May 9, 2025

1. Marine Applications of the Cummins 6.7L Engine

1. Recreational Yachts and Cruisers

2. Commercial Fishing Vessels

3. Passenger Ferries and Charter Boats

4. Pilot Boats and Patrol Craft

5. Tugboats and Support Vessels

2. Top Causes of Overheating in Marine Cummins 6.7L Engines

1. Restricted Raw Water Flow

2. Clogged or Fouled Heat Exchangers

3. Failing Thermostat

4. Low Coolant or Improper Coolant Mix

5. Raw Water Pump Failure

6. Clogged Keel Cooler (For Vessels Without Heat Exchangers)

7. Faulty Temperature Sensor or ECU Misreading

8. EGR Cooler Failure (in Emissions-Compliant Models)

9. Internal Corrosion from Improper Coolant or Storage

10. Overloading and Continuous High RPM Operation

3. Maintenance Best Practices for Marine Cummins 6.7L Engines

4. Recommended Parts from Diesel Pro Power

Conclusion: Keep Your QSB6.7 Cool and On the Water

Read More

April 28, 2025

Cummins 6CTA: Application Commercial Fishing Vessels

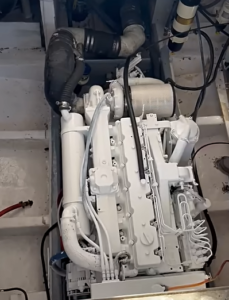

Introduction – Featuring Imperial Diesel Service, LLC Installation

Technical Overview of the Cummins 6CTA for Fishing Vessels

Why the Cummins 6CTA is a Top Choice for Commercial Fishing

Common Fisheries Using the Cummins 6CTA

Bottom Fishing in the Gulf of America (formerly known as the Gulf of Mexico) & Florida Keys

Lobster Fisheries – Maine, Canada, New England, and Florida Keys

Latin America and Caribbean Fisheries

Crab Fisheries – Alaska, Pacific Northwest, Gulf of America

Shrimp Trawling – Gulf of America, South America, Southeast Asia

Tuna Longlining – Pacific, Indian Ocean

Scallop and Clam Dredging – North Atlantic

Gillnetting and Trawling – Coastal and Nearshore

Installation Considerations for Commercial Fishing Vessels

Maintenance and Longevity in Fishing Applications

Aftermarket Support and CPL Cross-Reference

FAQs – Cummins 6CTA in Commercial Fishing

Final Thoughts

Read More

April 28, 2025

Torquing The Main Caps For A Cummins 6BT 210HP Video

Introduction

The Cummins 6BT 210 HP: An Engine Built for Work

Why Torquing the Main Caps Matters

The Torquing Process in Detail

Marine and Industrial Context

Why Diesel Pro Power Is the Trusted Source

From Video Preview to Complete Rebuild

Conclusion

Read More

April 28, 2025

️ Breakdown of What’s Shown in the Video:

17:51 Torquing The Main Cap Bearing Bolts

22:26 Installing The Gear Housing

25:17 Installing The Camshaft

39:32 Checking Piston Deck Height

Why a Cummins 6BT Might Need a Rebuild

1. High Operating Hours or Mileage

2. Oil Pressure Problems

3. Excessive Smoke or Blow-By

4. Cooling System Failures

5. Fuel System Wear

6. Preventive Maintenance for Long-Term Value

Parts Catalog For The Cummins 6BT

Buy Cummins 6BT Parts Online – Fast, Global & Accurate

Explore Our Extensive Cummins 6BT Inventory

Additional Cummins 6BT Parts We Offer

Why Buy Your Cummins 6BT Parts From Diesel Pro Power?

Over 40,000 Satisfied Customers Worldwide

Fast, Worldwide Shipping

Intuitive Online Ordering

Secure and Private

World-Class Customer Service

Read More

April 21, 2025

Overview of the Fuel Injection System For Cummins ISC, QSC8.3, ISL, QSL9

Introduction to High-Pressure Common Rail (HPCR) Technology

How Fuel Injection Works in These Engines

Fuel Injection Strategies

Troubleshooting Common Fuel System Issues For Cummins ISC, QSC8.3, ISL, QSL9

Symptoms of Fuel System Problems

Diagnostic Steps

Common Faults and Their Causes

Specific Troubleshooting Tips

Use of Diagnostic Software

Cleaning and Replacing Injectors For Cummins ISC, QSC8.3, ISL, QSL9

Injector Design and Function

When to Clean vs. When to Replace Injectors

Cleaning Procedures

External Cleaning

Ultrasonic Cleaning (Bench Cleaning)

On-Engine Injector Cleaner Kits

Replacement Procedure Overview

Tips for Successful Injector Replacement

Understanding the Injector Calibration Code

Preventing Future Injector Problems

Recommended Injector Service Intervals

Conclusion: Maintaining Optimal Fuel System Performance For Cummins ISC, QSC8.3, ISL, QSL9

Read More

April 14, 2025

The Legendary Bertram 31 and the Proven Cummins 6BT Pairing

Why Remove the Engines From a Bertram 31

Read More

Page 1 of 3812345...102030...»Last »

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588