Cummins 6BT Engine Parts - Crankshaft Section

Loading...

Loading... Crankshaft Components for Cummins 6BT Engines

The Cummins 6BT is a 5.9-liter inline-six powerhouse widely recognized for its durability in marine, industrial, agricultural, and heavy-duty applications. At the heart of its performance is the crankshaft assembly, a precision-engineered rotating component that converts linear piston movement into rotational force. The crankshaft and its related components—bearings, seals, gaskets, dampers, and plugs—play a critical role in ensuring smooth engine operation, minimizing vibration, and maintaining long-term reliability under high load conditions.

This section of our Cummins 6BT engine parts catalog focuses on crankshaft assemblies and the essential supporting components needed for professional rebuilds, preventative maintenance, and complete overhauls. All parts are engineered for exact fit, manufactured to OEM standards or higher, and backed by Diesel Pro Power’s reputation for serving over 40,000 satisfied customers worldwide.

Crankshaft Assemblies for Cummins 6BT

A new crankshaft for the Cummins 6B, 6BT, and 6BTA engine series is machined from high-strength forged steel for maximum fatigue resistance. Each unit comes pre-fitted with the front gear, ensuring easy installation and proper timing gear alignment. This ready-to-install design eliminates the need for transferring the gear from an old crankshaft, saving both time and labor.

Key Benefits:

-

Precision balancing to reduce engine vibration.

-

Hardened journals for extended bearing life.

-

Machined oil passages for optimal lubrication.

-

Direct fit for 6B, 6BT, and 6BTA applications.

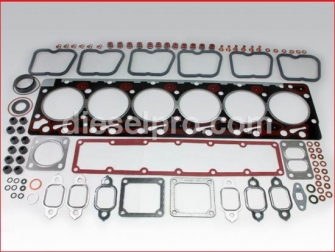

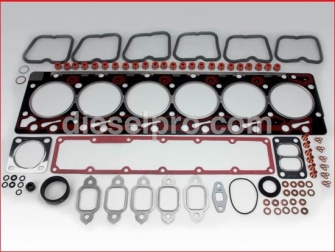

Gasket Sets for Crankshaft Installation

During a crankshaft replacement or bottom-end rebuild, proper sealing is essential. The Cummins 6BT crankshaft relies on both upper and lower gasket sets to prevent oil leaks, maintain compression, and ensure long-term dependability.

Lower Gasket Sets for Front Gear Train Engines

Designed for engines equipped with a front gear train, these gasket sets include seals and gaskets required for the lower end assembly. The materials are heat-resistant and oil-resistant to handle the extreme environment inside a diesel block.

Upper Gasket Sets for Standard and Oversize Applications

Upper gasket sets are available in both standard and oversize 0.25 mm variations. These kits are critical during top-end service when the cylinder head is removed, but they also provide sealing components that work in harmony with crankshaft installation to prevent oil seepage and coolant leaks.

Crankshaft Bearings (Shell Sets)

Proper bearing clearance is essential for crankshaft rotation and longevity. The Cummins 6BT crankshaft bearing sets—often referred to as shell sets—include both upper and lower shells for all main journals.

Standard Size Bearings

Ideal for engines where journal surfaces are still within OEM tolerance. They maintain correct oil clearance and support the crankshaft’s high-load operation.

Oversize Bearings (0.25 mm and 0.50 mm)

Used after crankshaft grinding or when wear requires increased bearing thickness. These bearings restore proper fit, prevent metal-to-metal contact, and extend service life. Oversize options ensure that even worn crankshafts can be salvaged through machining.

Crankshaft Seal Kits

Sealing the crankshaft where it exits the block is critical for preventing oil leaks. Our selection covers both the front and rear positions.

Front Crankshaft Seal Kits

Available in variations that include a dust shield or a sleeve, these seals are engineered to maintain oil retention under high RPM conditions. They also protect against dirt and debris intrusion, which can accelerate wear.

Rear Crankshaft Seal Kits

Designed for engines with a dry clutch housing, the rear seal kit includes a high-quality seal and sleeve for complete coverage. Proper installation prevents oil leaks that can damage clutches or cause slippage in marine transmissions.

Vibration Dampers

High-performance diesel engines like the Cummins 6BT generate torsional vibrations that can damage the crankshaft over time. Vibration dampers (also called harmonic balancers) absorb and control these oscillations, protecting the crankshaft and related components.

8.23" Outside Diameter Dampers

Designed with four bolt holes for secure mounting, these dampers are perfect for general-duty applications, balancing weight and damping efficiency.

9.7" Outside Diameter Dampers

The larger diameter offers increased vibration control, making them ideal for engines operating under sustained heavy loads or in high-performance marine applications.

Expansion Plug Kits for the Engine Block

Also known as freeze plugs or core plugs, expansion plugs prevent coolant leakage and protect the block from cracking in freezing conditions. Our Cummins 6BT expansion plug kits are storm-type for enhanced sealing, providing reliable long-term protection.

Benefits:

-

Corrosion-resistant construction for marine environments.

-

Complete kit for all block locations.

-

Designed for both 6BT and 6BTA variations.

Professional Installation and Maintenance Tips

-

Inspect Journal Surfaces: Before installing new bearings, ensure crankshaft journals are smooth and within OEM tolerances.

-

Use Correct Bearing Clearance: Incorrect clearance can lead to low oil pressure or bearing seizure.

-

Torque to Specifications: Follow Cummins torque values for main bearing caps, damper bolts, and seal housings.

-

Check Vibration Damper Condition: A worn damper can lead to premature crankshaft failure.

-

Replace Seals During Overhaul: Even if not leaking, old seals can harden and fail soon after reassembly.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588