Introduction: Why Hydraulic Health Is Critical in the MG527

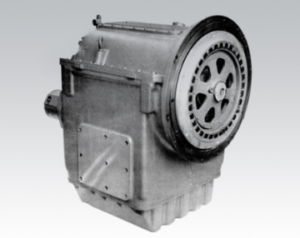

The Twin Disc MG527 Marine Gear is powered not just by mechanical gear sets and shafts—but by a precisely engineered hydraulic system. This system engages and releases the clutches, regulates pressure across the transmission, and ensures smooth forward and reverse shifting without the harshness of mechanical actuation.

Marine gears like the MG527 are designed for reliability under extreme load. But that reliability hinges on clean, stable hydraulic pressure. Any fault in this system—low pressure, sticky valves, worn clutch plates—can lead to delayed engagement, slippage under load, heat buildup, or complete transmission failure.

This section provides a deep dive into the hydraulic pressure system of the Twin Disc MG527, including how to test it, what the readings mean, and how to inspect and adjust the hydraulic clutch. This is one of the most important sections for marine technicians and operators who want to diagnose issues before they escalate.

Parts Catalog for Twin Disc MG527 Marine Transmissions

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Understanding the Hydraulic System in the MG527

Before diving into service, it’s crucial to understand how the hydraulic system works:

How It Works

- The hydraulic pump is mechanically driven by the input shaft. As soon as the engine is running, hydraulic pressure builds.

- Hydraulic fluid (transmission oil) flows through control valves to the clutch piston assemblies.

- The operator selects forward or reverse. The control valve directs pressurized fluid to the respective clutch pack, engaging the gear.

- When the operator returns the control to neutral, pressure is released, and the clutch disengages.

This system relies on correct pressure, clean oil, and tight tolerances. If any of these are off, the gear will respond poorly—or not at all.

Hydraulic Pressure Checks

Routine hydraulic pressure testing is one of the most overlooked yet essential diagnostics for MG527 service. It allows you to detect wear, leaks, or flow issues long before physical symptoms arise.

When to Test Hydraulic Pressure

- At every 500-hour service interval

- If experiencing delayed or sluggish gear engagement

- After rebuilding the clutch pack

- When replacing the hydraulic pump or valve body

- After an oil change, especially if the vessel has sat unused

What You Need

- Hydraulic pressure test gauge kit, rated to 0–300 PSI (or as per OEM spec)

- Banjo bolt adapter fittings (if required)

- Thread sealant or O-rings for leak-free installation

- OEM pressure test chart from the service manual for target values

- Stopwatch to monitor delay in pressure rise

Proper Test Points on the MG527

The MG527 has designated pressure ports, typically marked or threaded for 1/8″ or 1/4″ NPT hydraulic gauges. Locations include:

1. Forward Clutch Pressure Port

- Engaged only when forward gear is selected.

- Reading indicates pressure delivered to the forward clutch piston.

2. Reverse Clutch Pressure Port

- Pressurized only when reverse gear is selected.

- Confirms valve body is delivering correct signal.

3. Main Pump Pressure

- General system pressure at idle and throttle.

- Indicates health of pump, oil condition, and line integrity.

4. Lubrication Circuit Port (if equipped)

- Monitors oil flow to bearings and gears.

- Especially useful after cooler cleaning or oil line replacement.

Testing Procedure

- Warm Up the Transmission

Run engine at idle for 10–15 minutes. Shift into forward and reverse several times to circulate fluid.

- Shut Down and Attach Gauges

Carefully connect pressure gauges to the respective ports. Use correct adapters and tighten to prevent leaks.

- Restart Engine and Idle

Watch gauges rise with RPM. Document idle pressure.

- Record Pressures in All Three Gear Positions

- Neutral: No clutch pressure (but main system pressure should be present).

- Forward: Forward clutch port pressurizes.

- Reverse: Reverse clutch port pressurizes.

- Check at Operating RPM

Raise throttle to cruising RPM (approx. 1800–2000). Note how pressure responds.

- Shut Down and Remove Gauges

Reinstall plugs, clean fittings, and log all readings.

Acceptable Pressure Ranges (General Estimates)

Note: Always confirm exact pressure specs from OEM manual. The ranges below are common field targets:

| Test Point | Idle Pressure | Operating RPM Pressure |

| Main Pump | 80–120 PSI | 150–200 PSI |

| Forward Clutch | 100–130 PSI | 160–220 PSI |

| Reverse Clutch | 100–130 PSI | 160–220 PSI |

| Lube Port (if present) | 5–20 PSI | 10–30 PSI |

What the Numbers Mean

- Low Idle Pressure: Worn pump, clogged filter, air in lines, or low oil.

- Low Pressure at RPM: Valve body issues, internal leakage, or overheating fluid.

- No Pressure at Clutch Port: Valve not actuating, solenoid failure (if electric), or broken piston seal.

- Fluctuating Pressure: Air in system or cavitation.

