Parts for Caterpillar 3406C - Cylinder Head Section

Loading...

Loading... -

Cylinder Head for Caterpillar 3406 and 3406C

1105099

Bare and with Direct InjectionPrice: $ 2,644.49 -

Cylinder Head for Caterpillar 3406 and 3406C

1105097

Bare and with precombustion ChamberPrice: $ 2,644.49 -

Cylinder Head for Caterpillar 3406 engines

1105099V

New - head with valves and springs

Direct Injection Engines

Price: $ 3,762.69 -

Cylinder Head for Caterpillar 3406 engines

1105097V

New - head with valves and springs.

Pre combustion Chamber Engines

Price: $ 3,762.69 -

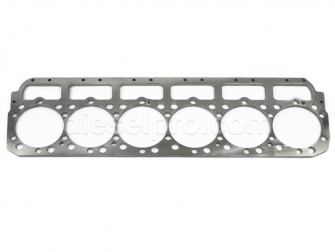

Cylinder head Spacer plate for Caterpillar 3406 engines

6I2981

Spacer plate locate between the head and the block.

Price: $ 592.14 -

-

-

-

Head Bolt for Caterpillar 3406, 3408 and 3412 engines

2H3750

3/4 - 16 Inches Thread Size 7 1/2 Inches Total LengthPrice: $ 11.39 -

-

Intake Valve for Caterpillar 3406, 3408 & 3412 engines

1152368

For engines with Arrangenment #s 1243400, 1302549, 1790769, 1790770, 1790771, 1855890, 1W0733, 1W3500, 4N2247, 4N2247, 4W1146, 7W7584, 4P6983, 4P6984, 1031819, 1031820, 1160052, 1160053, 1797010, 1797011, 1797012 & 1797013

Price: $ 21.36 -

Exhaust Valve for Caterpillar 3406, 3408 & 3412 engines

1152367

For engines with Arrangement #s 1243400, 1302549, 1790769, 1790770, 1790771, 1855890, 1W0733, 1W3500, 4N2247, 4N2247, 4W1146, 7W7584, 4P6983, 4P6984, 1031819, 1031820, 1160052, 1160053, 1797010, 1797011, 1797012 & 1797013

Price: $ 21.36 -

-

Rotocoil for Caterpillar 3406, 3406B and 3406C engines

4W2474

Intake and Exhaust Valve

For Dual Spring Application

Price: $ 7.10 -

Rotocoil for Caterpillar 3406 and 3408 engines

6N7154

Intake and Exhaust Valve

Precombustion Chamber engines

Price: $ 7.25 -

-

-

Exhaust Valve Insert for Caterpillar 3406, 3408 and 3412 engines

1W5283

Exhaust Valve SeatPrice: $ 11.16 -

Intake Valve Insert for Caterpillar 3406, 3408 and 3412 engines

4N5893

Intake Valve SeatPrice: $ 7.43 -

-

Valve Spring for Caterpillar 3406, 3406B, 3406C engines

4W2472

Inner Spring, Dual Spring applicationPrice: $ 5.16 -

Valve Spring for Caterpillar 3406, 3406B, 3406C engines

4W2471

Outher Spring, Dual Spring applicationPrice: $ 4.70 -

-

-

-

Precombustion Chamber Gasket for Caterpillar 3400 serie engines

4N7253

One per ChamberPrice: $ 3.54 -

-

-

-

Parts for Caterpillar 3406C – Cylinder Head Section

The Caterpillar 3406C engine remains one of the most respected and widely used powerplants in the marine and industrial sectors. Known for its durability, straightforward design, and ability to deliver continuous-duty power, the 3406C is a benchmark in heavy-duty diesel performance. A vital part of maintaining this performance lies in the cylinder head assembly and all of its related components.

This catalog provides a complete breakdown of Caterpillar 3406C cylinder head parts, including new heads, gaskets, valves, springs, rotocoils, guides, and hardware. Each component plays an essential role in keeping your 3406C operating with maximum efficiency and reliability. Diesel Pro Power supplies these parts worldwide, trusted by 40,000+ satisfied customers in more than 180 countries.

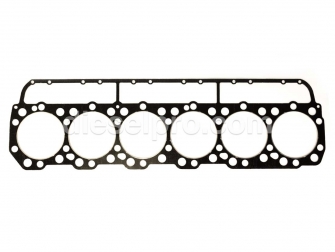

Cylinder Heads for Caterpillar 3406C

The cylinder head is the heart of the top-end system of the Caterpillar 3406C. It seals the combustion chamber, directs airflow, manages fuel delivery (in direct injection engines), and holds critical components like valves, springs, and precombustion chambers. Because Caterpillar designed different variations of the 3406C to support direct injection and precombustion chamber systems, selecting the right head is crucial.

Bare Cylinder Head Options

-

Cylinder Head for Caterpillar 3406 and 3406C (Bare, Direct Injection)

A new bare casting designed for direct injection engines. Ideal for rebuild projects where the customer wishes to transfer existing valves and springs or install new valve components separately. -

Cylinder Head for Caterpillar 3406 and 3406C (Bare, Precombustion Chamber)

This version is machined to accept precombustion chambers, offering flexibility for engines configured for indirect injection. The head is bare, allowing for precise customization with new valves, springs, and inserts.

