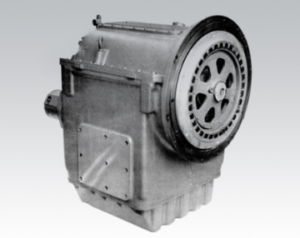

Servicing a marine transmission like the Twin Disc MG527 requires more than just experience and technical knowledge—it requires the right tools, the proper safety precautions, and a disciplined, organized approach to every maintenance or repair task.

The MG527 is a robust and highly engineered transmission, but its reliability depends on being serviced with precision. Whether you’re conducting routine maintenance, replacing seals, checking alignment, or rebuilding components, you need specific tools and safety protocols to protect both your equipment and yourself.

This section offers an exhaustive breakdown of everything you’ll need to work on the MG527—including common hand tools, specialty instruments, and vital safety gear. This guide is essential for fleet mechanics, mobile marine service providers, and hands-on vessel owners who want to reduce costly shop visits and maximize operational uptime.

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Required Tools for Servicing the Twin Disc MG527

The tools required for proper MG527 maintenance range from basic hand tools to specialized marine alignment systems and fluid testing kits. Below is a categorized breakdown of the essentials.

1. Basic Hand Tools

Even with the most advanced diagnostics and electronic controls, the heart of marine service remains in manual tools. Here’s what you’ll need in your toolbox at a minimum:

- Socket Set (Metric and SAE):

For removing and torquing fasteners across all access panels and covers. Deep sockets are often necessary for hard-to-reach bolts.

- Combination Wrenches (Metric and SAE):

Essential for hydraulic line fittings, inspection covers, and component mounts.

- Hex and Torx Key Sets:

Used for removing small access plates or sensor mounting bolts. Many marine gears include hex plugs for fluid inspection and drainage.

- Screwdrivers (Flathead and Phillips):

Used for everything from loosening hose clamps to removing electrical connectors.

- Pliers (Needle-Nose, Channel Lock, Locking):

For managing hydraulic lines, snap rings, and small hardware in tight spaces.

- Rubber Mallet and Dead Blow Hammer:

Useful for tapping housings or covers without damaging aluminum or composite materials.

- Pick Set and Seal Pullers:

Removing stubborn O-rings and oil seals is impossible without the right finesse tools.

- Pry Bars:

For carefully separating mating surfaces without damaging gasket faces.

- Hose Clamp Tools:

Specialty tools to quickly remove or tighten cooling or oil hose clamps.

- Utility Knife and Gasket Scraper:

A must for cleaning old gasket material during resealing procedures.

These tools may seem basic, but improper use or poorly maintained tools can result in stripped fasteners, gouged sealing surfaces, or broken components—so keep them clean, sharp, and calibrated.

2. Torque Wrenches

Proper torque application is essential when working with the MG527. Over-torquing can crack housings or crush gaskets. Under-torquing can cause leaks, vibration, and premature wear.

Here’s what you need:

- 1/4″, 3/8″, and 1/2″ Drive Torque Wrenches:

Cover a full range of torque specs, from delicate fasteners on sensors and valve bodies to the main mounting bolts.

- Torque Range Coverage:

- 1/4″ Drive: 20–200 in-lbs (2.3–22.6 Nm)

- 3/8″ Drive: 10–100 ft-lbs (13.5–135.6 Nm)

- 1/2″ Drive: 30–250 ft-lbs (40.7–339 Nm)

- Calibrated Annually:

Torque wrenches should be professionally calibrated at least once per year or after any impact.

- Use in Both Directions:

For bolts that may be torqued in reverse direction (though most MG527 fasteners are standard-thread).

Proper torque is particularly critical when reinstalling oil pan bolts, housing covers, bearing retainers, and couplings—especially where thread sealant is used.

3. Alignment Tools

One of the most critical aspects of any marine transmission installation is ensuring proper engine-to-gear alignment. Misalignment can cause catastrophic damage to the input shaft, output bearings, and coupling components.

Essential Alignment Tools Include:

- Dial Indicator Kit with Magnetic Base:

Used to verify misalignment between engine and transmission flanges. Both radial and angular misalignment should be within manufacturer tolerance (often ±0.003”).

- Straight Edge and Feeler Gauges:

Good for quick checks and initial alignment procedures.

- Flexible Shaft Coupling Tool:

Measures shaft deflection and ensures coupling alignment between gearbox and propeller shaft.

- Laser Alignment Systems (Advanced):

Offers fast, high-precision alignment with visual displays. Particularly helpful in vessels with dual engines or hard-to-reach spaces.

Alignment should always be checked after:

- Installing a new engine or gear

- Major hull repairs or modifications

- Hard groundings or heavy vibration events

Ignoring alignment can lead to premature bearing failure, seal leaks, and gear vibration.

4. Specialty Tools (If Applicable)

While many MG527 service tasks can be handled with common tools, certain repairs or rebuilds require job-specific tools. These may be needed for:

Hydraulic System Service

- Hydraulic Pressure Gauge Kit:

For testing forward and reverse clutch pressures at service ports. Twin Disc often specifies minimum pressure ranges that must be met for proper engagement.

- Banjo Bolt Adapters:

Required for connecting pressure test kits to OEM hydraulic ports.

- Manual Shift Test Tool:

Used to manually engage the forward or reverse clutch pack when troubleshooting electrical shift issues.

Seal and Bearing Installation Tools

- Bearing Puller Set and Slide Hammer:

For safely extracting worn bearings from shafts or housings.

