Introduction

Servicing your Cummins 6C, 6CT, or 6CTA engine requires careful preparation, the right tools, and a solid understanding of the engine’s systems. These engines are known for their durability and reliability, but like all mechanical systems, they require regular maintenance and occasional repairs to ensure optimal performance. Whether you’re a professional mechanic, a fleet manager, or a hands-on operator, having the correct tools and following proper procedures will save time, prevent costly mistakes, and improve safety.

Parts Catalog for Cummins 6C Marine Engine

Parts Catalog for Cummins 6CT Marine Engine

Parts Catalog for Cummins 6CTA Marine Engine

This guide covers three essential areas:

- Necessary Tools for Maintenance and Repair

- Pre-Service Checks and Safety Considerations

- Common Issues Faced During Servicing

By the end of this guide, you’ll have a comprehensive understanding of how to prepare for servicing your Cummins C Series engine, ensuring efficiency, safety, and engine longevity.

1. Necessary Tools for Maintenance and Repair

When it comes to maintaining and repairing Cummins 6C, 6CT, and 6CTA engines, having the right tools is crucial. While basic hand tools are a must, specialized equipment is often required for specific tasks like adjusting valve lash, replacing injectors, or diagnosing electronic systems.

A. Basic Hand Tools

These tools form the foundation of any diesel engine maintenance kit:

1. Socket Set

- Metric and SAE sockets (ranging from 8mm to 32mm) for different bolt sizes.

- Deep sockets for hard-to-reach fasteners.

- Impact sockets for heavy-duty work, especially on rusted or high-torque bolts.

2. Wrenches

- Combination wrenches (open-end and box-end) for general use.

- Adjustable wrenches for odd-sized fittings.

- Torque wrenches (both foot-pound and inch-pound ranges) for ensuring bolts are tightened to manufacturer specifications.

3. Screwdrivers

- Flathead and Phillips screwdrivers in various sizes for hose clamps, covers, and small components.

- Pliers and Cutters:

- Needle-nose pliers for tight spaces.

- Locking pliers (Vise-Grips) for stubborn parts.

- Wire cutters and strippers for electrical work.

4. Hammers

- Dead blow hammer for controlled force without damaging parts.

- Ball-peen hammer for light metalwork.

- Pry Bars:

- Useful for loosening stubborn components or aligning parts during assembly.

B. Specialized Tools for Cummins Engines

Cummins engines require specific tools designed for diesel components, which often operate under higher pressures and tolerances than gasoline engines.

- Valve Adjustment Tools

- Feeler gauges for measuring valve lash clearances.

- Valve adjustment wrench (specific to Cummins engines) for precise adjustments.

2. Injector Puller Tool

- Required to safely remove fuel injectors without damaging the cylinder head.

3. Fuel System Tools

- Fuel pressure gauge to diagnose fuel delivery issues.

- Fuel line wrenches (flare nut wrenches) for high-pressure lines.

4. Compression Tester

- A diesel compression tester is necessary to evaluate engine health and diagnose issues related to low compression.

5. Timing Tools

- Timing pin and gear alignment tools for setting accurate timing during major repairs.

6. Belt Tension Gauge

- Ensures correct tension on serpentine and accessory belts to prevent slippage or premature wear.

7. Cooling System Tools

- Coolant pressure tester to identify leaks in the radiator, hoses, or head gasket.

- Thermometer or infrared gun to monitor coolant temperatures during diagnostics.

8. Electronic Diagnostic Tools

- Cummins INSITE software for ECM diagnostics, fault code reading, and performance monitoring.

- OBD-II or J1939 diagnostic scanners for electronically controlled engines.

C. Fluids, Lubricants, and Consumables

Keeping a stock of essential consumables will streamline maintenance tasks:

- Engine oil (SAE 15W-40) meeting API CI-4 or higher standards.

- Coolant/antifreeze with proper corrosion inhibitors.

