Parts for Caterpillar 3406E - Cylinder Head Section

Loading...

Loading... Cylinder Head Parts for Caterpillar 3406E Engines

The Caterpillar 3406E is one of the most recognized heavy-duty diesel engines ever produced, widely used in trucking, marine, and industrial applications. Known for its durability and power, the 3406E relies heavily on a properly functioning cylinder head assembly to maintain compression, manage airflow, and regulate combustion.

This catalog provides a complete breakdown of Caterpillar 3406E cylinder head components, including bare and assembled heads, gaskets, spacers, valves, valve train parts, injector sleeves, seals, and hardware. All components are designed to meet OEM specifications, ensuring proper fit and long-lasting performance. Diesel Pro Power supports 40,000+ satisfied customers worldwide, supplying genuine and aftermarket cylinder head parts for Caterpillar engines with global shipping and expert technical guidance.

Complete Cylinder Heads for Caterpillar 3406E

Cylinder heads for the Caterpillar 3406E can be purchased as bare castings or as fully assembled heads including valves, springs, and retainers.

-

Bare Cylinder Head – Ideal for shops performing a full rebuild where valves and springs will be upgraded or replaced individually.

-

Assembled Cylinder Head – Supplied with intake and exhaust valves, springs, seats, and retainers pre-installed. This option saves time during installation and is recommended for fleet operators or end users who need minimal downtime.

Cylinder heads for the 3406E may also be compatible with certain C15 and C18 engines, depending on serial number prefixes such as 3VH, 9WR, RLA, BEM, MGS, C1J, CKH, CYN, NAX, and NAY. Always confirm compatibility with your arrangement number or serial code.

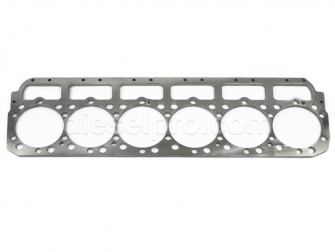

Spacer Plates and Head Gaskets

The interface between the cylinder head and engine block is critical. Spacer plates and gaskets provide the sealing necessary to maintain compression while preventing coolant or oil leaks.

-

Spacer Plates – Installed between the head and block to fine-tune compression and prevent head distortion. Spacer plates are required in many rebuilds and are available for both standard 3406 and 3406E configurations.

-

Cylinder Head Gaskets – Designed to withstand extreme combustion pressures and thermal cycling. Gaskets are available as single replacements or as part of comprehensive top-end rebuild kits. Options exist for 3406E-only as well as multi-application gaskets for 3406E, C15, and C18 engines.

Proper gasket selection is vital for maintaining compression ratio, preventing blow-by, and ensuring engine longevity.

Head Bolt Kits and Fasteners

Cylinder head bolts are subject to massive stress, holding the head tightly against the block under thousands of pounds of combustion force.

-

Complete Head Bolt Kits – Provide all bolts and washers required for a cylinder head installation. Recommended when replacing the head, as reusing old bolts can result in uneven torque or premature failure.

-

Individual Cylinder Head Bolts – Available for direct replacement. Typically measured by length and grade, with 7.6-inch bolts common in the 3406E.

-

Head Bolt Washers – Hardened to withstand clamping pressure and prevent bolt stretch. Available for 3406E as well as compatible Caterpillar 3408, 3412, C15, and C18 engines.

For best results, bolts should always be torqued in sequence using Caterpillar’s specifications.

Intake and Exhaust Valves

Valves regulate airflow in and out of the combustion chamber. A properly sealing valve system ensures maximum power and fuel efficiency.

-

Intake Valves – Control fresh air intake, typically twelve per engine.

-

Exhaust Valves – Release exhaust gases, also twelve per engine.

Both intake and exhaust valves are precision-machined from heat-resistant alloys. In performance terms, a poor seal at the valve face can drastically reduce compression and cause misfires, making regular inspection and replacement critical during overhauls.

Rotocoils, Valve Guides, and Inserts

Supporting components help valves operate smoothly and seat correctly.

-

Rotocoil Assemblies – Designed to slowly rotate valves during operation, ensuring even wear. Typically twenty-four are required per engine.

-

Valve Guides – Maintain precise valve alignment, preventing side-loading that can wear out the valve seat. Commonly replaced during head reconditioning.

-

Valve Seat Inserts – Hardened metal rings pressed into the head to provide a durable sealing surface. Intake and exhaust inserts are installed in sets of twelve each.