Fully Assembled Cylinder Heads

-

Cylinder Head for Caterpillar 3406 Engines (Direct Injection)

Delivered fully assembled with valves and springs, this option provides a plug-and-play solution that reduces installation time. It is designed specifically for direct injection fuel systems. -

Cylinder Head for Caterpillar 3406 Engines (Precombustion Chamber)

A complete head with valves and springs installed, designed for precombustion chamber configurations. This simplifies top-end service while ensuring OEM-level reliability.

Cylinder Head Hardware and Gaskets

Cylinder heads cannot perform without the supporting hardware that ensures proper sealing and secure mounting.

Spacer Plate

-

Cylinder Head Spacer Plate

Installed between the head and the block, the spacer plate ensures correct compression and sealing. It acts as a barrier, compensating for wear or dimensional tolerances, and prevents combustion gases from damaging the block surface.

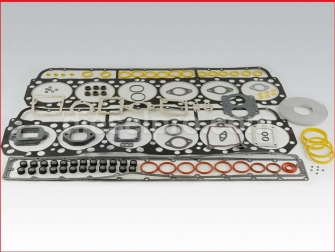

Cylinder Head Gasket Sets

-

Cylinder Head Gasket Set (3406B and 3406C)

Includes all required gaskets and seals for a complete head installation. Designed to maintain proper compression ratios and withstand the high combustion pressures of the 3406C. -

Cylinder Head Gasket (Single)

Offered individually for smaller repairs where only a replacement gasket is required.

Head Bolts and Washers

-

Head Bolts for Caterpillar 3406, 3408, and C-Series Engines

Available in multiple thread sizes and lengths, these bolts deliver the clamping force necessary to keep the cylinder head sealed. Using new bolts is critical, as reusing old ones can lead to head gasket failure. -

Head Bolt Washers

Washers distribute torque evenly, preventing bolt stretch and ensuring correct compression across the cylinder head.

Valves and Related Components

Valves are among the most stressed components in any diesel engine. They endure extreme temperatures, high combustion pressures, and constant cycling. Caterpillar 3406C valves are built for reliability but require periodic replacement.

Intake and Exhaust Valves

-

Intake Valves for Caterpillar 3406, 3408 & 3412 Engines

These allow air to enter the combustion chamber. Correct seating ensures maximum airflow and fuel efficiency. -

Exhaust Valves for Caterpillar 3406, 3408 & 3412 Engines

Designed to withstand extreme exhaust temperatures, these valves expel burnt gases effectively.

Valve Rotocoils

Rotocoils are essential in preventing valve hot spots by ensuring the valves rotate slightly during operation. This extends service life.

Valve Guides and Inserts

-

Valve Guides

Ensure precise alignment of the valves during operation, minimizing wear. Available for both direct injection and precombustion designs. -

Valve Inserts (Seats)

Intake and exhaust valve inserts provide a durable seating surface, protecting the head from erosion caused by high-pressure combustion gases.

Valve Springs

-

Outer and Inner Valve Springs

The 3406C uses dual-spring configurations in certain models, combining inner and outer springs for added stability and vibration control.

Precombustion Chamber Components

For engines configured with precombustion chambers, additional parts are required:

-

Precombustion Chambers

Inserted into the cylinder head, they assist in the controlled ignition of fuel-air mixtures. -

O-Rings, Gaskets, and Washer Seals

These seals prevent combustion gases and coolant from leaking around the precombustion chamber insert.

Valve Train Components

The cylinder head assembly also integrates critical valve train components that translate camshaft motion into valve actuation.

-

Push Rods

Transmit force from the camshaft lifter to the rocker arms. Precision straightness is critical for smooth operation. -

Valve Lifters (Tappets)

Sit between the camshaft and push rods, providing smooth motion transfer. -

Valve Locks

Secure the valve spring retainers, holding valves in place under extreme stress.

Importance of Cylinder Head Maintenance

Cylinder heads are often the first area to show stress in heavy-duty Caterpillar engines. Issues such as cracked castings, worn valve seats, or head gasket leaks can compromise engine performance. Proactive maintenance and replacement of key components ensures:

-

Consistent compression ratios

-

Prevention of coolant or oil leaks

-

Protection against valve failure

-

Restoration of factory-level performance

Caterpillar 3406C in Marine and Industrial Applications

The 3406C is used extensively in:

-

Marine propulsion systems – fishing vessels, tugboats, workboats, and transport ships.

-

Generators – continuous-duty power generation for industrial facilities, oil fields, and remote operations.

-

Construction equipment – powering loaders, cranes, and drilling equipment.

-

Industrial pumps and compressors – supporting high-demand environments.

In all of these applications, downtime is costly. Having reliable access to cylinder head parts ensures reduced turnaround time and maximized operational efficiency.

Why Choose Diesel Pro Power for Caterpillar 3406C Cylinder Head Parts

-

Global Reach – Fast, reliable shipping to over 180 countries.

-

Trusted by 40,000+ Customers – A proven reputation in marine and industrial diesel engines.

-

Comprehensive Catalog – Every part you need in one place, from full cylinder heads to the smallest valve locks.

-

Marine & Industrial Focus – Unlike general suppliers, Diesel Pro Power specializes in continuous-duty diesel applications.

-

Expert Support – Our team assists with identifying the correct head, gasket set, or valve based on your arrangement number or serial prefix.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588