- Slow Pressure Build-Up: Sludge in lines or failing pump vanes.

What to Do If Pressures Are Off

- Check oil level and condition first.

- Change filter and inspect for debris.

- Inspect valve body for sticking or scoring.

- If the pump is suspect, remove and test flow rate (requires bench testing tools).

- Rebuild valve body or clutch piston assemblies if leakage is suspected.

Hydraulic Clutch Inspection and Adjustment For Twin Disc MG527 Marine Gears

At the heart of gear engagement lies the clutch assembly. The MG527 uses hydraulic pressure to compress a pack of alternating friction and steel plates, delivering power to the output shaft.

Over time, these plates wear down, the pressure plates lose preload, and engagement becomes soft, delayed, or incomplete. Regular inspection can catch wear before catastrophic failure.

How the MG527 Clutch Works

- The clutch pack sits inside the transmission case, attached to the gear selector mechanism.

- When hydraulic pressure is applied, a piston or actuator pushes the clutch plates together.

- Friction is created, and the rotating force transfers from the input shaft to the output.

- Releasing pressure disengages the gear.

Signs of Clutch Wear or Failure

- Delayed Engagement

A delay between shift selection and movement means the clutch is not locking up fast enough.

- Slipping Under Load

The engine revs, but the boat doesn’t accelerate—indicates worn friction plates or low pressure.

- Gear Drops Out During Throttle

Internal wear or insufficient pressure causes disengagement.

- Shudder or Harsh Engagement

Could indicate uneven wear or warped plates.

- Burnt Smell from Transmission Oil

Overheating due to clutch friction wear. Oil may be dark or sludgy.

- Metal Flakes in Oil or Filter

Indicates plate breakdown or bearing contamination.

Accessing the Clutch for Inspection

Disclaimer: Refer to the OEM service manual for disassembly torque values, clutch dimensions, and procedures.

Basic Overview:

- Drain oil and remove access covers or bell housing (depending on vessel layout).

- Remove snap rings, spacers, or retaining plates.

- Slide out the clutch pack carefully.

Inspecting the Clutch Pack

Friction Plates

- Should have even wear across surface.

- Minimum thickness must be verified (see OEM spec).

- No glazing, scorching, or broken tabs.

Steel Plates

- Should be smooth and flat.

- Warping or heat discoloration means replacement.

Pressure Plate and Piston

- Check for cracks, scoring, or wear rings.

- Inspect seals and O-rings for deformation or leaks.

Measuring Clearance

- Use feeler gauges to measure stack height and clearance between pressure plate and retaining plate.

- Clearance that’s too high indicates wear; too low can cause drag or failure to disengage.

Adjusting or Replacing Components

- Replace any plates that are below minimum thickness.

- Always install plates in the original alternating order.

- Lubricate new plates with transmission fluid before assembly.

- Replace O-rings or piston seals during reassembly.

Hydraulic Clutch Reassembly Best Practices

- Use proper torque wrench settings for reassembly bolts.

- Always tighten in a cross-pattern to avoid distortion.

- Double-check plate alignment using guide studs or tools.

- Prime hydraulic system by shifting through gears several times after startup.

Re-Test After Service

After clutch service:

- Fill with new oil.

- Warm up and recheck pressures.

- Monitor shifting behavior.

- Run sea trial under various RPM and throttle conditions.

- Check for leaks and abnormal sounds.

Clutch Rebuild Kits and Parts Sourcing

If inspection reveals worn or damaged components, you’ll need:

- Clutch Rebuild Kit, including:

- Friction plates

- Steel plates

- O-rings

- Seals

- Snap rings

- Shims or spacers

Where to Buy:

Aftermarket kits from trusted suppliers like Diesel Pro Power provide high-quality replacements compatible with Twin Disc MG527 units—often at a lower cost and faster delivery than OEM.

Preventative Practices for Long-Term Hydraulic Health

- Change oil every 250 hours—old oil destroys hydraulic seals.

- Never operate the gear at low oil levels—air causes cavitation.

- Avoid prolonged idle in gear—creates heat without cooling flow.

- Use oil analysis every 500–1000 hours to detect early clutch wear.

- Replace hydraulic filters regularly.

- Check cooler flow monthly—blockage can overheat clutch fluid.

- Log pressure readings in your maintenance records for trend tracking.

Conclusion: Protecting the Most Critical System in Your MG527

The hydraulic system of the Twin Disc MG527 is what transforms operator input into real-world propulsion. Its performance is measured in milliseconds—how fast the gear shifts, how smoothly it engages, and how reliably it delivers torque.

Neglecting pressure checks or clutch inspections is like flying blind. But by following this detailed guide, you gain full control over the system that keeps your vessel maneuverable, safe, and responsive.

Regular pressure checks, clean oil, routine clutch inspections, and component replacements as needed will ensure your MG527 stays reliable for thousands of hours—delivering smooth shifts and high performance, trip after trip.

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588