- Seal Driver Kit:

Ensures new shaft seals are seated correctly without distortion or damage.

- Clutch Spring Compressor Tool:

Some clutch pack designs require internal compression to remove and replace friction and steel plates.

Oil and Cooling System Tools

- Vacuum Oil Extractor Pump:

Speeds up oil changes and minimizes spills. Useful in tight engine rooms where drain pans won’t fit.

- Fluid Transfer Pump:

Ideal for refilling the transmission through side ports without creating air pockets.

- Infrared Thermometer or Digital Temp Probe:

Monitors oil temperature during sea trials or in troubleshooting scenarios.

Diagnostic and Digital Tools

- Multimeter (True RMS):

For testing sensor continuity, solenoid operation, or control voltage.

- OBD or EC300 Interface Tool (Optional):

If integrated with Twin Disc EC300 controls, this diagnostic interface may be used to monitor shift timing, response delays, or fault codes.

Personal Protective Equipment (PPE)

Working on a marine transmission involves exposure to pressurized oil systems, rotating machinery, and tight compartments. PPE is not just a precaution—it’s a non-negotiable requirement for safe service.

1. Gloves

- Nitrile Gloves:

Best for oil changes, seal replacement, or light-duty work involving oil contact.

- Mechanic’s Gloves (Kevlar-lined):

Essential when handling heavy parts like the output shaft or removing tight hydraulic fittings. They provide cut protection and grip.

- Chemical-Resistant Gloves:

Used when working with cleaning agents, brake cleaner, or degreasers during surface preparation.

2. Safety Goggles

- ANSI Z87.1 Rated Goggles or Glasses:

Eye protection is required when draining fluids, using power tools, or working under a vessel’s transmission.

- Anti-Fog Coated:

Critical in high-humidity engine rooms to maintain visibility.

- Side Protection:

Shields against high-pressure spray from hydraulic lines or compressed air tools.

3. Steel-Toed Boots

- Oil-Resistant Soles:

Prevent slipping in engine room conditions.

- Reinforced Toes:

Essential when working with heavy housings, couplings, or shafts that could be dropped.

- Waterproofing:

Beneficial in bilge or wet environments typical in marine settings.

4. Oil-Resistant Clothing

- Mechanic Coveralls or Bibs:

Protect your skin and daily clothes from oil, coolant, or debris. Prefer dark-colored, fire-retardant materials.

- Knee Pads:

Many engine room service tasks require kneeling or crawling—knee protection helps reduce strain.

5. Fire Extinguisher Nearby

- Marine-Grade Fire Extinguisher:

Always have an accessible fire extinguisher within arm’s reach when working with:- Hot engines

- Hydraulic lines

- Flammable fluids

- Electrical tools

- Type B-C or A-B-C Rated:

For engine rooms, always use multi-class extinguishers rated for fuel, oil, and electrical fires.

- Routine Inspection:

Ensure your extinguisher is charged and within service date.

Optional but Recommended Shop Equipment

For those with dedicated marine service shops or outfitted maintenance spaces, these tools can elevate your MG527 work to a professional level:

- Workbenches with Vise:

Provides a stable platform for disassembling or pressing components.

- Parts Washer or Solvent Tank:

Crucial for cleaning reused parts and removing sludge buildup.

- Compressed Air System:

For blowing out hydraulic lines or drying parts after degreasing.

- Drip Trays and Absorbent Mats:

Maintain a clean workspace and prevent oil runoff into bilges or dockside.

- Transmission Jack or Hoist:

MG527 units are heavy. If you’re removing the gear from the vessel, you’ll need proper lifting equipment.

Pre-Service Setup and Safety Protocols

Before you begin any service on the MG527, you should:

- Shut Down Engine and Cool Down Completely

Never work on a transmission while the engine is hot or running. Wait at least 30–45 minutes after shut-down.

- Isolate Power Sources

Disconnect the battery and shut down hydraulic pumps if applicable.

- Tagout/Lockout System

Use clear labels and physical locks on any controls or power circuits to prevent accidental engagement.

- Ventilate the Area

Ensure there is proper ventilation in enclosed engine rooms to avoid fume accumulation from solvents or oil.

- Lighting

Use explosion-proof or sealed LED lights if you’re working in confined or potentially flammable environments.

- Buddy System

If working dockside or in a shipyard, always have a second person present in case of injury or emergency.

Maintenance Logbook and Documentation Tools

Proper documentation is an often-overlooked “tool.” You should track every inspection, service, torque application, and fluid change with:

- Digital Maintenance Logbook or Paper Binder

- Torque Sheet with Date and Values Applied

- Photo Documentation (Before and After Repairs)

- Oil Sample Records

- Alignment Logs

Not only does this protect the vessel owner and technician—it builds a history of care that can boost resale value or justify warranty claims.

Conclusion: Set Yourself Up for Success

Servicing the Twin Disc MG527 isn’t about improvising—it’s about executing a clear, methodical plan using the right tools and prioritizing safety. With the proper torque equipment, diagnostic tools, hydraulic test kits, and personal safety gear, you can conduct inspections, repairs, and rebuilds with confidence.

Failure to use correct tools or skip safety steps leads to damaged components, poor performance, and risk of injury. In contrast, a technician equipped with knowledge and the right gear ensures that the MG527 operates at peak reliability—hour after hour, mile after mile.

Plate Kit For Twin Disc MG527 Marine Transmissions

Rebuilt Gears for Twin Disc MG527 Marine Transmissions

Gasket Kits For Twin Disc MG527 Marine Transmissions

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588