- Diesel fuel additives (anti-gel, injector cleaner).

- Brake cleaner or degreaser for cleaning parts.

- Thread sealant and anti-seize compound for fastener protection.

- Rags, shop towels, and gloves for clean, safe working conditions.

2. Pre-Service Checks and Safety Considerations

Before starting any maintenance or repair work on your Cummins 6C, 6CT, or 6CTA engine, it’s essential to perform pre-service checks and follow safety protocols. Diesel engines operate under high pressures, temperatures, and voltages, making safety a top priority.

A. Pre-Service Checks

- Visual Inspection:

- Check for oil leaks, coolant leaks, or signs of fuel seepage.

- Inspect belts, hoses, and wiring for wear, cracks, or damage.

2. Fluid Levels:

- Verify engine oil, coolant, transmission fluid, and hydraulic fluid levels.

- Check for signs of contamination, such as coolant in the oil (milky appearance) or fuel in the oil (diesel smell).

3. Battery Condition:

- Ensure the battery is fully charged and terminals are clean and tight.

- Disconnect the battery when working on electrical components to prevent accidental shorts.

4. Diagnostic Scan:

- For electronically controlled engines, perform a diagnostic scan to identify any stored fault codes that may point to issues requiring attention.

5. Review Service History:

- Check maintenance logs for overdue services or recurring issues.

B. Safety Considerations

- Personal Protective Equipment (PPE)

- Safety glasses to protect against debris and fluid splashes.

- Gloves for handling hot, sharp, or oily components.

- Steel-toe boots to protect feet from heavy falling objects.

2. Engine Cool-Down

- Allow the engine to cool before working on the cooling system, turbocharger, or exhaust components to prevent burns.

3. Fuel System Safety

- Relieve pressure in the fuel system before disconnecting lines to prevent high-pressure diesel spray, which can penetrate the skin and cause serious injury.

4. High-Pressure Systems

- Never loosen high-pressure fuel lines while the engine is running.

- Use proper diesel-rated tools designed to handle high-pressure fittings.

5. Lockout/Tagout (LOTO)

- For industrial equipment, follow lockout/tagout procedures to ensure the engine cannot be started accidentally during maintenance.

6. Proper Ventilation

- Work in a well-ventilated area when running the engine to avoid exposure to carbon monoxide from exhaust fumes.

3. Common Issues Faced During Servicing

Even with proper preparation, servicing diesel engines like the Cummins C Series can present challenges. Recognizing these common issues will help you troubleshoot more effectively and avoid costly mistakes.

A. Fuel System Problems

- Air in the Fuel System:

- Symptoms: Hard starting, rough idle, loss of power.

- Cause: Air can enter the fuel system during filter changes or from loose fittings.

- Solution: Bleed the fuel system using the manual primer pump and bleed screws until fuel flows without air bubbles.

2.Injector Issues

- Symptoms: White smoke, misfires, poor fuel economy.

- Cause: Clogged or leaking injectors due to fuel contamination.

- Solution: Remove and inspect injectors, replace if faulty, and ensure fuel filters are regularly maintained.

3. Fuel Contamination

- Symptoms: Stalling, sluggish performance, injector damage.

- Cause: Water, dirt, or microbial growth in the fuel tank.

- Solution: Drain the contaminated fuel, replace filters, and clean the fuel system.

Fuel System & Related Components for Cummins 6C Marine & Industrial Engines

Fuel System & Related Components for Cummins 6CT Marine & Industrial Engines

Fuel System & Related Components for Cummins 6CTA Marine & Industrial Engines

B. Cooling System Challenges

- Overheating

- Symptoms: High temperature readings, coolant loss, steam from the radiator.

- Cause: Low coolant levels, clogged radiator, faulty thermostat, or water pump failure.

- Solution: Check coolant levels, inspect the radiator for blockages, and test the thermostat using a hot water bath.

