Parts for Caterpillar 3208 Non Turbo - Exhaust Section

Loading...

Loading... Parts for Caterpillar 3208 Non Turbo – Exhaust Section

The exhaust system of the Caterpillar 3208 non-turbo engine plays a critical role in maintaining performance, efficiency, and reliability. From manifolds to elbows and gaskets, every part must withstand extreme temperatures and constant vibration while helping direct exhaust gases safely out of the combustion chambers. At Diesel Pro Power, we provide a full catalog of Caterpillar 3208 exhaust components designed specifically for natural (non-turbo) and turbocharged variants of this engine, ensuring you have the right parts for both maintenance and complete rebuilds.

Exhaust Manifold for Caterpillar 3208 Natural and Turbo Engines

The exhaust manifold channels the hot gases from each cylinder into a common flow path before exiting through the exhaust system. On the 3208 engine, precision fit and durable construction are essential since leaks or cracks in the manifold can lead to performance loss, increased fuel consumption, and overheating of nearby components.

-

Applications: Fits both left or right bank of Caterpillar 3208 Natural and Turbo engines.

-

Durability: Cast from heat-resistant alloys that withstand thousands of hours of high-temperature operation.

-

Maintenance Tip: Regular inspection of manifold bolts and gaskets helps prevent leaks caused by thermal expansion cycles.

This manifold ensures proper exhaust scavenging and is engineered to meet or exceed original Caterpillar specifications.

Exhaust Elbow for Caterpillar 3208 Natural and Turbo Engines

The exhaust elbow is a key link between the manifold and the rest of the exhaust piping system. On many marine applications, the elbow is water-cooled to protect surrounding areas from extreme exhaust heat.

-

Configuration: Right bank water-cooled design.

-

Marine Focus: Designed specifically to operate in continuous-duty marine environments where heat management is critical.

-

Reliability: Water-cooled housing helps extend service life by reducing surface temperatures.

Even though often overlooked, the elbow is one of the most stressed parts of the system due to heat cycling and water flow. Ensuring a high-quality replacement helps maintain both safety and efficiency.

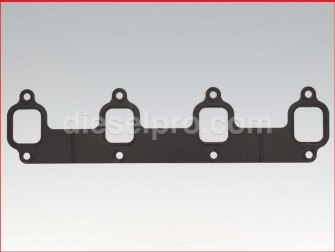

Exhaust Manifold Gaskets for Caterpillar 3208 Engines

Gasket for Turbo Models – 2N2754

For Caterpillar 3208 turbocharged engines, the exhaust manifold gasket provides a tight seal between manifold sections to prevent leakage of high-pressure exhaust gases.

-

Quantity Required: Four per engine.

-

Critical Role: Prevents energy loss from escaping gases and protects surrounding engine parts from hot gas leaks.

Gasket for Natural and Turbo Models – 9L8027

This gasket is located between the manifold and the block.

-

Applications: Works for both natural and turbocharged versions.

-

Fitment: Designed to handle constant heat expansion cycles.

-

Installation Note: Always replace gaskets when removing manifolds to avoid resealing issues.

Gasket for Turbo Manifold – 1214680

Specifically for the 3208T configuration, this gasket ensures secure sealing across high-pressure turbo applications.

-

Quantity Required: Four per engine.

-

Construction: High-temperature resistant material prevents blow-outs and maintains efficiency.

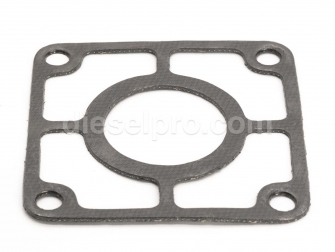

Gasket for Exhaust Manifold Elbow – 1072517

The elbow gasket ensures a leak-free connection between the manifold and the exhaust elbow.

-

Quantity Required: Two per engine.

-

Marine Advantage: Prevents water intrusion and exhaust leaks in marine applications where reliability is critical.

-

Service Tip: Replace during every elbow or manifold service to guarantee long-lasting performance.

Importance of the Exhaust System in the Caterpillar 3208

The exhaust system of the Caterpillar 3208 is more than just a passageway for gases—it directly impacts efficiency, performance, and emissions. A properly sealed and maintained exhaust system helps the engine:

-

Maintain Power Output – By directing gases smoothly, it prevents back pressure that can reduce horsepower.

-

Control Heat – Exhaust manifolds and elbows dissipate significant heat, preventing thermal damage to engine blocks and surrounding components.

-

Reduce Noise – The design helps in muffling the sound generated during combustion.

-

Improve Fuel Efficiency – Efficient exhaust scavenging ensures cylinders receive maximum fresh air for combustion.

-

Protect Marine & Industrial Equipment – Water-cooled exhaust elbows reduce risks of fire hazards and overheating in confined engine rooms.

Common Issues with Caterpillar 3208 Exhaust Components

Over years of heavy-duty operation, certain issues may arise with the exhaust system:

-

Cracked Manifolds: Repeated heating and cooling cycles can cause cast iron to crack.

-

Warped Surfaces: Overheating or improper installation may lead to manifold warping.

-

Leaking Gaskets: Gaskets deteriorate over time due to heat and vibration, leading to exhaust leaks.

-

Corrosion in Elbows: Saltwater marine environments often accelerate corrosion in exhaust elbows, especially in water-cooled versions.

-

Excessive Noise or Smoke: Symptoms often trace back to leaks in gaskets or failed manifold seals.

By replacing components at the first signs of failure, operators can prevent costly damage to the engine block, valves, and turbocharger assemblies.

Best Practices for Maintaining Caterpillar 3208 Exhaust Parts

-

Routine Inspections: Inspect manifolds, elbows, and gaskets every 1,000 operating hours or during scheduled overhauls.

-

Torque Bolts Properly: Uneven or excessive torque can cause warping or cracked manifolds.

-

Use New Gaskets: Always install fresh gaskets during disassembly and reassembly.

-

Check Water-Cooled Elbows: Flush regularly to prevent salt and mineral buildup that can reduce cooling efficiency.

-

Monitor Exhaust Temperatures: Abnormal rises may indicate blockages or leaks that need immediate correction.

Diesel Pro Power Advantage for Caterpillar 3208 Exhaust Parts

When sourcing exhaust components for the Caterpillar 3208, Diesel Pro Power provides unmatched advantages:

-

Global Shipping: Orders leave within 24 hours to over 180 countries worldwide.

-

Trusted by 40,000+ Customers: Operators across marine, industrial, and heavy-equipment sectors rely on our expertise.

-

Comprehensive Catalog: From manifolds and elbows to every type of gasket, all parts are available in one place.

-

Marine & Industrial Focus: Unlike general suppliers, we specialize in engines built for continuous heavy-duty use.

-

Expert Guidance: Our support team ensures compatibility with your specific Caterpillar 3208 configuration.

Applications of Caterpillar 3208 Exhaust Components

The Caterpillar 3208 has been widely used in:

-

Marine Propulsion Systems – Commercial fishing boats, tugboats, and work vessels.

-

Generators – Continuous-duty industrial generators where efficiency is critical.

-

Construction Equipment – Bulldozers, loaders, and cranes.

-

Agricultural Machinery – Tractors and harvesters requiring robust diesel performance.

In every application, the exhaust system ensures proper thermal management and efficient expulsion of gases, critical for long-term reliability.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588