Cummins B Series engines are among the most reliable and widely used diesel engines in the world. Known for their mechanical simplicity, high torque output, and long lifespan, these engines have been the backbone of marine, construction, trucking, agricultural, and industrial applications for decades. Their ease of maintenance, availability of aftermarket parts, and adaptability make them a preferred choice for heavy-duty operations worldwide.

Parts Catalog for Cummins 4B Marine & Industrial Engines

Parts Catalog for Cummins 4BT Marine & Industrial Engines

Parts Catalog for Cummins 4BTA Marine & Industrial Engines

Parts Catalog for Cummins 6B Marine & Industrial Engines

Parts Catalog for Cummins 6BT Marine & Industrial Engines

Parts Catalog for Cummins 6BTA Marine & Industrial Engines

This section provides a detailed breakdown of the Cummins B Series family, covering:

- The differences between the 6B, 6BT, and 6BTA engines.

- The differences between the 4B, 4BT, and 4BTA engines.

- The key components of these engines and their functions.

- The reasons why they are widely used across multiple industries.

By understanding these engines in depth, owners and mechanics can maximize their performance, longevity, and reliability through proper maintenance and servicing.

Overview of the Cummins B Series Family

The Cummins B Series consists of four-cylinder and six-cylinder configurations, both designed for heavy-duty diesel applications. The B Series gained immense popularity because of its mechanical fuel system, which provides excellent durability and is less dependent on electronic controls than modern diesel engines.

The most common models include:

- 6B (Naturally Aspirated) – No turbocharger, ideal for low-power applications.

- 6BT (Turbocharged) – Increased horsepower and efficiency with a turbocharger.

- 6BTA (Turbocharged and Aftercooled) – Turbocharged and equipped with an aftercooler for enhanced performance.

- 4B (Naturally Aspirated) – A compact, four-cylinder version of the 6B.

- 4BT (Turbocharged) – Turbocharged four-cylinder for better power and efficiency.

- 4BTA (Turbocharged and Aftercooled) – The highest-performing four-cylinder B Series variant.

The B Series shares a common architecture, including a parent bore block, high-strength components, and modular design, making them versatile and highly serviceable.

Differences Between 6B, 6BT, and 6BTA Engines

The six-cylinder B Series engines are the most commonly used Cummins engines in trucking, marine, and industrialapplications. While they share the same basic design, each variant offers different performance characteristics.

Cummins 6B (Naturally Aspirated)

The Cummins 6B is the simplest version of the B Series family. It is naturally aspirated—meaning it lacks a turbocharger—and relies solely on atmospheric air pressure for combustion.

Key Features of the 6B:

Advantages:

- Simple design with fewer components that can fail.

- Easier maintenance due to no turbocharger or aftercooler.

- Ideal for low-power applications where longevity is more important than speed.

Disadvantages:

- Lower power output compared to turbocharged versions.

- Less fuel efficiency under heavy loads.

Parts Catalog for Cummins 6B Marine & Industrial Engines

Cummins 6BT (Turbocharged)

The 6BT is the turbocharged version of the 6B, offering significantly more power and torque. The turbocharger allows for better fuel combustion, increasing performance and efficiency.

Key Features of the 6BT:

Advantages:

- Increased power and torque with the addition of a turbo.

- More efficient fuel use, reducing operational costs.

- Greater adaptability in commercial and industrial applications.

Disadvantages:

- Higher temperatures due to increased combustion pressure.

- Requires better cooling system maintenance to prevent overheating.

Parts Catalog for Cummins 6BT Marine & Industrial Engines

Cummins 6BTA (Turbocharged and Aftercooled)

The 6BTA is the most advanced version of the six-cylinder B Series, incorporating both a turbocharger and an aftercooler to optimize air intake temperature and combustion efficiency.

Key Features of the 6BTA:

Advantages:

- Highest horsepower output among the 6B models.

- Improved efficiency due to cooler intake air.

- Better reliability in high-performance and marine applications.

Disadvantages:

- More complex cooling system, requiring an aftercooler and additional maintenance.

- Higher risk of overheating if cooling components fail.

Parts Catalog for Cummins 6BTA Marine & Industrial Engines

Differences Between 4B, 4BT, and 4BTA Engines

The four-cylinder versions of the Cummins B Series are designed for compact applications where space and weight are concerns. These engines are particularly popular in industrial equipment, small trucks, and off-road machinery.

