Parts for Caterpillar 3406E - Camshaft Section

Loading...

Loading... Caterpillar 3406E Camshaft and Related Components

The Caterpillar 3406E engine is widely recognized for its durability, high horsepower output, and reliability across on-road trucking, construction, and industrial applications. One of the most critical components in this engine’s performance is the camshaft and its related parts. The camshaft controls valve timing and ensures precise synchronization between the intake, compression, combustion, and exhaust cycles. When combined with properly fitted bushings, gears, dowels, and valve lifters, the camshaft system allows the 3406E to deliver the efficiency and power it’s known for.

Below is a detailed look at the camshaft section of the Caterpillar 3406E parts catalog, including each major component and its role in maintaining engine performance.

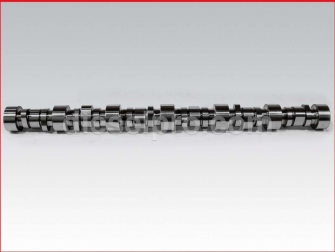

Camshaft for Caterpillar 3406E Engines

The camshaft is the centerpiece of this section. In the 3406E, it’s designed to handle high loads and long operating hours while maintaining precise timing of the valves. A properly functioning camshaft ensures:

-

Accurate valve timing – guarantees fuel-air mixture enters and exhaust gases exit at the right intervals.

-

Durability under heavy load – built to withstand extreme stresses in heavy-duty trucking and industrial environments.

-

OEM-quality performance – replacement camshafts built to Caterpillar specifications ensure a perfect fit and long service life.

A new camshaft is often required during a complete overhaul or when significant wear is detected. Excessive lobe wear or cracks can lead to poor fuel economy, reduced power, and engine misfires.

Camshaft Dowel Key for Caterpillar 3406E

The dowel key locks the camshaft gear securely in place, preventing any slippage or misalignment during engine operation. Even though it’s a small component, it plays a critical role in maintaining synchronization.

-

Precise alignment – ensures the gear-to-camshaft connection stays true.

-

Simple installation – designed to slot into place for reliable performance.

-

Essential for rebuilds – often replaced alongside the camshaft gear during top-end rebuilds.

Replacing a worn dowel key prevents unnecessary stress on the camshaft gear and reduces the risk of catastrophic timing issues.

Camshaft Gear for Caterpillar 3406E

The camshaft gear transfers rotational energy from the crankshaft to the camshaft, keeping valve movement perfectly timed with piston travel.

-

Durable construction – built to withstand constant load transfer.

-

Critical for timing – ensures intake and exhaust valves open at precise points in the combustion cycle.

-

Common wear part – over time, teeth can wear or chip, leading to performance loss.

For fleets and operators, replacing a worn camshaft gear is vital to protect both the camshaft and overall engine timing.

Camshaft Bushings for Caterpillar 3406E

Camshaft bushings provide smooth rotation of the camshaft inside the block, reducing metal-to-metal contact. For the 3406E, multiple bushing sizes are available to accommodate both standard fits and engines that require machining and resizing.

Standard Camshaft Bushings

-

Designed for engines where the housing is still within factory specification.

-

Provide OEM-level support and wear resistance.

Oversize Camshaft Bushings (.010, .030, .050, .070)

-

Used when the engine block bore has been machined or worn beyond standard limits.

-

Allow technicians to restore proper clearances without replacing the block.

-

Offered in multiple increments to match varying levels of wear.

Having the correct bushing fit is essential to prevent camshaft misalignment, which can lead to premature wear and failure. A complete rebuild often includes replacing all seven bushings in the engine.

Valve Lifters for Caterpillar 3406E

Valve lifters, also known as tappets, transfer the camshaft lobe motion to the pushrods and rocker arms, ultimately controlling valve movement. In the 3406E, durable lifters are essential to handle high valve spring pressures and long operating hours.

-

Smooth operation – reduces friction and wear between cam lobes and lifters.

-

Durability – built to withstand the high stresses of heavy-duty operation.

-

Wide compatibility – lifters also fit related Caterpillar engines such as the 3408 and 3412, offering versatility in multi-engine fleets.

Replacing valve lifters along with a camshaft ensures a balanced wear pattern and extends the overall life of the valve train.

Why Choose Diesel Pro Power for Caterpillar 3406E Camshaft Parts

-

Trusted by 40,000+ customers worldwide – Diesel Pro Power has built its reputation on delivering reliable Caterpillar engine parts quickly and accurately.

-

OEM-quality replacements – Every camshaft, gear, dowel, bushing, and lifter is manufactured to precise Caterpillar specifications for perfect fit and performance.

-

Fast worldwide shipping – downtime costs money, and Diesel Pro ensures that fleets, owner-operators, and industrial operations get back online faster.

-

Organized 3406E catalog – our catalog is structured for clarity, making it easy to locate the right component the first time.

-

Expert technical support – dedicated specialists can help identify the correct camshaft configuration and related components for any 3406E build.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588