Replacing worn guides and inserts extends the life of new valves and prevents costly head damage.

Valve Springs, Seats, and Locks

The spring assembly ensures valves open and close under proper tension.

-

Dual-Spring System – The 3406E commonly uses inner and outer springs for redundancy and stability at high RPM.

-

Spring Seat Washers – Provide a flat, stable surface between the spring and cylinder head.

-

Valve Locks – Secure valves to retainers. Installed two per valve, these tiny components are crucial for keeping the valve assembly intact under extreme operating conditions.

Weak or broken springs can result in valve float, loss of power, and in severe cases, piston-to-valve contact.

Injector Sleeves and Seals

Fuel injectors in the 3406E rely on sleeves and sealing components to prevent leaks and maintain fuel atomization.

-

Injector Sleeves – Pressed into the cylinder head to isolate coolant from the injector body. Six are required per engine.

-

Seal Kits – Provide O-rings and seals for injector sleeves, ensuring no fuel or coolant cross-contamination.

Injector sleeve maintenance is vital to prevent hydro-locking or fuel dilution in the cooling system.

Valve Stem Seals

Valve stem seals prevent oil from entering the combustion chamber.

-

Exhaust Valve Seals – Installed twenty-four per engine, these seals regulate lubrication along the valve stem while keeping oil out of the exhaust system.

Worn or cracked seals often cause blue smoke on startup and higher oil consumption, making them a common replacement item during head service.

Valve Cover Gaskets and Top-End Sealing

The final layer of protection comes from valve cover gaskets.

-

Valve Cover Gaskets – Provide an oil-tight seal for the top of the head. Replacing the gasket is recommended whenever the cover is removed.

Proper gasket fitment prevents leaks that could cause oil loss or contamination of surrounding components.

Applications of Caterpillar 3406E Cylinder Heads

The 3406E cylinder head assembly is found in a wide variety of applications:

-

Highway Trucks – Freightliners, Peterbilts, Kenworths, and other heavy-duty trucks relied on the 3406E for millions of miles of service.

-

Industrial Equipment – The 3406E powered generators, pumps, and heavy-duty construction machinery.

-

Marine Applications – Some variants were marinized for propulsion and auxiliary power systems.

Because of these diverse applications, head designs evolved to meet varying emission standards, horsepower ratings, and fuel delivery systems.

Why Choose Diesel Pro Power for Caterpillar 3406E Cylinder Head Parts

Global Reach – Diesel Pro Power offers fast, reliable shipping to more than 180 countries, ensuring that no matter where your operation is located, replacement parts for your Caterpillar 3406E are within reach. Whether you manage a trucking fleet in North America, a power generation plant in South America, or marine engines in Asia, our logistics network ensures minimal downtime and dependable delivery.

Trusted by 40,000+ Customers – Over four decades of serving customers has built Diesel Pro Power into one of the most reliable names in heavy-duty diesel parts. With more than 40,000 satisfied clients worldwide, our reputation is grounded in consistent quality, reliable order fulfillment, and customer service that goes beyond the sale.

Complete Catalog – From fully assembled cylinder heads to the smallest consumables like valve locks or seals, every part you need for a Caterpillar 3406E top-end rebuild is in one place. Our catalog is carefully organized by engine model and component type, making it simple to locate exactly what you need without wasting time searching multiple vendors.

Marine & Industrial Focus – Unlike suppliers who cater primarily to automotive markets, Diesel Pro Power specializes in engines built for continuous-duty cycles. This means we understand the demands of 3406E engines used in marine propulsion, power generation, and heavy equipment. Our parts and technical resources are selected and tested with these rigorous environments in mind.

Expert Support – Our experienced team provides personalized assistance to ensure you get the correct components for your engine. From verifying compatibility with your specific serial number or arrangement code to advising on proper installation practices, Diesel Pro Power helps eliminate costly errors. Whether you are a professional rebuilder, fleet manager, or equipment operator, you’ll have a knowledgeable partner guiding you through the process.

Commitment to Reliability – Every cylinder head component we supply is manufactured to meet or exceed OEM standards. By sourcing parts that maintain factory-level performance, Diesel Pro Power helps customers extend engine life, reduce maintenance costs, and maximize uptime.

One-Stop Solution for 3406E Engines – Beyond cylinder heads, Diesel Pro Power provides a full range of supporting parts—gaskets, cooling components, fuel system parts, and more—allowing you to consolidate purchases and maintain consistency across your rebuild projects.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588