2. Coolant Leaks

- Symptoms: Puddles under the engine, low coolant warning lights.

- Cause: Leaking hoses, radiator cracks, or worn gaskets.

- Solution: Perform a cooling system pressure test to identify leaks and replace faulty components.

Fresh Water Pump & Related Components for Cummins 6C Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6CT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6CTA Marine & Industrial Engines

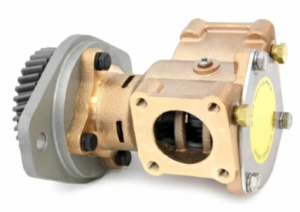

Raw Water Pump & Related Components for Cummins 6C Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6CT Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6CTA Marine & Industrial Engines

C. Lubrication System Issues

- Low Oil Pressure

- Symptoms: Warning lights, engine knocking, excessive wear.

- Cause: Low oil level, clogged oil filter, worn oil pump, or internal bearing wear.

- Solution: Check oil levels, replace the oil filter, and inspect the oil pump for wear.

2. Oil Leaks

- Symptoms: Oil spots under the vehicle, burning oil smell.

- Cause: Worn gaskets, loose drain plugs, or cracked seals.

- Solution: Identify the source of the leak, replace gaskets or seals as needed, and ensure proper torque on fasteners.

Lubrication System & Related Components for Cummins 6C Marine & Industrial Engines

Lubrication System & Related Components for Cummins 6CT Marine & Industrial Engines

Lubrication System & Related Components for Cummins 6CTA Marine & Industrial Engines

D. Electrical System Troubles

- Starting Issues

- Symptoms: Clicking sounds, slow cranking, or no response when turning the key.

- Cause: Weak battery, corroded terminals, faulty starter motor, or bad ground connection.

- Solution: Check battery voltage, clean terminals, and perform a voltage drop test on the starter circuit.

2. Charging System Failures

- Symptoms: Battery not charging, dimming lights, dashboard warning indicators.

- Cause: Faulty alternator, bad voltage regulator, broken belts, or wiring issues.

- Solution: Test the alternator output with a multimeter and inspect the charging system wiring.

Electrical System & Related Components for Cummins 6C Marine & Industrial Engines

Electrical System & Related Components for Cummins 6CT Marine & Industrial Engines

Electrical System & Related Components for Cummins 6CTA Marine & Industrial Engines

E. Exhaust and Emissions Problems

- Excessive Smoke

- Black Smoke: Caused by over-fueling, clogged air filters, or turbocharger issues.

- White Smoke: Indicates unburned fuel due to injector problems or low compression.

- Blue Smoke: Signifies burning oil from worn piston rings or valve seals.

2. DPF (Diesel Particulate Filter) Blockages

- Symptoms: Loss of power, poor fuel economy, and increased regeneration cycles.

- Cause: Soot accumulation due to incomplete combustion or lack of proper regeneration.

- Solution: Perform a forced DPF regeneration using diagnostic tools or replace the filter if necessary.

Exhaust & Related Components for Cummins 6C Marine & Industrial Engines

Exhaust & Related Components for Cummins 6CT Marine & Industrial Engines

Exhaust & Related Components for Cummins 6CTA Marine & Industrial Engines

Conclusion

Servicing your Cummins 6C, 6CT, or 6CTA engine effectively requires the right tools, careful preparation, and a strong focus on safety. By conducting thorough pre-service checks, using the proper equipment, and being aware of common issues, you can maintain your engine’s performance and reliability for years to come.

Regular maintenance doesn’t just keep your engine running smoothly—it prevents costly breakdowns, improves fuel efficiency, and extends the lifespan of critical components. Whether you’re performing routine oil changes, adjusting valve lash, or diagnosing complex electronic issues, having a well-organized approach ensures successful servicing every time.

Parts Catalog for Cummins 6C Marine Engine

Parts Catalog for Cummins 6CT Marine Engine

Parts Catalog for Cummins 6CTA Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588