Cummins 6CT Engine Parts -

Fuel Section

Loading...

-

3966154

Pump Style Mechanical Lever

Price: $ 101.81

-

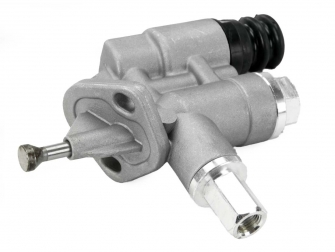

3918076

Pump Style Mechanical Piston, Used with rotary pumps

Price: $ 64.68

-

3936319

Pump Style Mechanical Piston, Used with non-rotary pumps

Price: $ 101.38

-

3939258

Two per fuel pump

Price: $ 2.14

-

3890017

3.7" diameter, 5.46" height, thread: + 13/16- 18" - 14 UNF-28

Price: $ 32.59

-

4990879

2.813" diameter, 4.57" height, thread: M16 x 1.5" - 6

Price: $ 29.02

-

3959612

3.68" diameter, 6.92" height, thread: + 7/8" - 14 UNF-28

Price: $ 39.51

-

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INT

Price: $ 44.78

-

3906783K

For cylinders 1, 2 and 3

Truck & Industrial application

Price: $ 213.13

-

3906787K

For cylinders 4, 5 and 6

Truck & Industrial application

Price: $ 261.22

-

3921978

For the fuel pump shut-off

Price: $ 278.46

-

3921980

For the fuel pump shut-off

Price: $ 286.42

-

4019329

Hose for fuel cooler water inlet connection

Price: $ 88.88

-

3866019

Hose for fuel cooler water outlet connection

Price: $ 58.62

-

190

3-7/16" to 3-3/4"

Price: $ 14.50

-

500

Filter element 2010 included

Price: $ 268.75

-

900

Filter element 2040 included

Price: $ 362.64

-

1000

Filter element 2020 included

Price: $ 449.65

-

-

-

-

-

-

-

3957921

Brass plug NPT 3/8”, zinc length 1”

Price: $ 20.77

-

23520023

5 PSI make/break with 1/8 npt

Price: $ 95.81

-

23520024

10 PSI make/break with 1/8 npt

Price: $ 99.79

-

23520025

20 PSI make, break with 1/8 npt

Price: $ 96.44

-

23511819

27 PSI make/break with 1/8 npt

Price: $ 81.10

-

Loading...

Loading...

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588