Parts for Caterpillar 3412B - Oil Section

Loading...

Loading... Caterpillar 3412B Oil System Parts Catalog

The Caterpillar 3412B engine is a legendary member of the 3400-series, designed for heavy-duty performance in marine propulsion, offshore platforms, mining, drilling, construction, and large-scale industrial power generation. At the heart of its long-lasting durability is a robust lubrication system. The oil system ensures that every moving component is protected against wear, friction, and overheating.

This catalog provides a complete look at the oil system components for the Caterpillar 3412B, with a focus on reliability, compatibility, and performance. From oil pumps and cooler cores to gaskets, seals, and maintenance tools, every item is designed to help operators keep their engines running at peak efficiency.

Importance of the Oil System in the Caterpillar 3412B

The oil system is one of the most critical subsystems in the Caterpillar 3412B. It performs several key functions:

-

Lubrication: Reduces metal-to-metal contact between moving parts such as crankshaft bearings, camshafts, connecting rods, and pistons.

-

Cooling: Carries heat away from high-stress components, particularly pistons and cylinder walls.

-

Cleaning: Removes contaminants, soot, and debris that can accumulate during operation.

-

Sealing: Helps maintain tight clearances, especially around piston rings, preventing loss of compression.

-

Corrosion Protection: Provides a thin protective film on metal surfaces to reduce oxidation and corrosion.

Without a properly functioning oil system, the 3412B engine would be prone to catastrophic failure. A seized crankshaft, burnt bearings, or scored liners are just a few examples of failures caused by inadequate lubrication.

Oil Pump for Caterpillar 3412B Engines

The oil pump is the heart of the lubrication system. In the Caterpillar 3412B, the oil pump draws oil from the pan and delivers it under pressure to every part of the engine.

Functions of the Oil Pump

-

Maintains oil pressure across a wide range of operating conditions.

-

Supplies constant lubrication to bearings, gears, and moving assemblies.

-

Ensures oil reaches upper components like rocker arms and valve trains.

-

Works with bypass valves to regulate flow during cold starts and high-load conditions.

Oil Pump Design for the 3412B

The 3412B oil pump is a gear-type positive displacement pump, meaning it delivers a fixed volume of oil for every revolution. This ensures constant lubrication regardless of engine RPM. The pump’s design has been engineered for long service life and minimal wear, even in the most demanding applications such as marine propulsion or mining operations.

Common Oil Pump Issues

-

Wear on internal gears: Causes pressure loss.

-

Relief valve sticking: Leads to fluctuating oil pressure.

-

Cavitation: Can occur if oil levels are low or suction is restricted.

-

Contamination: Sludge or metallic debris can damage gears and reduce performance.

Regular inspection and timely replacement of the oil pump are crucial to prevent bearing damage and engine downtime.

Oil Cooler Core for Caterpillar 3412B Engines

The oil cooler is another essential part of the system. As the 3412B operates under heavy loads, the oil absorbs tremendous heat. Without cooling, the oil would lose its viscosity and fail to protect engine components.

Functions of the Oil Cooler

-

Maintains optimal oil temperature (typically between 180–200°F).

-

Prevents oil breakdown under high heat.

-

Helps maintain consistent oil pressure.

-

Extends oil and component life.

Oil Cooler Core Design

The oil cooler for the 3412B is a tube-and-shell design, where engine oil flows through passages while coolant circulates around it. Heat is transferred from the oil to the coolant, which then carries it away to the radiator or heat exchanger.

Oil Cooler Maintenance

-

Inspect for leaks, especially at seals and fittings.

-

Clean coolant passages regularly to prevent scaling.

-

Replace seals and O-rings during servicing.

-

Monitor oil temperature gauges to detect early signs of cooler failure.

A failing cooler can cause oil to overheat, resulting in reduced lubrication efficiency and even bearing failure.

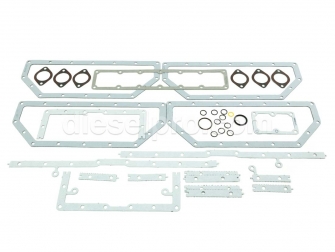

Oil Cooler Installation Kits

When replacing or servicing the oil cooler, installation kits are indispensable. These kits typically include:

-

Mounting brackets and hardware.

