type

Why It Matters:

After 250 hours of operation, even high-quality transmission oil begins to break down due to heat, oxidation, and particle contamination.

Recommended Oil:

- Use SAE 30 or SAE 40 heavy-duty engine oil approved for marine transmission use.

- Brands: Shell Rotella, Mobil Delvac, Chevron Delo—verify marine gear compatibility.

- Synthetic oils may be used in extreme climates or high-load applications.

Oil Change Steps:

- Warm engine slightly to thin oil.

- Use a vacuum oil extractor or drain plug (if accessible).

- Drain completely and inspect old oil for metallic debris or cloudy appearance.

- Refill to specified level using fresh, filtered oil.

Fluid Capacity Estimate:

Varies by model configuration, typically 2.5–5 gallons (9.5–19 liters).

2. Filter Inspection or Replacement

Internal Screens or External Filters:

- Some MG527 models include internal screen filters near the pump or a spin-on filter externally mounted on the cooling loop.

- Remove and inspect the screen for debris, sludge, or metallic shavings.

- Clean reusable screens with brake cleaner and reinstall.

- Replace disposable filters per manufacturer’s recommendation.

3. Bolt Torque Check

Over time, vibration and thermal cycling can loosen hardware. You should verify torque on:

- Bell housing bolts

- Output flange bolts

- Inspection covers

- Oil cooler line fittings

Use the correct torque values from the OEM manual, and always re-torque in a crisscross pattern.

4. Oil Cooler Function Check

- Inspect the raw water-cooled heat exchanger or closed-loop cooler for corrosion, blockages, or leaks.

- Ensure oil cooler hoses are not soft, cracked, or leaking at fittings.

- Flush with freshwater if the vessel has operated in dirty or salty conditions.

500-Hour Maintenance Tasks

This mid-level service interval is ideal for deeper inspection and partial disassembly tasks.

1. Full System Pressure Test

Use a hydraulic pressure gauge to check:

- Forward clutch pressure

- Reverse clutch pressure

- Pump output pressure

Compare results to specifications in the OEM manual. Deviation can indicate clutch wear, blocked passages, or pump degradation.

2. Clutch Pack Inspection (Visual or Partial Disassembly)

- Inspect friction plates through the inspection cover or by partial disassembly.

- Look for discoloration, scoring, or burn marks.

- Check that clutch springs or pressure plates are not warped.

Caution: Only disassemble if you are qualified or working under technician supervision. Internal pressure assemblies can be dangerous.

3. Shaft Seal Inspection

- Check the input and output shaft seals for weeping or signs of oil seepage.

- Look for dried oil tracks running from the seals—these are early indicators of wear.

4. Alignment Check

At 500 hours, verify that the engine-to-transmission and transmission-to-propeller shaft alignments are still within tolerance.

Use:

- Dial indicator kits

- Feeler gauges

- Laser alignment systems (if available)

Misalignment leads to accelerated wear and vibration issues.

5. EC300 System Check (if applicable)

If integrated with a Twin Disc EC300 electronic control system:

- Verify electronic shift response times.

- Use a diagnostic interface (if equipped) to check for error codes or lagging actuation.

- Update firmware/software as needed.

1,000-Hour Maintenance Tasks

This major service milestone involves deeper inspections and often includes rebuild planning for high-usage vessels.

1. Complete Oil and Filter Change

At this interval, even if interim oil changes have been performed, replace all fluid and filters.

- Consider switching to premium synthetic marine oil if operating in high-heat or high-torque conditions.

- Conduct an oil sample analysis to check for metal content, water intrusion, or oxidized additives.

2. Full Heat Exchanger Flush and Descale

- Remove the heat exchanger or open both ends.

- Use a marine-safe descaler (like Rydlyme or Barnacle Buster) to remove mineral and salt deposits.

- Backflush with freshwater until flow is clear and pressure is stable.

Overheated gears due to clogged coolers are one of the top preventable failure points.

3. Output Bearing Inspection

Remove the output coupling to inspect:

- Tapered roller bearing condition

- Raceway scoring or overheating

- Shaft end play and radial play

- Repack with marine-grade high-temp grease if applicable.

If wear is found, consider full bearing replacement.

4. Internal Clutch and Plate Inspection (Rebuild Planning)

At 1,000 hours, it may be time to:

- Remove the clutch housing

- Inspect friction discs, pressure plates, and clutch hubs

- Measure thickness of plates and compare to OEM tolerances

- Check for signs of slippage (bluing, smell, uneven wear)

If wear is excessive, order a rebuild kit from a trusted aftermarket provider like Diesel Pro Power, which includes seals, friction discs, gaskets, and bearings.

5. Mounting Bolt Retorque and Structural Check

- Recheck engine mounts, transmission feet, and frame connections.

- Look for cracks or flexing in the mounting bracket.

Optional: Seasonal or Lay-Up Maintenance

If your vessel is laid up for winter or inactive for a long period:

- Change oil before storage to remove acids.

- Run engine at idle to circulate oil.

- Fog transmission if recommended.

- Cover vent holes to prevent condensation.

- Check mounting hardware before recommissioning.

Checklist Summary: MG527 Routine Maintenance

| Interval | Maintenance Task |

| Daily / Pre-Trip | Oil level check, leak inspection, engagement feel |

| 250 Hours | Oil and filter change, torque check, cooler inspection |

| 500 Hours | Pressure test, clutch/shaft/seal check, alignment |

| 1,000 Hours | Complete oil service, full flush, clutch and bearing inspection, rebuild planning |

Final Thoughts: Protect Your Investment

The Twin Disc MG527 is one of the most respected marine gears in the industry—but no component, no matter how well-engineered, is immune to wear without maintenance.

By following the daily and scheduled checklists above, you can:

- Extend service life

- Improve vessel response

- Avoid costly repairs

- Maintain safe operation for crew and passengers

Stick to this guide, document your services, and work with trusted parts providers. With proper care, your MG527 can deliver thousands of reliable hours on the water.

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588