Reasons You Might Need to Change Your Sea Water Pump on a Cummins Marine Engine

Introduction: The Role of the Sea Water Pump in Cummins Marine Engines

The sea water pump, also known as the raw water pump, is a critical component of your Cummins marine engine’s cooling system. Unlike a freshwater pump, which circulates coolant inside the engine, the sea water pump draws in raw water (seawater, lake water, or river water) and pushes it through the heat exchanger to cool the engine. After passing through the system, the water is expelled overboard.

Since Cummins marine engines operate in harsh saltwater environments, the sea water pump is exposed to extreme conditions, including corrosive saltwater, sand, debris, and marine growth. Over time, wear and tear, corrosion, blockages, and mechanical damage can cause the pump to fail, leading to engine overheating and potential failure.

Recognizing the warning signs of a failing sea water pump and replacing it before a breakdown is crucial for avoiding costly repairs and ensuring smooth engine operation. Below are the key reasons why you may need to replace the sea water pump on your Cummins marine engine.

1. Wear and Tear Over Time

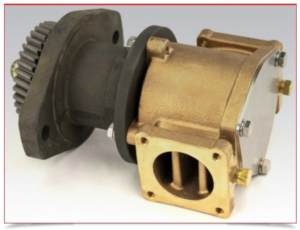

Sea Water Pump for Cummins 4BTA

Why Wear and Tear Affects Sea Water Pumps

Sea water pumps in Cummins marine engines are constantly running, pulling in thousands of gallons of seawater to cool the engine. The pump’s impeller, bearings, and seals undergo continuous movement and pressure, which causes them to wear out over time.

Factors that contribute to sea water pump wear include:

- High engine hours (long periods of operation)

- Frequent start-stop cycles in commercial, fishing, and recreational boats

- Aging impeller materials that degrade with heat and exposure to seawater

- Cavitation (formation of air pockets) that erodes pump components

Signs of a Worn-Out Sea Water Pump

If your Cummins sea water pump is worn out, you may notice:

✅ Reduced water flow from the exhaust outlet

✅ Higher-than-normal engine temperatures

✅ Louder operation (grinding or squealing noises)

✅ Impeller vanes that are cracked, broken, or missing

✅ Coolant system warning alarms on the dashboard

If the impeller or bearings are significantly worn down, replacing the sea water pump before it fails is essential to prevent engine overheating.

2. Corrosion from Saltwater Exposure

Why Corrosion is a Major Issue in Marine Engines

Unlike freshwater cooling systems, sea water pumps are constantly exposed to saltwater, which is highly corrosive. Over time, salt, minerals, and marine contaminants can corrode the pump housing, impeller, and internal components, leading to reduced efficiency and eventual failure.

Effects of Corrosion on a Sea Water Pump

When corrosion occurs inside the pump, it can lead to:

⚠️ Weakened or pitted metal components that may break under pressure

⚠️ Leaking seals and gaskets due to rust buildup

⚠️ Impaired impeller movement, reducing cooling efficiency

⚠️ Increased risk of pump failure and overheating

How to Identify a Corroded Sea Water Pump

Look for the following signs of corrosion on your Cummins marine engine’s sea water pump:

Rust or white salt deposits on the pump housing

Flaking or peeling metal surfaces

Stiff or locked-up impeller shaft due to rust buildup

Leaks forming at the pump’s base or fittings

If corrosion has compromised the pump’s structure or efficiency, replacing it before it fails completely is the best course of action.

3. Blockage Due to Debris and Marine Growth

How Blockages Form in Sea Water Pumps

Because raw water pumps pull in unfiltered seawater, they are prone to clogs caused by:

- Sand and silt from shallow water

- Algae and marine growth

- Shell fragments and debris

- Plastic bags or fishing line caught in the intake

If these materials accumulate inside the pump, they can restrict water flow and cause overheating.

