Parts for Caterpillar 3208 Turbo - Cylinder Head Section

Loading...

Loading... Parts for Caterpillar 3208 Turbo – Cylinder Head Section

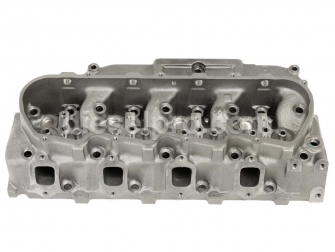

The cylinder head is one of the most critical assemblies on the Caterpillar 3208 Turbo engine. It houses the intake and exhaust valves, combustion chambers, fuel injector seating, and forms the sealed surface against the block to contain combustion pressures. A properly functioning cylinder head ensures smooth airflow, proper compression, and reliable power delivery for heavy-duty marine and industrial applications. At Diesel Pro Power, we provide a full range of brand-new cylinder heads, gasket sets, valve train components, and supporting hardware to keep your 3208T running at peak efficiency.

Complete Cylinder Head Assemblies for Caterpillar 3208 Turbo

Operators can choose between bare heads or fully assembled cylinder heads depending on their rebuild strategy:

-

Bare Cylinder Head – Supplied without valves, springs, or inserts. Ideal for technicians who want to reuse or customize valve train components. This option provides flexibility while ensuring a new casting free from cracks or warping.

-

Complete Cylinder Head with Valves and Springs – A ready-to-install solution that comes pre-loaded with valve train components. This reduces rebuild time and minimizes the risk of improper installation. It is particularly popular in fleet maintenance or when downtime must be kept to an absolute minimum.

Both styles are precision-engineered to meet OEM specifications for Caterpillar 3208 Natural and Turbocharged engines.

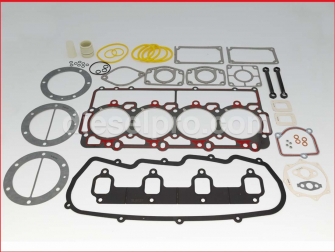

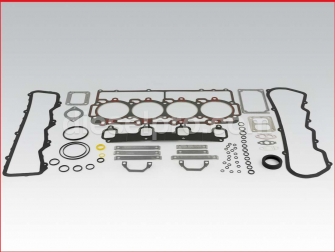

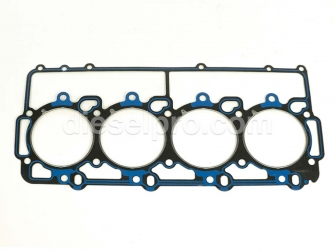

Cylinder Head Gasket Sets

Sealing between the head and block is essential for maintaining compression and preventing coolant or oil leaks. Diesel Pro Power offers multiple gasket configurations depending on the exhaust manifold design of your engine:

-

Single Manifold Gasket Set – Designed for engines equipped with a one-piece exhaust manifold. Ensures full sealing around combustion chambers and coolant passages.

-

Dual Manifold Gasket Set – Tailored for engines using two exhaust manifolds. Prevents leaks and ensures long-lasting durability under turbocharged operating pressures.

-

Individual Cylinder Head Gaskets – Available per head, offering a targeted replacement solution when only one side of the V-configuration requires service.

Each gasket is engineered from high-temperature composite materials to withstand the demands of turbocharged combustion cycles.

Overhaul Gasket Sets for Complete Rebuilds

For major engine work, an overhaul gasket set provides every necessary seal and gasket related to the cylinder head assembly. These kits cover engines configured with two-piece exhaust manifolds, ensuring that no component is overlooked during a rebuild. Using an overhaul set guarantees consistency across the engine and reduces the risk of future sealing failures.

Intake and Exhaust Valves

Valves regulate the breathing of the Caterpillar 3208 Turbo, controlling airflow into and out of the combustion chamber:

-

Intake Valves – Eight per engine. Built to withstand high pressures while maintaining precise sealing for compression and fuel delivery.

-

Exhaust Valves – Eight per engine. Constructed from heat-resistant alloys to handle extreme exhaust temperatures common in turbocharged engines.

-

Specialized Turbo Exhaust Valves – An upgraded design for turbocharged variants, offering enhanced durability for continuous high-load operation.

Replacing worn or burnt valves restores proper airflow and prevents power loss, excessive fuel consumption, and potential damage to pistons and cylinder heads.

Valve Guides and Inserts

Guides and inserts are essential to maintain correct valve alignment and seating:

-

Valve Guides – Ensure valves travel in a straight path, reducing wear and preventing misalignment. Separate guides are available for intake and exhaust valves.

-

Valve Inserts (Seats) – Hardened inserts pressed into the cylinder head to provide a durable sealing surface for valves. Intake and exhaust versions are available, with exhaust inserts designed to resist extreme thermal cycling.

Maintaining guides and inserts extends cylinder head life and ensures reliable sealing over thousands of operating hours.

Valve Springs and Retainers

The Caterpillar 3208 Turbo uses a dual-spring system for each valve:

-

Outer Springs – Provide primary force to close the valve quickly and securely.

-

Inner Springs – Add reinforcement, preventing valve float at high RPMs and under turbocharged boost.

-

Spring Retainers – Secure the valve springs in position, ensuring stability under high-load conditions.

Together, these components ensure valves operate in perfect timing with the camshaft, preventing loss of compression and engine misfires.

Valve Seals, Locks, and Related Hardware

Even the smallest components in the cylinder head system are critical:

-

Valve Seals – Prevent oil leakage into the combustion chamber, reducing smoke and improving fuel economy. Both intake and exhaust valves utilize steam seals for reliable operation.

-

Valve Locks (Keepers) – Hold the springs and retainers in place, preventing catastrophic valve train failure.

-

Push Rods – Transfer motion from the camshaft to the rocker arms, operating each valve with precise timing.

-

Lifters (Tappets) – Ride on the camshaft lobes and actuate the push rods. Proper lifter function is crucial for smooth valve operation.

Together, these small but essential parts ensure reliable valve timing, reduced oil consumption, and consistent power output.

Valve Cover Gaskets

Valve cover gaskets prevent oil leaks at the top of the cylinder head where rocker arms and valve train components operate. High-quality gaskets keep oil contained within the head, reducing contamination risks and protecting external engine components from oil exposure.

The Importance of Cylinder Head Maintenance on the 3208 Turbo

A turbocharged engine places additional stress on the cylinder head compared to naturally aspirated versions. Increased combustion pressures, higher temperatures, and faster valve cycles make inspection and maintenance critical. Common warning signs of head issues include:

-

Coolant leaks or oil mixing with coolant.

-

Excessive white smoke indicating gasket failure.

-

Loss of compression leading to reduced power.

-

Burnt or warped valves causing misfires.

By replacing worn components with quality parts from Diesel Pro Power, operators extend the life of their Caterpillar 3208 Turbo and avoid costly downtime.

Why Choose Diesel Pro Power for Caterpillar 3208 Cylinder Head Parts

When it comes to sourcing Caterpillar 3208 Turbo cylinder head components, operators worldwide rely on Diesel Pro Power. Here’s why:

-

Global Shipping – Orders ship within 24 hours to over 180 countries.

-

Proven Customer Trust – More than 40,000 satisfied customers rely on our catalog and expertise.

-

Complete Coverage – From full cylinder heads to valves, gaskets, and seals, everything is available in one convenient catalog.

-

Expert Support – Our team helps ensure compatibility with your exact 3208T configuration, whether for marine propulsion or industrial power generation.

-

Marine & Industrial Focus – Unlike general suppliers, Diesel Pro Power specializes in heavy-duty engines built for continuous operation under demanding conditions.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588