Cummins 4B (Naturally Aspirated)

- Displacement: 3.9L (239 cubic inches)

- Power Output: 60-100 HP

- No turbocharger, making it ideal for low-power applications.

Parts Catalog for Cummins 4B Marine & Industrial Engines

Cummins 4BT (Turbocharged)

- Displacement: 3.9L (239 cubic inches)

- Power Output: 105-150 HP

- Turbocharged for better fuel efficiency and performance.

Parts Catalog for Cummins 4BT Marine & Industrial Engines

Cummins 4BTA (Turbocharged and Aftercooled)

- Displacement: 3.9L (239 cubic inches)

- Power Output: 150-180 HP

- Turbocharged and aftercooled for maximum efficiency.

The 4BTA is commonly used in military, marine, and industrial equipment where compact power is needed.

Parts Catalog for Cummins 4BTA Marine & Industrial Engines

Key Components and Their Functions

1. Fuel System

- Fuel injectors deliver diesel into the combustion chamber.

- Fuel pumps regulate fuel pressure and flow.

Fuel Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Injector & Related Components for Cummins 4B Marine & Industrial Engines

Injector & Related Components for Cummins 4BT Marine & Industrial Engines

Injector & Related Components for Cummins 4BTA Marine & Industrial Engines

Injector & Related Components for Cummins 6B Marine & Industrial Engines

Injector & Related Components for Cummins 6BT Marine & Industrial Engines

Injector & Related Components for Cummins 6BTA Marine & Industrial Engines

2. Turbocharger and Aftercooler (6BT, 6BTA, 4BT, 4BTA)

- Turbocharger: Increases power by compressing intake air.

- Aftercooler: Cools compressed air for better combustion.

Turbocharger & Related Components for Cummins 6BT Marine & Industrial EnginesTurbocharger & Related Components for Cummins 6BTA Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BT Marine & Industrial Engines

Turbocharger & Related Components for Cummins 4BTA Marine & Industrial Engines

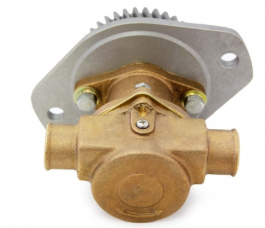

3. Cooling System

- Water pump and radiator maintain engine temperature.

- Raw water pump (marine applications) pulls seawater for cooling.

Fresh Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Marine Water Pump for Cummins 6B Series Marine Engines

Marine Raw Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

4. Lubrication System

- Oil pump distributes oil to reduce friction and wear.

Oil Pump & Related Components for Cummins 4B Marine and Industrial Engines

Oil Pump & Related Components for Cummins 4BT Marine and Industrial Engines

Oil Pump & Related Components for Cummins 4BTA Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6B Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6BT Marine and Industrial Engines

Oil Pump & Related Components for Cummins 6BTA Marine and Industrial Engines

5. Cylinder Head and Valvetrain

- Valves control intake and exhaust gases.

- Pushrods and rocker arms regulate valve movement.

Cylinder Head & Related Components for Cummins 6B Marine and Industrial EnginesCylinder Head & Related Components for Cummins 6BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BTA Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4B Marine and Industrial EnginesCylinder Head & Related Components for Cummins 4BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BTA Marine and Industrial Engines

6. Electrical System

- Alternator provides power to the battery and accessories.

- Starter motor cranks the engine during startup.

Starter & Alternator Related Components for Cummins 4B Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 4BT Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 4BTA Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6B Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6BT Marine & Industrial Engines

Starter & Alternator Related Components for Cummins 6BTA Marine & Industrial Engines

Why Cummins B Series Engines Are Widely Used

Final Thoughts

The Cummins B Series engine family remains a cornerstone of diesel power across industries. Whether used in marine, construction, trucking, or industrial settings, these engines continue to set the standard for performance, efficiency, and longevity.

Parts Catalog for Cummins 4B Marine & Industrial Engines

Parts Catalog for Cummins 4BT Marine & Industrial Engines

Parts Catalog for Cummins 4BTA Marine & Industrial Engines

Parts Catalog for Cummins 6B Marine & Industrial Engines

Parts Catalog for Cummins 6BT Marine & Industrial Engines

Parts Catalog for Cummins 6BTA Marine & Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588