Symptoms of a Blocked Sea Water Pump

If the pump is clogged, you may notice:

Reduced or weak water flow from the exhaust outlet

Steam or excessive heat coming from the exhaust

Unusual noises (whining or straining sounds)

Sudden engine overheating

To prevent blockages, regularly inspect and clean the sea strainer and replace the pump if blockages are recurring.

4. Damage from Impact or Cavitation

What Causes Physical Damage to a Sea Water Pump?

Although sea water pumps are built to last, they can suffer physical damage due to:

Impact damage from external forces (e.g., loose engine mounts, vibrations)

Running the pump dry, which destroys the impeller

Cavitation, caused by air bubbles forming in the pump due to air leaks or low water intake

When the impeller or housing is damaged, the pump may fail suddenly, causing immediate overheating and potential engine shutdown.

Signs of a Damaged Sea Water Pump

Look for the following indicators of physical damage:

Cracked or broken pump housing

Melted or deformed impeller blades (from dry running)

Loose or wobbling pulley shaft

Unusual vibrations when the pump is running

If the pump is severely damaged, replacing it immediately can prevent costly engine repairs.

5. Preventive Maintenance and Routine Replacement

Why Preventive Maintenance is Crucial

In marine applications, proactive maintenance is critical to avoiding breakdowns at sea. Many Cummins marine engine failures are due to cooling system issues, making regular pump inspections and timely replacements essential.

Best Practices for Sea Water Pump Maintenance

To extend the lifespan of your Cummins sea water pump:

✔️ Inspect the pump and impeller every 100-200 hours

✔️ Replace the impeller annually or if it shows signs of wear

✔️ Flush the cooling system regularly to remove salt and debris

✔️ Check for leaks, corrosion, or unusual noises during routine checks

✔️ Never run the engine dry—always ensure a steady water supply

Replacing the sea water pump before failure is a smart investment that prevents expensive repairs and downtime.

Conclusion: When Should You Replace Your Sea Water Pump?

A functioning sea water pump is essential for keeping your Cummins marine engine cool and running smoothly. If you experience reduced water flow, overheating, corrosion, blockages, or physical damage, replacing the pump before a breakdown occurs can save you thousands in repairs and prevent engine failure at sea.

Key Signs That You Need a New Sea Water Pump:

✅ Overheating despite full coolant levels

✅ Reduced or no water flow from the exhaust outlet

✅ Corrosion, rust, or leaks on the pump housing

✅ Noisy operation or excessive vibration

✅ Broken or missing impeller blades

Regular inspections and proactive replacements can ensure safe and reliable operation for your Cummins marine engine.

For high-quality replacement sea water pumps, trust Diesel Pro Power’s premium aftermarket marine engine parts.

Parts Catalog for Cummins Marine Engine

Sea water Pump Pump for 4B Cummins Marine Engine

Sea water Pump for 4BT Cummins Marine Engine

Sea water Pump for 4BTA Cummins Marine Engine

Sea water Pump for 6B Cummins Marine Engine

Sea water Pump for 6BT Cummins Marine Engine

Sea water Pump for 6BTA Cummins Marine Engine

Sea water Pump for QSB 5.9 Cummins Marine Engine

Sea water Pump for QSB 6.7 Cummins Marine Engine

Sea water Pump for QSB 7.0 Cummins Marine Engine

Sea water Pump for 6C Cummins Marine Engine

Sea water Pump for 6CT Cummins Marine Engine

Sea water Pump for 6CTA Cummins Marine Engine

Sea water Pump for QSC Cummins Marine Engine

Sea water Pump for QSL Cummins Marine Engine

Sea water Pump for QSM Cummins Marine Engine

Sea water Pump for NH855 Cummins Marine Engine

Sea water Pump for NT855 Cummins Marine Engine

Sea water Pump for KTA19 Cummins Marine Engine

Sea water Pump for KTA38 Cummins Marine Engine

Sea water Pump for KTA50 Cummins Marine Engine

Sea water Pump for QSK19 Cummins Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588