-

Seals and O-rings.

-

Gaskets.

-

Fasteners designed to handle high pressure and temperature.

By using a complete kit, operators ensure that the cooler is installed securely and leak-free. Piecing together hardware from various sources can result in improper sealing, leading to oil or coolant leaks.

Seals and O-Rings for Oil Coolers

Seals and O-rings may seem like small components, but they play a vital role in preventing oil leaks and cross-contamination between oil and coolant.

Applications in the 3412B Oil System

-

Seals are used at cooler connections.

-

O-rings provide pressure-tight fittings at critical joints.

-

Prevent loss of oil pressure and ensure system integrity.

Maintenance Tips

-

Replace seals and O-rings whenever a cooler or pump is serviced.

-

Avoid reusing old seals—they harden over time and lose elasticity.

-

Use proper torque specifications to avoid damaging sealing surfaces.

Oil Pan Gaskets for the Caterpillar 3412B

The oil pan gasket ensures a tight seal between the oil pan and the engine block. In a 3412B, this is particularly important since the oil pan holds a large volume of oil necessary to keep this massive V12 running smoothly.

Oil Pan Gasket Features

-

Designed to handle high vibration and thermal expansion.

-

Constructed from composite or multi-layered materials for durability.

-

Resists oil seepage, even under pressure.

Common Issues

-

Gasket wear leads to leaks at the oil pan flange.

-

Over-torquing bolts can crush the gasket.

-

Heat cycles cause gasket hardening and shrinkage.

Replacing the oil pan gasket during major overhauls or whenever leaks appear is essential to maintaining proper oil levels.

Oil Filter Removal Tools

Even the best oil system parts require regular servicing. The oil filter is designed to capture soot, metal shavings, and contaminants, preventing them from circulating through the engine. A proper filter removal wrench makes maintenance faster and safer.

Benefits of Using the Correct Tool

-

Ensures proper grip on large filters.

-

Prevents damage to the filter housing.

-

Speeds up oil change procedures.

For engines like the 3412B, which hold large volumes of oil, timely filter changes are crucial to extending both oil life and engine life.

Maintenance Best Practices for the Caterpillar 3412B Oil System

To maximize engine performance and longevity, operators should adhere to strict maintenance schedules.

Oil Change Intervals

-

Marine Engines: Every 250–300 hours of operation.

-

Industrial Engines: Based on fuel quality and load, typically 250–400 hours.

-

Heavy Load/Mining Applications: More frequent changes may be required due to dust and contaminants.

Inspection Checklist

-

Check oil pressure gauges daily.

-

Inspect oil levels before operation.

-

Look for leaks around gaskets, seals, and coolers.

-

Monitor oil color and viscosity—milky oil may indicate coolant contamination.

-

Replace filters at every oil change.

Applications of the Caterpillar 3412B Oil System

The oil system components listed here are used in engines powering:

-

Marine Vessels: Tugboats, ferries, fishing trawlers, cargo ships.

-

Mining Equipment: Excavators, haul trucks, drilling rigs.

-

Oil & Gas: Offshore drilling platforms and pumping stations.

-

Construction: Cranes, large bulldozers, and earthmovers.

-

Power Generation: Industrial generators providing continuous electricity in remote areas.

Each application demands maximum reliability, making proper oil system maintenance critical.

Why Buy Caterpillar 3412B Oil System Parts from Diesel Pro Power

When it comes to sourcing oil pumps, coolers, gaskets, and seals for the Caterpillar 3412B, Diesel Pro Power is the trusted choice.

Trusted Worldwide

Over 40,000 satisfied customers in more than 180 countries depend on Diesel Pro Power. From shipping fleets in Asia to mining operators in South America, our reach is truly global.

Premium Quality

Every oil pump, cooler core, gasket, and seal is manufactured to meet or exceed Caterpillar performance standards.

Fast Global Shipping

We understand downtime is costly. That’s why we offer expedited worldwide delivery, minimizing downtime for operators.

Dedicated Catalog

Our Caterpillar 3412B catalog is organized by system and component, making it simple to find exactly what you need.

Expert Support

Our specialists provide technical guidance to help operators select the correct pump, cooler, gasket, or seal. Whether you are rebuilding a marine propulsion engine or maintaining a power generator, our team ensures you get the right part the first time.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588